Wow. I just mean wow. With my deployment to New York, a bunch of things to do around the house, the Modern Woodworkers Association, the Wooodworkers guild, gosh, it seems like the holidays are racing up behind me, ready to capture both me and Iggy…

That’s why we are both working like crazy to get some stuff done. The manger for the nativity sets are done, so they are off the list.

Next up, I have to finish the hope chest for my niece. To refresh your memory, I have four nieces, and I am building a hope chest for each of them for their 16th birthday. My eldest niece, Carolina, got hers a few years back, and now it’s time for my niece Lauren’s. Her birthday was in mid-November, so – as you can imagine – this one is already late.

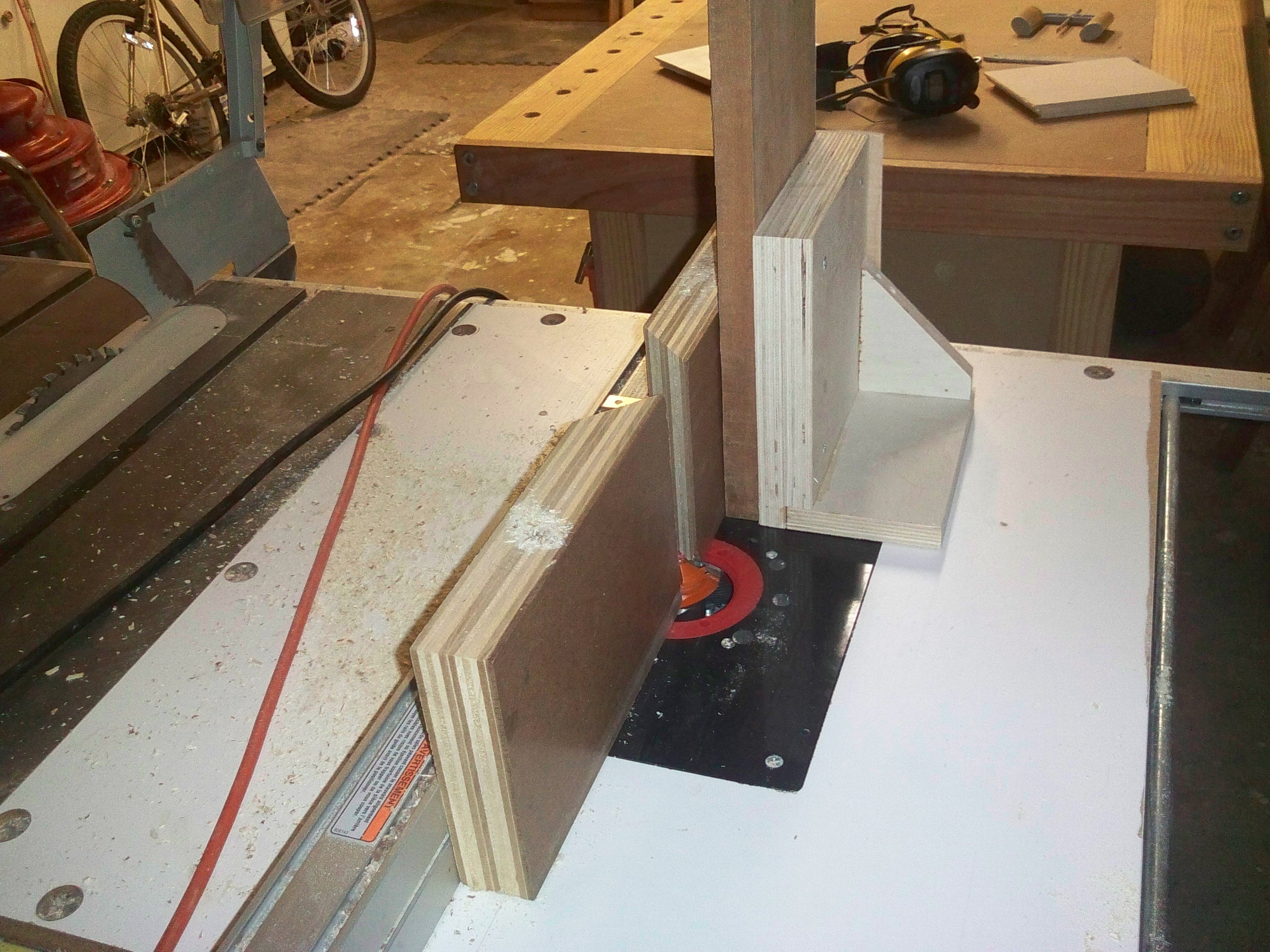

I needed it to be able to be packed flat for shipping up to where she lives, so I opted for frame and panel construction. Basically, this baby will pack into a top, two sides, a front, a back and a bottom. My brother-in-law is a pretty handy dude, so he can glue them together when he receives it. The piece is looking good so far, made of maple and Mayan walnut.

I’m particularly proud of how well the lid is coming out. I made the main part of it maple, and made the breadboard ends out of Mayan Walnut. I attached them by cutting a groove in the edges and a tongue on each end of the lid, boring some pins for dowels, enlarging the outside two dowel holes in the tongue and then gluing the middle into place before driving the dowels home. I like the look of the exposed tongue on the edges, and the contrasting dowels.

I will leave clear instructions for how the piece goes together.. she should like it!

I also have some pieces for a project I wanted to build for someone special in my family. I veneered a few beautiful pieces onto an MDF substrate using hot hide glue, but haven’t really gotten into production yet. I don’t want to tell you who it’s for or what it’s going to be, but I can tell you, I’m excited about this piece.

And, I know that at some time during the next few weeks, I’m going to have to start thinking about building something for the upcoming art show held at the county courthouse. I’m thinking of a safe project I can bang out in a few hours, and a more advanced piece that may take longer… I’m still sketching out a few ideas.

But, there are only so many hours in a day, and so many days before Christmas. I guess I had also better plan in some time to spend with my family to just relax and enjoy the season…

I wish for each of you to find some peace and quiet with the ones you love during this hectic season. Oh, and some enjoyable shop time!