Congratulations! A famous woodworker wants to come and visit your shop.

[poll id=”4″]

Congratulations! A famous woodworker wants to come and visit your shop.

[poll id=”4″]

Look in most woodworking shops, and, no doubt, you’ll find a pretty oddball collection of tools. Sure, there are the basics – a table saw, band saw, router, you know, the usual.

Look in most woodworking shops, and, no doubt, you’ll find a pretty oddball collection of tools. Sure, there are the basics – a table saw, band saw, router, you know, the usual.

But, I’d wager you’d also find a number of tools designed to accomplish some very specific tasks –hollow chisel mortisers, specialized miter sleds, heavy metal tennoning jigs. There is no doubt that these tools are very good at what they do, but some can be quite expensive. And, in some cases, they get used only a few times a year at most.

That’s why woodworkers typically build jigs to meet these needs. There are some standard designs out there, and many of these jigs are cobbled together for one-time use and later collect dust on an out-of-the-way shelf.

But, that’s not the case for Niki Avrahami. If you have ever visited the Woodworker’s Website Association, WoodNet or many other woodworking message boards, you may have read about the ingenious array of jigs made by the woodworker from Poland.

From some very humble beginnings as a woodworker (his first project was a tissue box holder for his wife back in 1995), Niki has expanded his knowledge of the craft, and has taken his ingenuity to new heights.

From some very humble beginnings as a woodworker (his first project was a tissue box holder for his wife back in 1995), Niki has expanded his knowledge of the craft, and has taken his ingenuity to new heights.

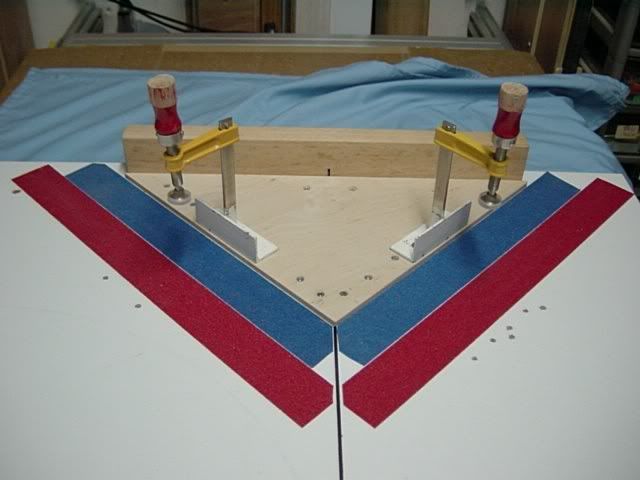

Small parts cutting jigs. Fence stops. Router lifts. If there’s a need, Niki has built a jig to satisfy it.

His thought process is very simple and straightforward. “Usually, I think of a jig because of three reasons; accuracy, repeatability and, last but not least, safety. That, in my opinion, is very important to any woodworker.”

The jigs he builds look somewhat complicated at first blush, but they are pretty straightforward and are made of readily available materials. While a typical jig takes Niki about three hours to construct, his meticulous photographic documentation adds considerable time to the process. “For a jig, I’ll take 50 to 150 pictures. Later, I’ll select the best of all of those for posting.”

His work is starting to catch the attention of woodworking publications. Wood magazine recently featured his 45 degree mitering sled as the best shop tip of the month. Previous editions have also featured some of the creative ideas to come from his simple garage shop.

Just as a proud parent won’t select a favorite child, Niki actually uses most of his jigs while building his projects. “What’s my favorite jig? That’s a difficult question. I think that I use all of them in almost every project because most of the steps are very repetitive. Wood preparation, cutting to dimensions, joinery, gluing etc. Because my machinery includes basic shop power tools, I think that every one of the jigs finds its place in a project.”

