Curves. Resawing. Joinery.

The band saw is one of those tools you wonder if you need at first, but wonder how you got along without after you have used one.

“Band saws are amazing tools,” said Dan Walter of Eagle America. “When set up and properly tuned, even the most basic of band saws can improve your woodworking capabilities. Slice your own book matched veneers. Make elegant band sawn boxes. Heck, you can even cut hand cut dovetails without touching a hand saw simply by using your band saw.”

The band saw works by – as you might imagine – pulling a narrow band of steel with saw teeth cut into the edge through the saw’s table. The energy for the cutting is provided by one powered wheel, with a second idler wheel on the top of the saw that keeps the band spread and helps it track. “The size of the saw is based on the diameter of each of these two wheels. So, a 14″ saw has two wheels 14″ in diameter… and, no, it doesn’t take a 14″ long blade…”

Band saw blades are exceptionally thin under some tremendous pressure, so the steel has to be both flexible and strong. It also has to have hard teeth in order to slice through wood with little trouble. “It’s a delicate balancing act for saw blade manufacturers, and it takes a lot of thought to get things to work just right.” Dan explained to me that Eagle carries the Olson line of bandsaw blades. The standard Flex-Back models are a great value general-purpose blade, and the All-Pro blades have additional elements added to them to make a harder steel that gives more durability while still maintaining flexibility.

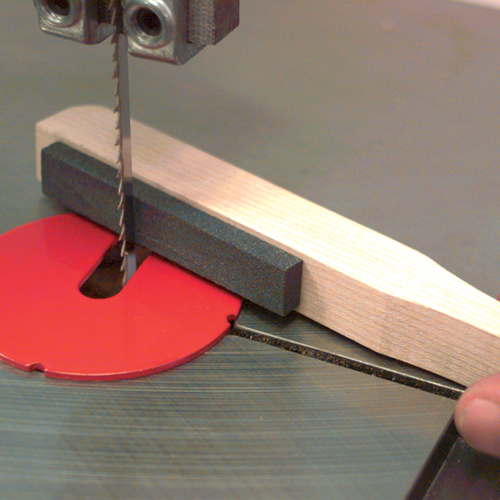

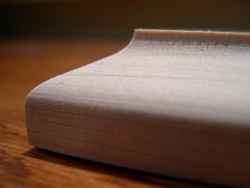

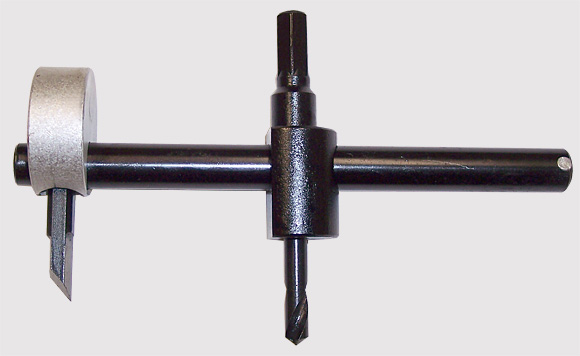

Because the blades are cut and then welded together, there’s a chance that a rough weld could give you a rougher cut. And, curves are easier if the back square corners of the blade are rounded slightly. Eagle sells a special band saw blade stone that can be held against the back corners of the running blade to smooth things out, or a standard whet stone can be used as well. And, once the blade is polished with smooth back corners, a blade lubricant can help improve the quality of your cut.

What those blades ride on are the wheels – and the tires that cover the wheels. “Tires are so often overlooked on band saws, but they play a major role in how true a blade will track. Rubber tires can crack and wear over time, and urethane tires give a better ride for the blades. If you have trouble with your blade tracking true, you might want to check the condition of those tires and replace them if needed.”

