I don’t know if you heard, but last week, I went over to the Kennedy Space Center on Thursday to catch the launch of the brand-spakin’-new Orion crew module. And, if you followed the news, you probably saw that it was scrubbed. Bummer, because the family and I headed over from our home here in the Tampa Bay area at midnight to get there at 2:30 a.m. … and the sucker didn’t launch. And, we had to drive the two and a half hours back home – on very little sleep – and pretty disappointed.

But, the next day, that sucker headed to the skies on the first attempt. The launch of this new capsule marked the start of a new era in space exploration.

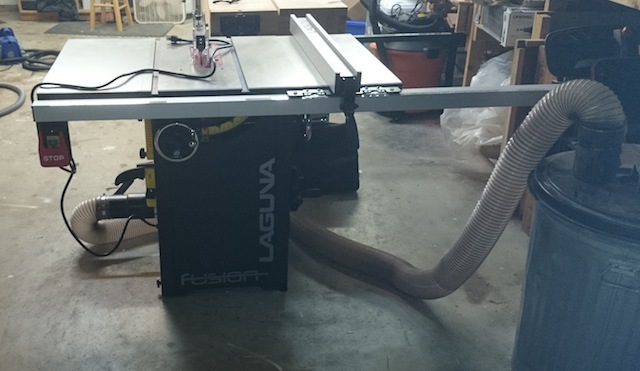

Surprisingly, the same day Orion left the launch pad, a new piece of technology arrived at my shop, shipped in a large crate and a smaller box shrink wrapped to a pallet. It you bet, it was my new Laguna Fusion saw. I broke away the packing like a man possessed, trying to get to the new saw contained within. I almost felt a little like the dad in the movie A Christmas Story, attempting to get to his major award…

There, contained within a very well packed case was my brand new Laguna table saw. It was gorgeous, with that beautiful Laguna logo on it. But, it obviously still needed a little bit of assembly before it was ready for prime time.

Early on Saturday morning, I set out to make the new saw a reality. While I was attaching the wings and rails, the new owner of my old Ridgid saw showed up to pick up his new-to-him saw. It took a little bit of muscle to get to the old Ridgid onto his pick up truck, but I waved goodbye to my old friend as it rode off to its new home.

The new saw set up beautifully, but there were a few ‘issues’ I had to deal with. First, while there were awesome brackets to hold the rip fence, there was no place to hold the miter gauge on the saw that I could see. So, I used a pair of Magswitch magnets to make a bit of a landing area for the miter gauge on the saw. They worked well, and I didn’t have to do any drilling.

The other issue I noticed was that while the saw does come with a pair of casters, they are kind of difficult to use on a regular basis – they are more for moving the saw out of the way on occasion to get behind it to do some sweeping. I tend to move my saw around a lot, which means I need to think of a better solution. Also, the saw is about an inch and a half too low for my bench, which can present a problem for me. Right now, one of those sweet HTC mobile bases looks like the right solution.

Outside of those two small quibbles, this saw is a dream. It cuts beautifully. It’s much more quiet than my old saw. It is built like a tank. Its fit and finish is second to none. It doesn’t allow for any dust to get out into the shop. The large paddle stop switch is very convenient.

Outside of those two small quibbles, this saw is a dream. It cuts beautifully. It’s much more quiet than my old saw. It is built like a tank. Its fit and finish is second to none. It doesn’t allow for any dust to get out into the shop. The large paddle stop switch is very convenient.

And, it just looks awesome!

I am looking forward to this new era of table saw cutting in my shop.