Back when I was in middle school, my dad approached me one day. “Son,” he said, “when you go to shop class tomorrow, ask your shop teacher if he has any literature on raised panel doors.”

Back when I was in middle school, my dad approached me one day. “Son,” he said, “when you go to shop class tomorrow, ask your shop teacher if he has any literature on raised panel doors.”

This struck me as funny because 1) I wondered why Shakespeare or Dickens would be writing about raised panel doors, and 2) How would the guy teaching me how to build a coat rack know how to build raised panel doors? Undeterred, I went to school the next day, worked through the hour long shop class and totally forgot to ask my shop teacher about how to build raised panel doors. Remember, that’s how the 13 year old brain works… I see that from time to time in my oldest son.

What my dad needed was something a little more – uhhh – available to him when he needed the information. Oh, sure, our library had books about woodworking, but its hours were limited, and my dad worked late. No, what he needed was… TA DA… the Internet.

It’s stunning to see how much the Internet has changed things since I first got into the craft back in 1999. Yes, there was an internet back then, and yes, there was information about woodworking on it. Compared to today, why, it was just a drop in the bucket.

If my dad had access to the internet today, he could not only found out about how to make raised panel doors, he could have also learned how to build a TV cabinet, stud a wall or lay carpet– all tasks we tackled in the basement remodel at our house.

He could have even learned techniques to help his teenage son remember things.

The beauty about being a novice woodworker today is that there are thousands of sites out there, each available to teach you about the craft. Are you interested in turning? Marquetry? Chair Making? Building kitchen cabinets? It’s all out there on the web.

Point is that it’s never been a better time to be a new woodworker. Your internet connection can put you in touch with tool manufacturers, hardwood suppliers, other woodworkers who want to lend a hand… it’s all out there. Take advantage of the opportunities and get into the game.

And, to think, you don’t have to rely on a forgetful teen to remember to find information on how to do things.

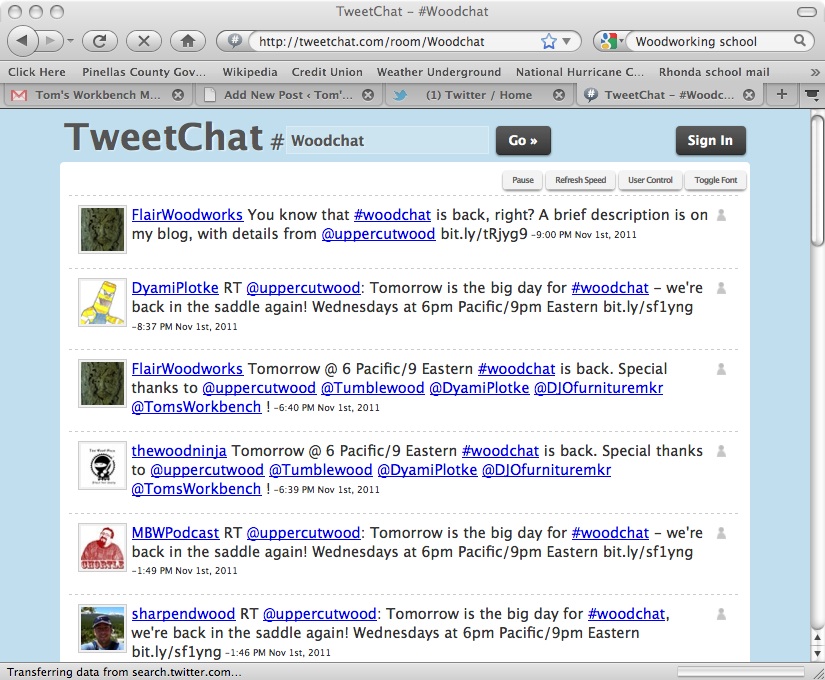

For those of you who have Twitter accounts… check this out. Tonight at 9 p.m Eastern (that’s 2 a.m. on Thursday in Timbuktu), I’m going to be on WoodChat discussing Get Woodworking Week. If you would like to participate, sign in to your Twitter account, then follow this link to TweetChat. There, you can ask questions about why this week is happening and get further inspiration. Hope to see you there!

The links for Get Woodworking Week keep on coming… and, they are awesome! Here are a few more…

- The Village Carpenter: Just do it!

- The Renaissance Woodworker: Get Woodworking… NOW!

- Wood Magazine: Beginner techniques

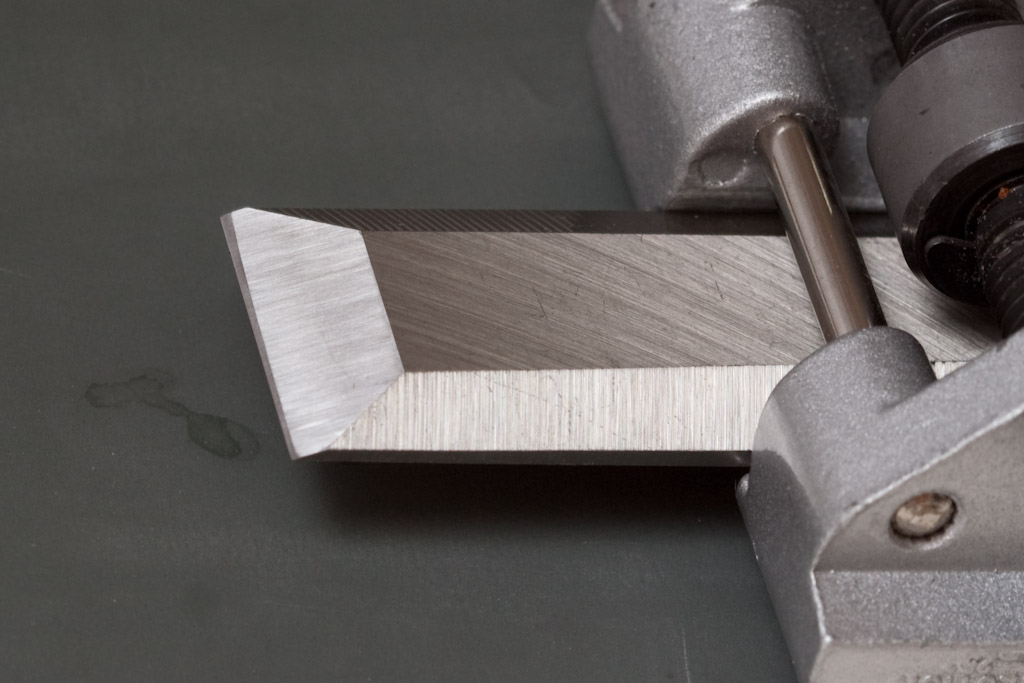

- The Sharpening Blog: Basic Sharpening Notes

- Hardwood to go: Tips for buying lumber for your next project

- Giant Cypress Blog: The Shellac redemption

- Woodcanuck’s Blog: So you want to be a woodworker?

- Wood Chuck’s Workshop: Shellac, this beginner’s favorite finish

- Brownell Furniture: Getting Found Online

- Bucks County Craftsmaster’s Blog: Football is over. So, now what?

- Might as well dance: Woodworking: where to begin?

- The Wood Lab: Don’t let shop ‘shortcomings’ stop you!