Hey, everyone, it’s Iggy again. I really do like that guy Tom. No, seriously. But, when the tailless wonder went up to the Big Apple to help those people who were hit by Hurricane Sandy, SOMEONE had to keep the shop up and running… and it’s a good thing he had me to do the honors.

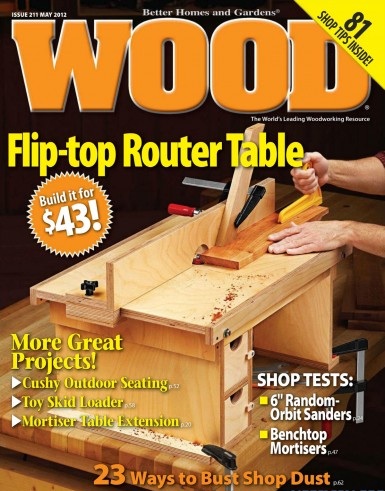

In addition to reorganizing the shop, whittling dovetails with a frozen herring and doing all other kinds of derring-do, I also had some time to sit down and pen a few words that the folks at Wood Magazine enjoyed. They enjoyed them so much, in fact, that they published them in the December/January 2012/2013 edition of the magazine under the title of Get what you really want this holiday.

Now, I’m sure it may sound mercenary at first – after all, we should be thankful for any gifts that we do receive during the holiday season. But, you would be amazed how difficult it is to shop for someone who woodworks! Many of the uninitiated out there may spend a tremendous amount of time scratching their heads wondering where to even begin looking for gifts for the woodworker in their lives, and usually end up picking up one of the old holiday standbys – a Reindeer sweater.

The article helps you guide the gift givers in your life to make shopping for you an easy process they will enjoy.

Which is more than I can say about having to work with Tom at times. I hear he may be looking for a Santa suit to wear while working in the shop. I’m not sure how he plans on keeping the wood chips out of his beard.