Just as a proud parent won’t select a favorite child, Niki actually uses most of his jigs while building his projects. “What’s my favorite jig? That’s a difficult question. I think that I use all of them in almost every project because most of the steps are very repetitive. Wood preparation, cutting to dimensions, joinery, gluing etc. Because my machinery includes basic shop power tools, I think that every one of the jigs finds its place in a project.”

Just as with any typical woodworker, Niki always has his eyes on buying the newest and flashiest tools. Until he can afford them, Niki is making the most of what he has. “I’m happy with the tools that I have…the jigs are multiplying the possibilities of every tool.”

You can see a collection of Niki’s jigs at the following forums (Be sure to search for the poster name Niki):

Hand-Cut Dovetails After Fifty

Wow, if this week’s quick poll is any indication, it looks as if the majority of our readers prefer to hand cut their dovetails. That’s quite a surprise to me.

Wow, if this week’s quick poll is any indication, it looks as if the majority of our readers prefer to hand cut their dovetails. That’s quite a surprise to me.

This site’s author Norman Havens proves you can teach an old dog new tricks. This site offers step-by-step instructions with clear photographic illustration of the hand-cut dovetail process – from the initial steps of marking out the pins to the final fitting of the completed joints.

The most valuable part of the site is that Havens not only describes the process, he also discusses the difficulties and mistakes he made along the way. This way, the novice dovetailer can hopefully avoid some common pitfalls.

While there are many other processes to cut these complicated joints, this site will get the novice up and running with the basics.

I’ll remember it like the day it happened. I was standing in Busch Gardens, the Dark Continent in Tampa one steamy August afternoon. Looking up, my sight fell upon the aqua and red tracks of Kumba, the new enormous roller coaster the park had just opened. 143 feet tall. 114 foot vertical loop. Batwing maneuvers. Not one, but TWO inverted cobra rolls. This thing was a monster.

I’ll remember it like the day it happened. I was standing in Busch Gardens, the Dark Continent in Tampa one steamy August afternoon. Looking up, my sight fell upon the aqua and red tracks of Kumba, the new enormous roller coaster the park had just opened. 143 feet tall. 114 foot vertical loop. Batwing maneuvers. Not one, but TWO inverted cobra rolls. This thing was a monster.

As the train whooshed by at 60 miles per hour, I could feel myself being knocked backward by the rush of air and deafened by the roar.

And, I was in line to take a ride on it.

I grew up in a family where my mom couldn’t stand to see her sons in peril. She cringed through six football seasons as my younger brother took to the gridiron. We grew up within short driving distance of a ski resort, but never went because it was too dangerous. Needless to say, whenever we went anywhere with a roller coaster, we were told just how perilous they were.

So, you could imagine my fear when I boarded the train – my first real roller coaster train – and it started to go up the lift hill.

Now, sure, it may not be as dramatic as that first rush down the hill in the coaster, but why do I sometimes feel the same apprehension before trying anything new when I woodwork?

For instance, a few years ago, I was building a shadow box for my dad to house his military badges and medals. I found some choice maple that would be perfect when finished. I also found a nice scrap of cherry molding that would be just long enough to dress the piece up and serve as a glass stop. Everything was going to be perfect.

For instance, a few years ago, I was building a shadow box for my dad to house his military badges and medals. I found some choice maple that would be perfect when finished. I also found a nice scrap of cherry molding that would be just long enough to dress the piece up and serve as a glass stop. Everything was going to be perfect.

In order to make this piece extra special, I decided I was going to use dovetails. My first ones. Ever. Gulp.

No one could accuse me of not doing my homework. I read everything I could get my hands on about machine vs. hand cut. I visited every woodworking forum I could think of. I asked every woodworker I knew for their opinion.

Finally, after nearly two months of weighing my options, I went to my local Woodcraft, walking with the swagger of a seasoned woodworking veteran, and headed straight to the dovetail jigs. When I got there, I froze. The choices were staggering. Akeda. Leigh. Shop Fox. Stots Template Master. I had that blank look in my face when one of the employees walked up and asked me what I was looking for.

