So, I have this friend Kevin. He and I were both instructors up in Emmitsburg, Maryland last year at the Emergency Management Institute. Over the past year, we have stayed in touch, using Facebook, e-mail and other methods. And, over that time, we have talked about our careers and our families.

One thing I discovered is that his daughter is quite the gifted swimmer. In fact, she continues to push records for her age group, and she is racking up quite the collection of ribbons, trophies and medals.

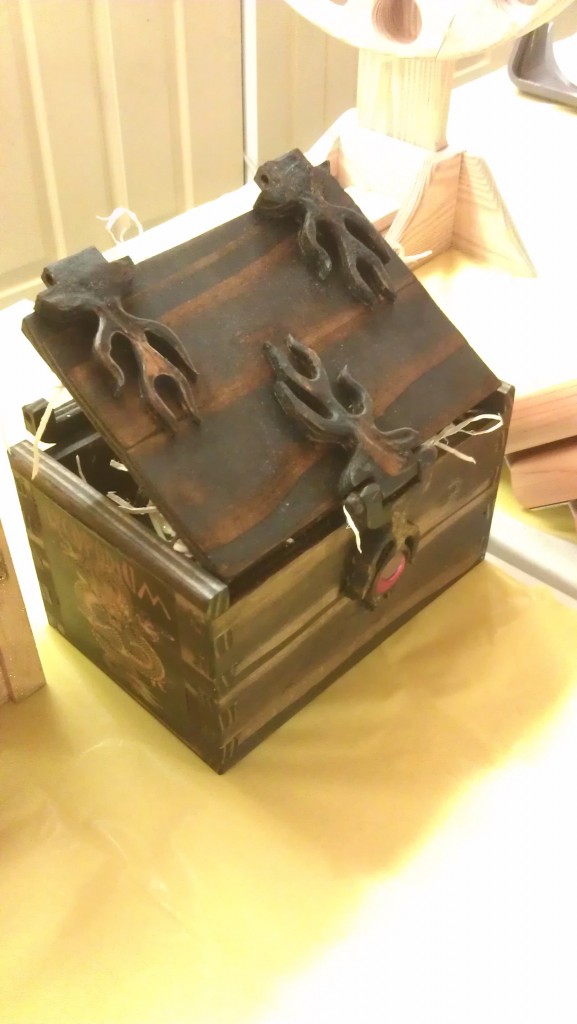

Which means, of course, she needs someplace to display these things. Now, I think this could be an awesome project to undertake. In fact, I am sketching out a wall-hanging design that will have space above and below for the medals and ribbons, and some shelves for the trophies in the middle. Yes, this is how I ‘SketchUp’ my projects…

OK, it’s kinda rough, but that’s OK. You can see my trophy at the top. The ribbons at the bottom are hanging from a rod supported between the two sides. Pretty easy design.

The only problem, Kevin lives in Yuma, Arizona. Yeah. About as dry as it is humid here in the Tampa Bay area. It’s a place I hear that ice cubes will evaporate even when in your freezer…

This means that more than ever I am going to have to plan for changes in humidity in the wood I will be working with. As you may recall from a wood movement experiment I conducted a few years ago, the results were pretty striking.

I am going to have to find a species of wood that won’t move a lot with the changes. And, whatever that wood may be, I will be looking for some quarter sawn boards to help reduce the propensity to contract once the wood hits its new environment.

And, of course, I will have to do a careful job of finishing to reduce the speed of the moisture exchange between the environment and the wood in the project. I will even have Kevin buy the glass for the front of the case after it has had a chance to acclimate.

Now, let’s see what we come up with.