July 2005

Before our neighbors had their daughter and son, they had a very cool all-glass dining room table. A glass top and two pedestals each made of 12″ wide glass strips joined at a 90 degree angle with two screwed together brackets. It was stylish. It was striking.

And, after they had kids, and those kids started to walk, they discovered just how unstable it was. In fact, after one energetic evening of their son and daughter running near the table, our neighbors ended up holding the heavy table top once a little one slid into one of the table bases.

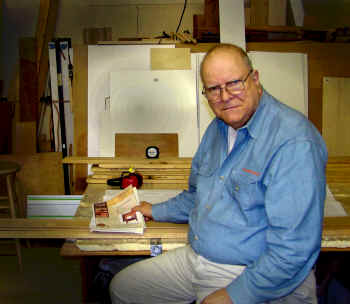

To help get the dining table issue under control, they asked if I could build a sturdy wooden base for the glass table top. Something that would be a little heavier, a little wider and a whole lot more stable.

Since the husband of this couple was born in Japan, I thought I would go with an Asian-looking trestle table base. Something a little more graceful, something a little more muscular and something out of maple.

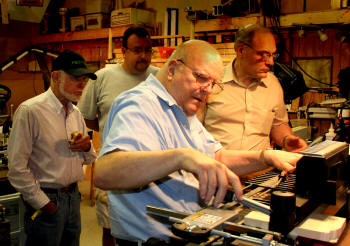

I built a pair of trestles starting with a massive base built up from three strips of maple. The middle strip was cut and glued into the sandwich allowing spaces to make ready-made mortises. The same process was done for the top trestle. Rather than build the upright support in the traditional manner, I glued two uprights into place, using the space between them as a mortise to receive the crosspiece. The uprights are glued and through doweled into the trestle base and bracket to ensure they don’t go anywhere.

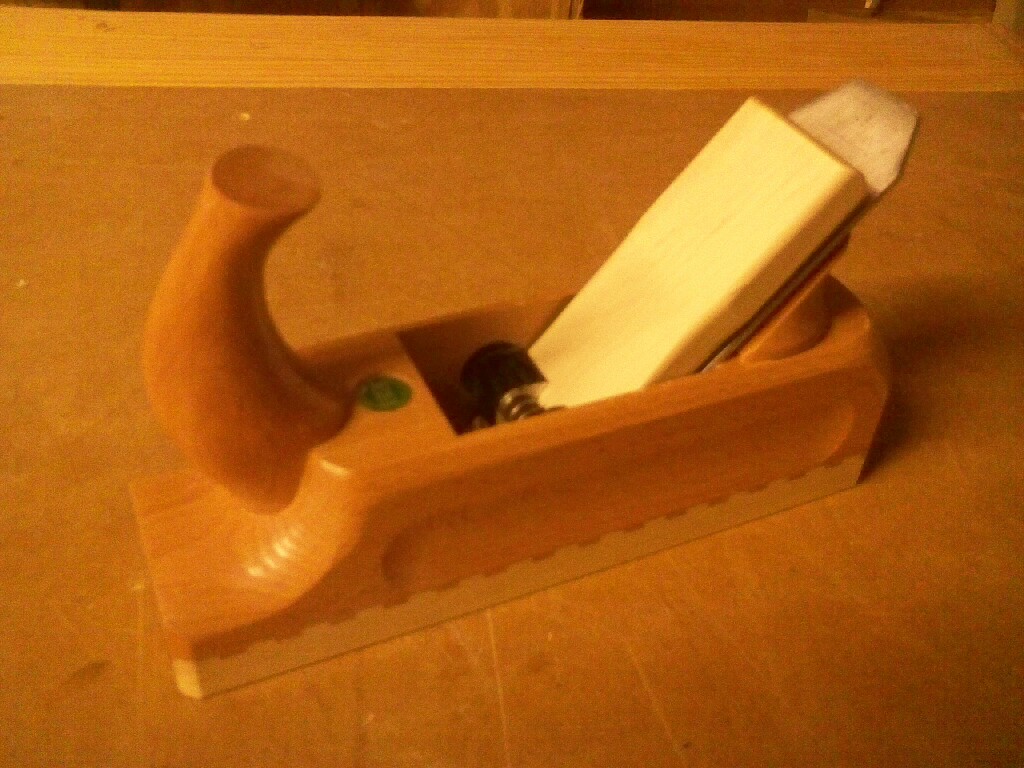

And, what a crosspiece it is. A solid piece of maple – 8″ wide by 2″ thick. Planed and sanded, the ends are tenoned to fit between the uprights. I drilled 1″ diameter holes in the uprights and drove dowels through the uprights and tenon to hold it in place. I think it gives the piece a nice accent.

I sanded and scraped the piece smooth and finished it with a coat of 1# cut of dewaxed shellac sanded smooth with 600 grit paper. Then I applied several coats of wipe-on poly to give a tough finish.

Today, their family has grown to also include a dog, two cats and their much older, bigger, faster and stronger children. And, the glass table top sits firmly on top of the table base, unmoved by the commotion and evening dinners.

Not bad for the strong silent type.