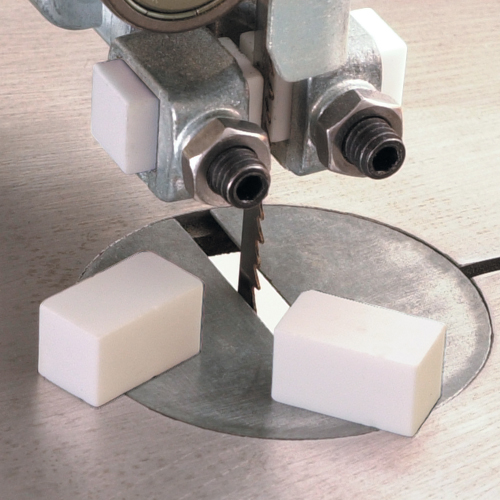

The blade on most band saws is guided both above and below the table. They help keep the blade running true and prevent unnecessary twisting as the cut is being made. “Your standard-issue blade guides in most saws are metal blocks that help to contain blade movement. They are adequate, but they tend to create a lot of heat as the blade rides through. To help extend the life of your blades, you might want to consider something like Cool Blocks that deposit a dry lubricant on the blade as it brushes against them, or upgrade to ceramic blocks which also reduce friction heat build up and can ride very close to the blade.” Dan pointed out that even a standard set of blade guides can be replaced with a product called Band Rollers, which use bearings to guide the blade, meaning that the guides can touch the blade body with no chance of heat build up.

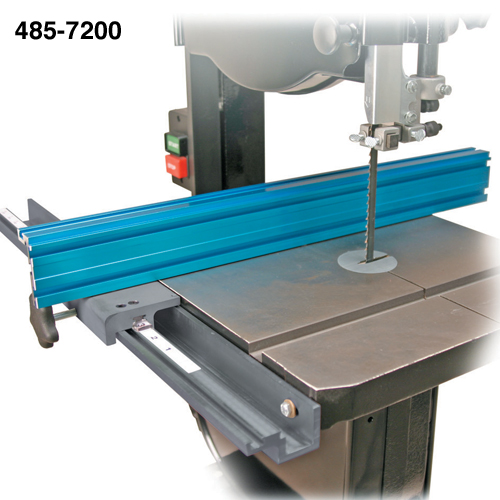

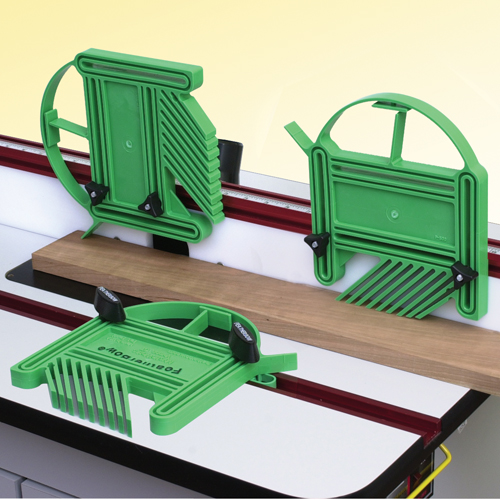

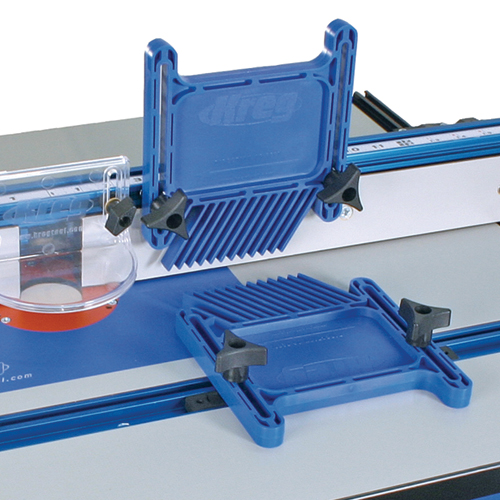

In order to reduce costs, many manufacturers don’t include a fence in most entry-level band saws. To overcome this, you can build your own fence system, clamp a flat, straight piece of wood to the table or you can purchase an aftermarket fence system like the Kreg precision band saw fence with an optional micro-adjust feature and a resaw guide to make working safer and more accurate.

“The three most important things about the band saw – or any tool for that matter – are to assemble and prepare it right when you set it up, understand the best ways to work with it and to maintain it properly. If you take care of your band saw, it will serve you well for years to come.”