So, what have I been up to?

I know you really hate when I start my posts with that, especially when it’s not followed by details on a trip to a hardwood store, a woodworking school or my shop. And, you are about to hate this one as well.

Again, my day job is trumping the woodworking thing. Because I work in the realm of emergency management, I have been hard at work on two major events.

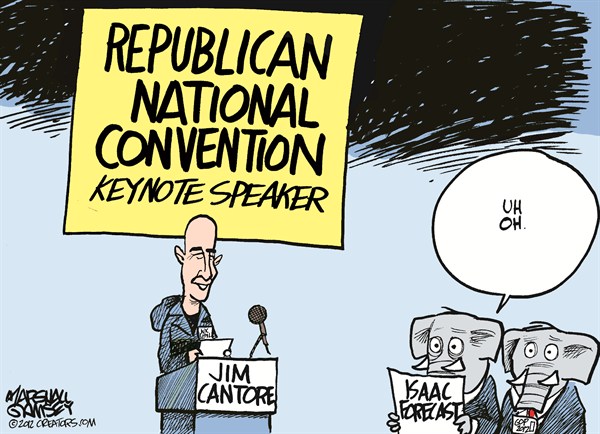

First, the Republican National Convention is coming to town. OK, maybe not our town, but the town just a little bit down the road in Tampa. Just a short eighteen months ago, the Republican party awarded the big party to Tampa, and since then, we have been working hard on planning for the big event. Training classes. Meetings. Functional exercises. I have met people from all types of government organizations. And, I’m working long nights to help ensure that if anything happens, we’ll be ready to respond.

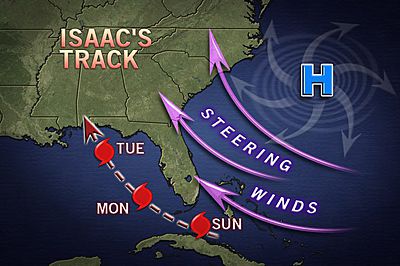

One of the things we were concerned about during the planning was the possibility of tropical weather. As if on cue, Tropical Storm Isaac has been threatening Florida and the Tampa Bay area. So, we shifted from the RNC planning to the important business of life safety, sitting in on conference calls with the National Weather Service and local emergency managers. Fortunately for us, it seems as if the storm has passed. Unfortunately for our friends in the northern Gulf of Mexico, it’s coming your way. Batten down the hatches.

Yeah, it’s been busy.

So, when things get stressful, what do I think about? My family, of course.

My bathroom project, which I did manage to finish grouting and caulking during my down time. Maybe I can get some work in on the walls while waiting for my next shift…

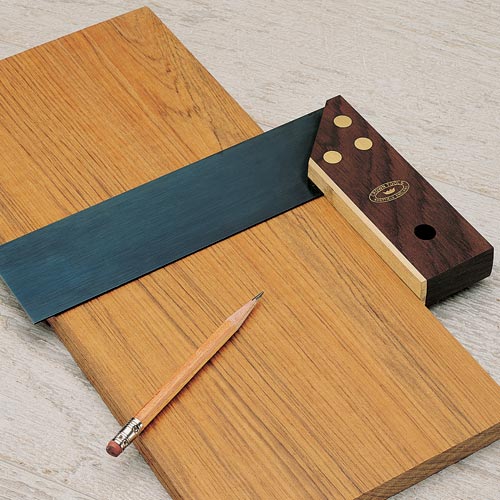

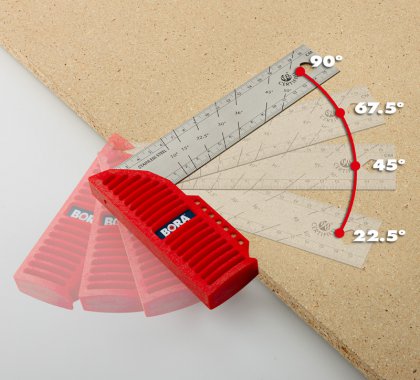

And my shop.

Yes, my little oasis of enjoyment, where, right now I have a pair of projects underway. One just needs to be finished, while the other one is in need of some joinery and the preparation of a few decorative panels. Pieces have been left as they were before I went of to instruct at the Emergency Management Institute, waiting for me to get back to them.

Since I am working nights, I may try to squeeze in a little time during the days. Heck, even if I just clean up the , that would be a step in the right direction! And, when I sit in long meetings about what’s happening, it doesn’t hurt to doodle out a few ideas… maybe for upcoming holiday gifts.

There is nothing like multitasking.