Yesterday was Valentine’s Day… Which meant that I had better come up with a gift or face the wrath of my sweet beloved…

Just kidding, Dear.

Just kidding, Dear.

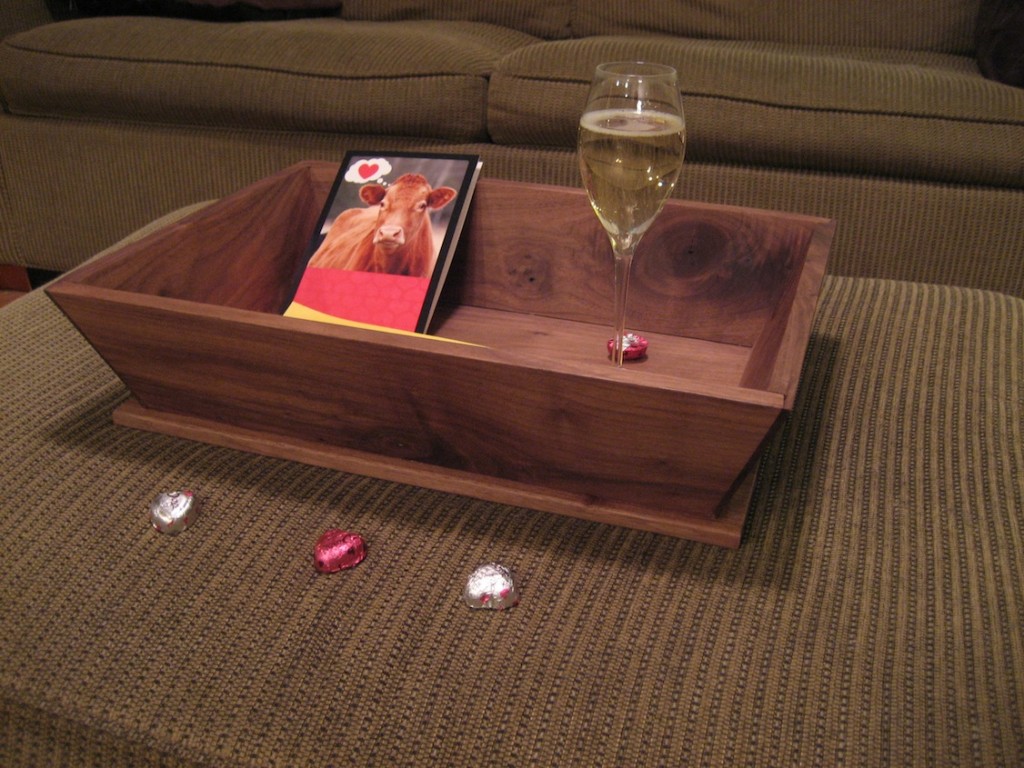

Actually, my long-suffering wife had once mentioned something about our living room. There, we have our couches, a few side tables, the TV, a built in entertainment center and an ottoman. A nice big one that two people can sit on, or you can throw your feet up on after a hard day of work. The only problem? No coffee table. No place to put a drink down, especially when you are sitting at the end of the love seat farthest from the end table. “Wouldn’t it be great if we had some kind of serving tray to put on there?”

Of course, she said this about three years ago… but, who’s counting? With the hanging wall cabinet done, my shop was kinda quiet, so I put my mind to building a serving tray. Which plans to use?

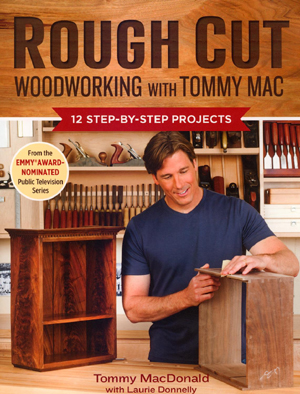

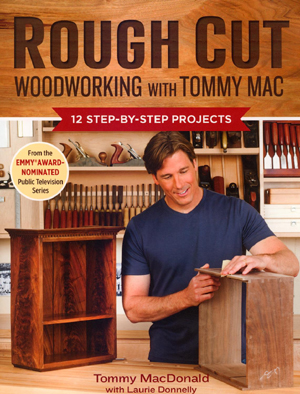

It turns out that the folks who published Tommy Mac’s Rough Cut Season One companion book had sent me a copy to evaluate. And, there was a plan in there for a serving tray.

