No, it doesn’t have the gorgeous grain and strength of premium hardwood.

Nor does it have the beautiful veneers and screw holding capacity of cabinet grade plywood.

It doesn’t even have the smooth, fine texture of MDF that makes painting easy.

Instead, it forms the basis of all uber-cheap, mass produced big box discount store ready to assemble furniture. It’s frequently covered in a pseudo-wood-looking plastic contact paper like substance and is assembled with cams, dowels and other bizarre hardware that requires an allen wrench.

Attempting to lift a sheet of it by yourself can cause you to make an appointment with your chiropractor. Shelves made of it bow with the lightest of weight and sides exposed to the smallest quantity of water swell like a sponge.

Yes, it’s particle board, and it’s the most beautiful substance you can have in your shop.

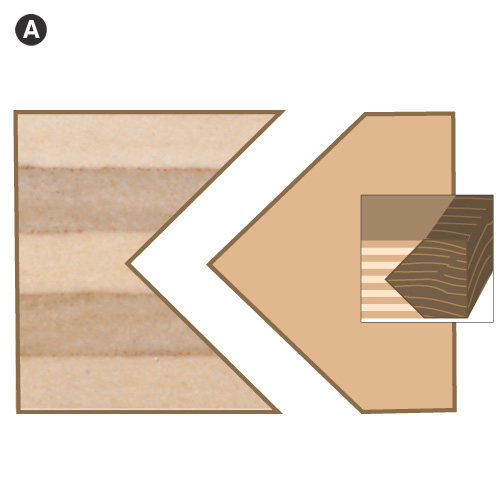

Born of the refuse of lumber mills, the lowly particle board (or chip board) consists of fairly rough sawdust treated with a resins, waxes and other goodies and heat pressed into standard sized sheet goods.

During the construction of this large cabinet project, I have come to appreciate some of the finer qualities of this oft maligned material. No, the boxes themselves are being made out of some high quality 3/4″ plywood – either prefinished birch or A-faced cherry. The cabinet shelves will be made of the same materials as well. The base the cases are standing on is made from 2×4 fir lumber.

So, where’s the particleboard?

Glad you asked. A while ago, I had bought a sheet of particleboard to create a bending form for my Mars and Venus Rising table. I was going to stack and cut pieces and use them to clamp the thinly sliced ash and walnut leg pieces around while the hide glue dried. However, I was having trouble getting the pieces to work on the press and opted for a different method of bending.

So, I took the sheets of particleboard and hid them behind my clamp rack. I probably figured I would find them three or four years later and just throw them out.

The fates were on my side when the project started. Those ugly, edge-abused sheets hidden behind the clamp rack called to me. With my old big ugly bench, I would have just cut the sheets up on the bench top, figuring that any grooves that formed on the bench would have added character. But, with my current bench, that was out of the question. No way was I going to slice up my new bench’s top.

That’s when I fished those sheets of particleboard from behind the clamp rack and set them down on the bench as a sacrificial top. My friend Paul was a little caught off guard by my wanton disregard for the particle board’s safety, but I forged on. In fact, after the cutting, it also served well as a sacrificial base when I predrilled the screw holes to reinforce the dadoes and rabbets, saving my bench tremendous abuse.

Today, the cabinet pieces are cut, the particle board pieces are showing the wear and my bench top has never looked so good.

So, today, I ask, dear friends, that each of you reconsider your opinion of the lowly particle board sheet. Truly, it’s not the material of fine woodworking, but I boldly contend that it is one of the substances that makes fine woodworking possible.