This past weekend, I found out that a woodworker had passed away.

No, it wasn’t met with the nationwide attention of the passing of Sam Maloof or James Krenov, but it marked the loss of a very talented woodworker.

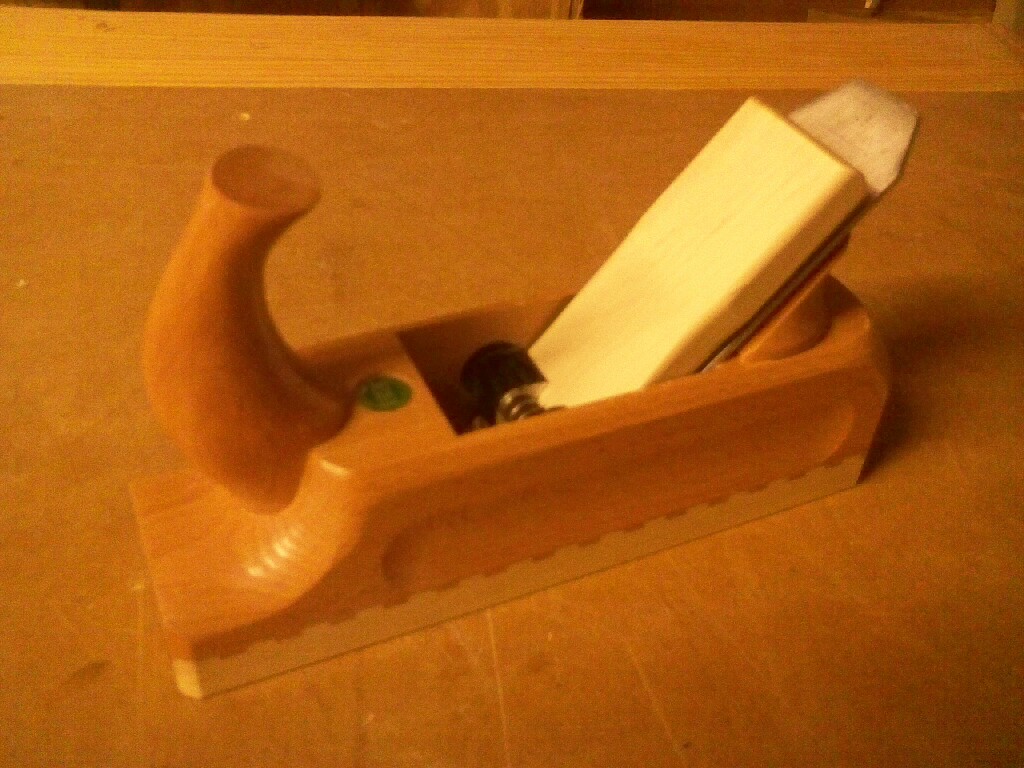

Early on in my time writing Tom’s Workbench, I was thoroughly impressed by the posts on the Woodworkers Website Association by Niki Avrahami, a woodworker who lived in Poland. When faced with a woodworking problem, Niki would build a jig. Not any kind of jig, but a jig that would just blow your mind when you saw it.

Elegant. Thoroughly thought out. Built with common materials. Bordering on genius.

Take this table saw sled Niki designed. Just this one plan has 40 large annotated photos showing how to unpack and use the saw jig he had designed in an earlier post. Clear, easy-to-follow instructions that anyone can follow. They show from the first steps of setting it up, how it’s used, the results of the cutting and – as with all of the posts Niki wrote – a ‘Thank You.’

Niki’s work was so innovative, he submitted several plans to woodworking magazines – and many of those were awarded as top tips. He posted his how-to’s on woodworking forums in Australia, Europe and North America. Thousands of woodworkers have been inspired by his creations.

While I interviewed Niki, I kept asking him, “Why don’t you write a book with these jig designs? It would be a top seller.”

And, every time I asked him, he always responded, “If I wrote a book, who would do my woodworking?”

Fortunately for us, Niki had left his plans and designs scattered across the Internet for others to read, learn from and build. Unfortunately, this got me thinking that there are many other woodworkers who do pass on and don’t leave a legacy of their knowledge for anyone. A few projects, some well worn tools and that’s it. All of the years of experience and know-how taken with them, removed from play forever.

In today’s world, many segments of knowledge are being lost to the ages. Master woodworker Toshio Odate spoke sadly about his friends who forge high-quality Japanese steel into chisels and plane irons. These elderly gentlemen in generations past would have shared their trade secrets with their sons, continuing the line of knowledge. Today, many of their children and grandchildren go on to high-paying office jobs rather than sweat at the forge. When those old men go, that very well might mean the end of superior-quality hand-forged Japanese steel.

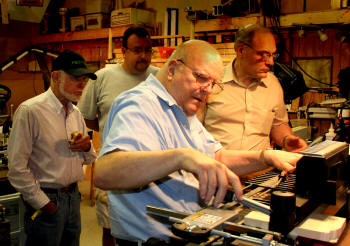

Thinking back on Niki’s passing this weekend, I think it’s critical that I ask each of you to do one favor for the entire woodworking community. No, you don’t have to start a website or draft a manuscript for a woodworking book. What I would propose that each of us do is to seek out an up-and-coming woodworker. A granddaughter or grandson. A neighbor. A Boy or Girl Scout troop. Invite them into your shop to watch you work and learn from you.

You might be the one to inspire a future woodworker.. and to ensure that your hard-learned knowledge continues well beyond your years.

Rest in peace, Niki.