Digging around in my wood pile, I found a 8/4 chunk of walnut. Rhonda had mentioned that she liked the way the wood looked during the wall cabinet build, so I figured that would be the piece to grab. With my band saw now able to forgive me after the years of abuse I had heaped upon it, I rigged it with my 5/8″ resaw blade and proceeded to resaw the piece into three separate pieces. Working with my new thickness planer, I was able to get the pieces looking sweet in very short order.

In fact, I think I fell in love with resawing… I may need to do a whole lot more of that!

Following the instructions in the book, I was able to glue up the bottom and cut the sides and ends out of the plans I cut from the board. The tip in there about building a ‘magic block’ to help set the compound miter cuts was killer, and I got everything right on the first try. I cut rabbets on the ends pieces to accept the sides, and my boys came out into the shop to help with glue up and assembly.

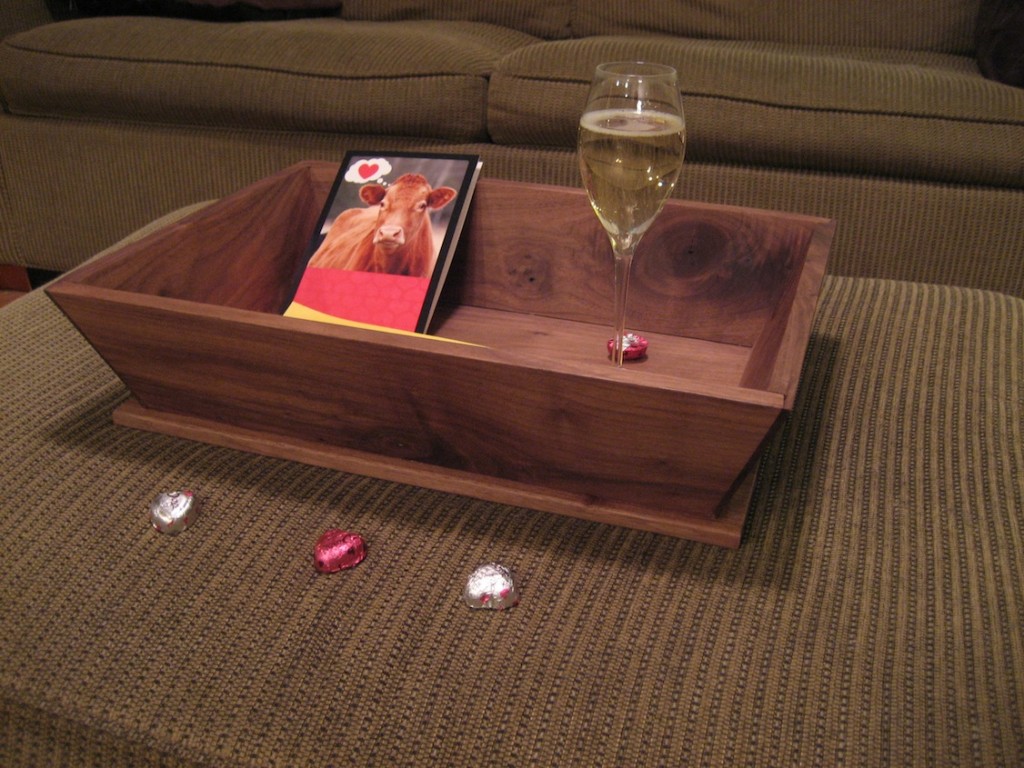

Unlike Tommy Mac’s version, I used brad nails, filling them with some dark wood putty. I had the boys sand the piece, and finish it with a coat of shellac. After smoothing the finish with some 320 grit paper, I rubbed in three coats of Johnson’s paste wax to get a soft, touchable feel to it.

After Rhonda left for work, the boys and I staged the tray on the ottoman with some special chocolates and cards from each of us. And, it was my youngest son Steven who got to surprise Rhonda with the piece when they returned from school yesterday afternoon. How sweet…

So, you wanna hear a review about the book? Funny you should ask… The Modern Woodworkers Association – more specifically, myself, Dyami Plotke, Chris Adkins and Michael Lingenfelter – got together to do a review of it. Here’s the audio review for your listening pleasure…

Be on the lookout for more stuff from the Modern Woodworkers Association coming soon!