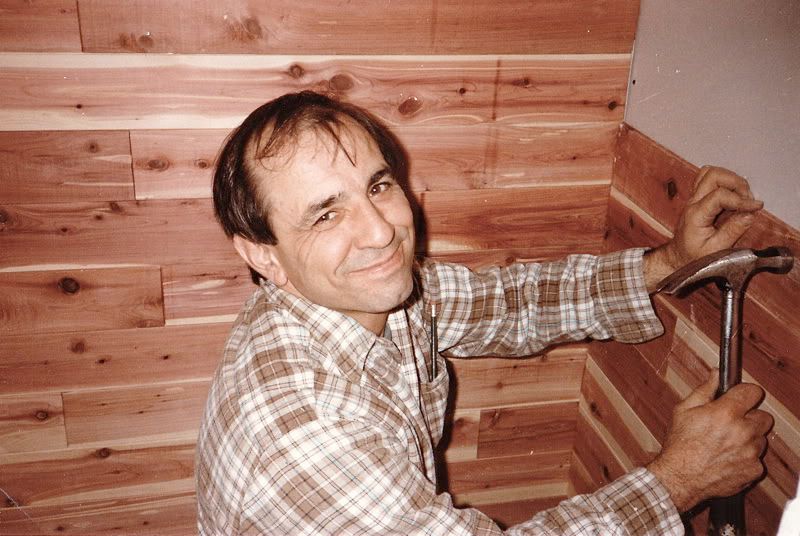

I have trouble getting things square.

There. I said it. I don’t have the ‘eye’ to get things square on just the first crack. Or, sometimes the second. Or even the third.

But, eventually I get things right. And, that’s due primarily to a lot of measuring aids that I turn to. I have a number of clamping squares that help get things at right angles during assemblies. And, then there is my little double square I like to pull out while I’m planing to ensure I’m not getting out of square while I true an edge.

But, the real multi-tool of them all is the combination square. That sucker is a real workhorse in most shops. It typically comes with a 12 inch rule and a head that measures 45 and 90 degree angles. There are other heads that can increase that versatility, including protractor heads and center-finding heads. You can check assemblies for square, measure bit or blade height above a table, use them to scribe a cut line … well, they are a tried-and-true multitasker in the shop.

You can go uber-cheap with them, picking up the big-box home improvement version, or you can drop some serious coin on a Starrett model. But, for the average woodworker who needs a great, reliable tool AND would like to have some money left over to buy some wood, there are some options available.

One that was sent to me by my new sponsor Bora Tools has an interesting feature I have never seen in a combination square. Most models use a ruler with a groove milled down the middle of one side. And, in the head, there is a nut that can be tightened down to lock the rule in place. The system works well, but if you ever pull the rule out to measure by itself, getting the parts all aligned can be a real pain in the posterior.

Bora’s combination square does away with all of that nonsense, relying instead on a set of rare-earth magnets to hold the rule in place. It holds securely enough to allow accurate measurements to be obtained, yet still allows for easy adjustment for changing measurements.

The rule that comes with this combination square is a substantial etched stainless model graduated coarsely on one side (in eighth-inch increments) and fine on the other (32nds). I have used this as a guide for my marking knife, and its thick edge is a sweet surface to reference the knife against.

The head of the tool is cast zinc, with all of the edges that contact the work surface milled well. It comes with a steel scribe for use when marking cut lines for joinery. And, it comes with the obligatory level vial to serve as a level or plumb reference.

When you throw in that Bora guarantees this tool for life, well, come on, what’s not to like?

Now, I just have to make sure I actually USE this thing when I woodwork, and stop trusting my poorly calibrated eyeballs.