I just discovered that it was about four years ago when I left you hanging. Yeah, sorry about that.

Back in August of 2009, I wrote about my wood jumble. It was in an area of my shop where I stacked wood with little organization, which made finding a particular board for a project a nightmare.

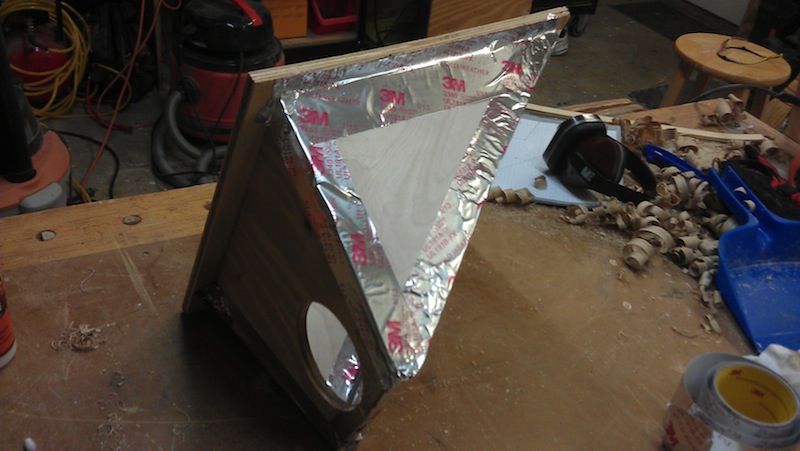

Fortunately, my wood storage has evolved to a little better arrangement. I found an area that was between my band saw and the standing storage tower that was open and would serve as a great place for some vertical storage for my boards.

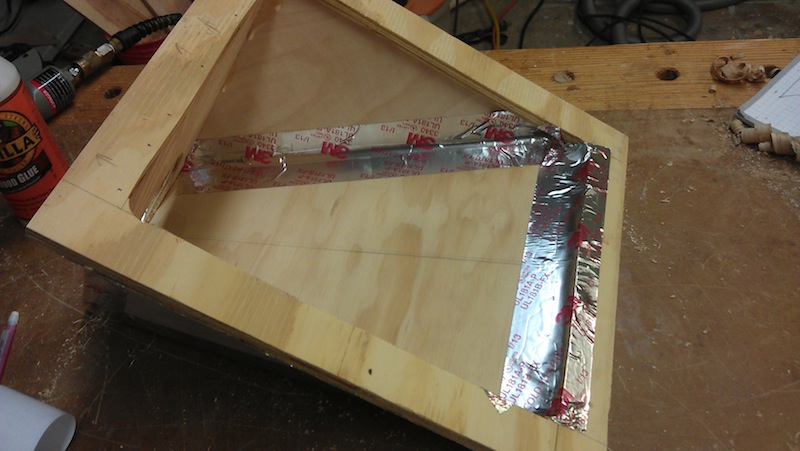

I spent this past weekend arranging the boards in my shop, creating this area to store all of my lumber. It was a pretty simple system, involving some Tapcon screws, a few 2 x 4 scraps that I picked up out of the scrap bin over at the local home improvement center and a few lengths of electric conduit. All I did was bore some holes into the 2 x 4s to hold the conduit, and then mounted those 2 x 4 cleats into the wall.

I put three lengths of conduit into each of the cleats, using these as dividers to help control the stacks of wood so they don’t flop around. It’s not the most perfect arrangement – the boards seem as if they can push on the conduit, levering the cleats from the wall. I may have to go back to the drawing board on that one…

I put three lengths of conduit into each of the cleats, using these as dividers to help control the stacks of wood so they don’t flop around. It’s not the most perfect arrangement – the boards seem as if they can push on the conduit, levering the cleats from the wall. I may have to go back to the drawing board on that one…

Anyway, i was able to get the boards in there. Now, when I need to reach for a board, there’s no issue with finding my choice boards. I simply can look into there and find the rough or previously-milled pieces of wood to find the one I want for a new project.

Dang, I have a lot of boards in there… Maybe I should build a few new projects!

Dang, I have a lot of boards in there… Maybe I should build a few new projects!