I had a lousy weekend. No, nothing went wrong in the shop, and the wife and kids are all doing well. I just had some health ‘issues’ which needed to be resolved.

Since I’m here relaxing at the house, I realized that I have left you hanging on a few projects. Ones which I wrote articles about, but never showed you the final piece. Well, today I’m going to fix that.

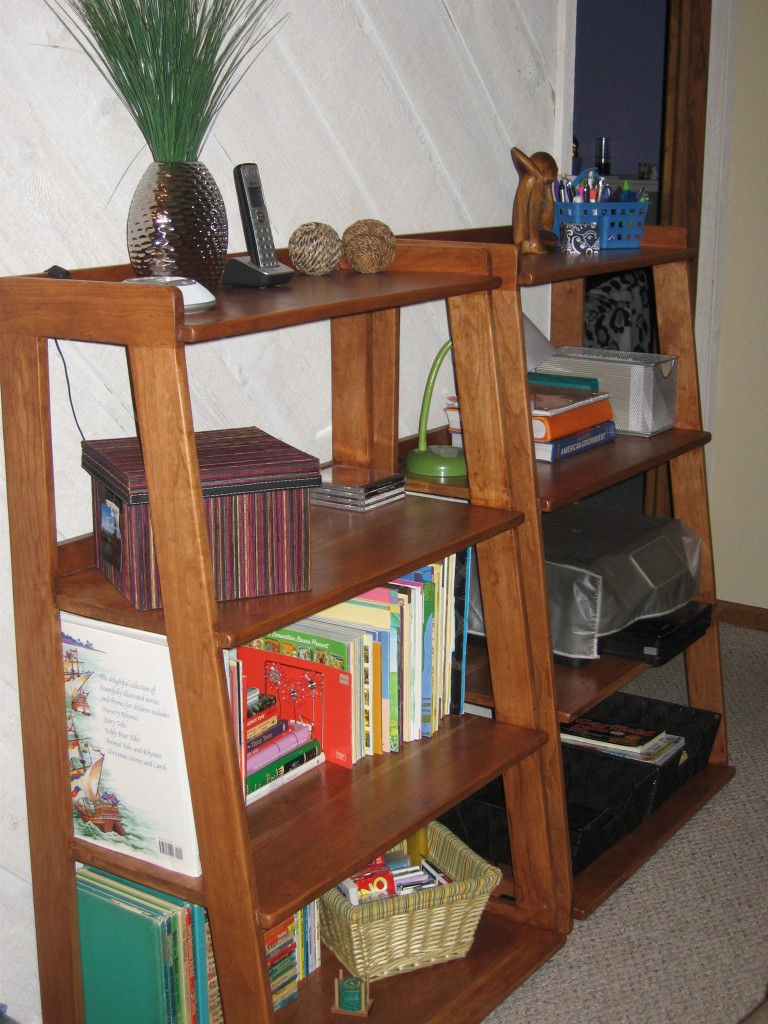

First, here are those stair-stepped bookshelves in place. As you can see, my friend Carla wasted no time getting them in to their final location and loading them up with goodies. I like the way you can look into the side of the cases to see what’s stored there, and she likes the width of the lower shelves for larger storage.

I do have to go to her house to install some leg levelers on the shelves. While they sit very stable on the carpet, one unit has a bit of a wobble on hard floors. Since they are planning on replacing the carpet one of these days, I figured it would be good customer service to head over there and install those potentially necessary pieces.

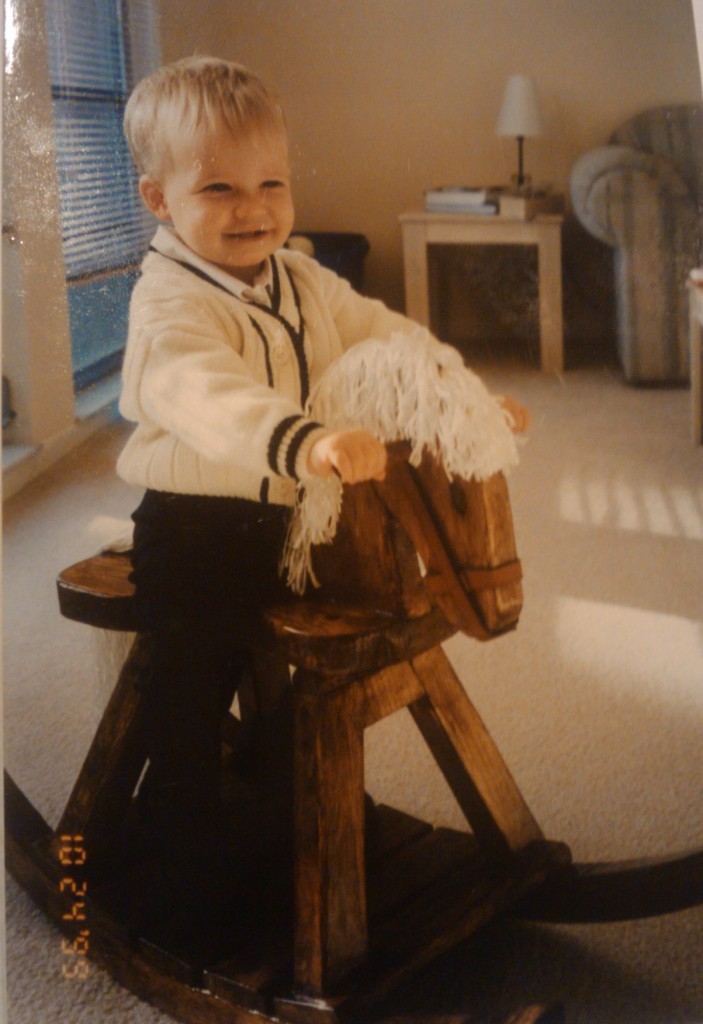

The other piece is the Munkstol. After I repaired the round tenons in the piece, I glued it all together with hide glue and replaced a few dowel pins which were holding the chair together. The challenge with this chair is that it is triangular, so getting good clamping pressure on the joints took a little bit of work and finesse. In fact, what I did was glue the front assembly together and clamped it until the glue cured, then clamped the other parts in place. It took some muscle and a few naughty words, but now it’s good to go.

Rhonda and I brought it to our neighbor’s home once it was done. Our neighbor was so happy, she took a picture and sent it back to the family in Sweden. Once that happened, gosh, the praise started coming in two languages! I’m glad that Google offers its free translation service… otherwise, I’d be sunk.

Now, I meant to finish the rocking horse over the weekend, but that plan went by the wayside. I’ll get that done this week (I hope) and then I have to move on to the next project.

Great weather. A busy shop. Fairly decent health. Hey, what else can you ask for?