When I told him I was a complete novice and never had even seen a dovetail jig before, he recommended the Keller setup. I plunked down my hard earned dead presidents and headed to the car.

When I got home, there was no bravado or swagger left. I found myself staring at the manual, trying to make heads or tails of what I was reading. Tentatively, I assembled the jig and put the bit in the collet. I laid the router down, wood clamped to the jig, and walked inside.

Six days later, when I finally got the courage up to actually make a cut into the lumber I had lovingly jointed, planed and cut to length, I gingerly stepped into the shop and plugged the router in. The router whined to life and, after stopping six or seven times to ensure everything was the way it had to be, I touched bit to wood and stared cutting. Sawdust flew everywhere. Cut, cut, cut.

When I was done, I flipped the jig around and cut the pins. Cut, cut, cut.

Much to my amazement, the joint slipped together – perfectly – on the first try. I was so jacked, I took the pieces inside and showed my wife, who happened to be taking a nap on the family room sofa.

“Wha… Oh, that’s great.” She closed her eyes and lay back down to sleep.

I walked back to the shop, and proceeded to cut the rest of the joints. That afternoon, I had met dovetails, and I had kicked their butts.

When I stepped off Kumba after my first ride, I was pumping my fist in the air.

Now, THAT’S what I’m talking about!

After that, I looked at all roller coasters with a sense of anticipation. “Honey, when can we go to Sandusky, Ohio to ride the coasters up there?” I want a new challenge.

Funny how that first success can breed so much confidence…

[poll id=”3″]

Wow! Sharpen your chisels and break out your hand saws! A large number of our readers prefer to cut their dovetails the old-fashioned way.

In my real job, I work in a busy communications office where we frequently hold meetings about important happenings. In our conference room, we have a laptop computer and an LCD projector. We can tie into the Internet, play PowerPoint presentations, show video etc.

But, yuck. The tangle of cables. The exposed computer. So, one day, my boss turned to me and asked, “Can you build us something?”

Does that qualify as something?

The design was one I had sketched up from scratch. It’s a mahogany box with a maple top hinged on. There’s a ‘garage’ where the computer can go in to hide, a hole in the bottom of the box for the power and internet connections and a cable hole for the data and power cords for the projector. I dovetailed the corner with the Keller dovetail jig.

The finish was a 1# cut of dewaxed shellac, buffed out with #0000 steel wool after it had cured for four hours. Then, I used two coats of Watco natural Danish Oil. After that cured, I waxed the piece with Minwax furniture wax. It’s not a table top, but it should stand up nicely to the rigors of long meetings.

Nice piece sez everyone.

And, if you have to work on the connections, the top lifts up for easy access to the works. This is a better set up than having a projector permanently mounted from the ceiling, because if we ever have to move the equipment to a new location, we can disconnect it and take it with us.

So, what about you? Do you have a project you want to brag on? Be sure to e-mail me if you want to share.

Sure, it sounds like a page where people might talk about gruesome murders or the latest shoot-em-up video game, but this is actually one of the best resources for Stanley hand plane information on the Internet.

Sure, it sounds like a page where people might talk about gruesome murders or the latest shoot-em-up video game, but this is actually one of the best resources for Stanley hand plane information on the Internet.

Patrick Leach of the Superior Tool Works assembled this virtual library of information on the hundreds of different styles of hand planes build by Stanley Tools from the mid 1800s through the 1960s.

Leach concentrates his efforts primarily on the Bailey and Bedrock offerings, not delving too deeply into the lesser-quality lines such as Handyman.

While his style is pretty tongue-in-cheek, and he does lean heavily toward offering his own personal opinions (especially when it comes to the transitional offerings from New Britain) there is no doubting that he has done his research. Sole lengths, blade widths, special features and the like are all offered in meticulous detail. If you are looking for a new hand plane, this site is a must see.