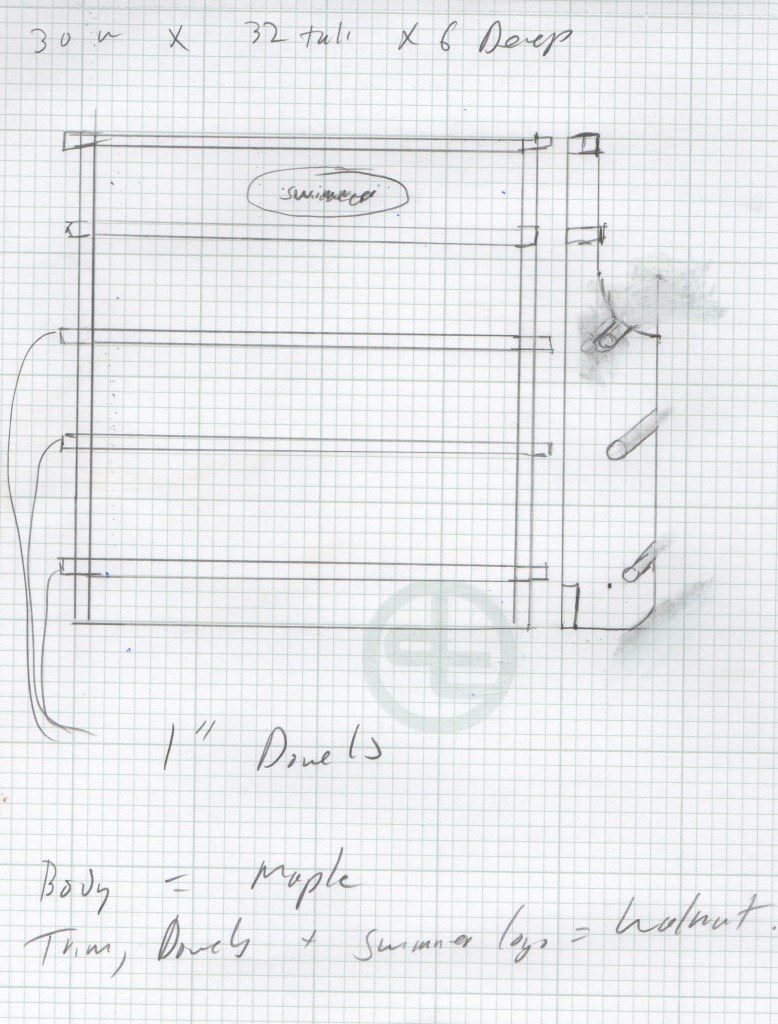

This weekend, I made a whole lot of progress on Kevin’s project for his daughter. I decided that I was going to attempt to do the cutouts with my trim router. This was the first time I had ever tried this type of work, so I steeled my nerves and got to work.

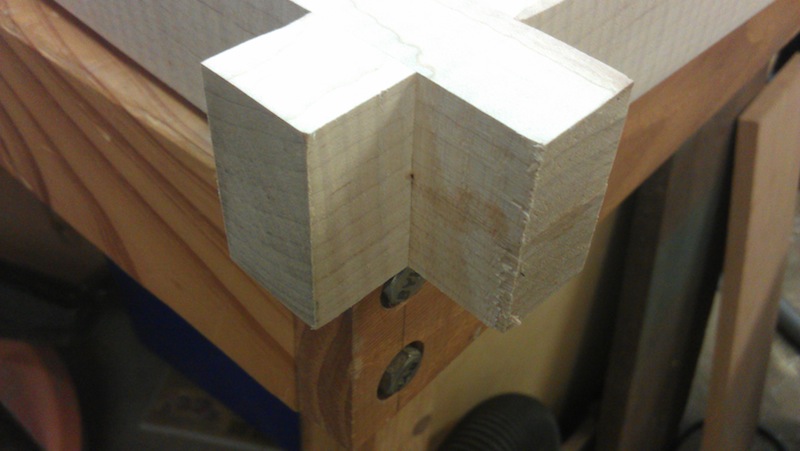

But, first I had to get the boards glued up for this overlay. Using the band saw and planer, I got everything cut to size and thinned down to 1/4 inch. To glue them up, I clamped them down to a waxed piece of MDF with a few cauls on top to keep everything level and a clamp across the sides to pull the joints tight.

But, first I had to get the boards glued up for this overlay. Using the band saw and planer, I got everything cut to size and thinned down to 1/4 inch. To glue them up, I clamped them down to a waxed piece of MDF with a few cauls on top to keep everything level and a clamp across the sides to pull the joints tight.

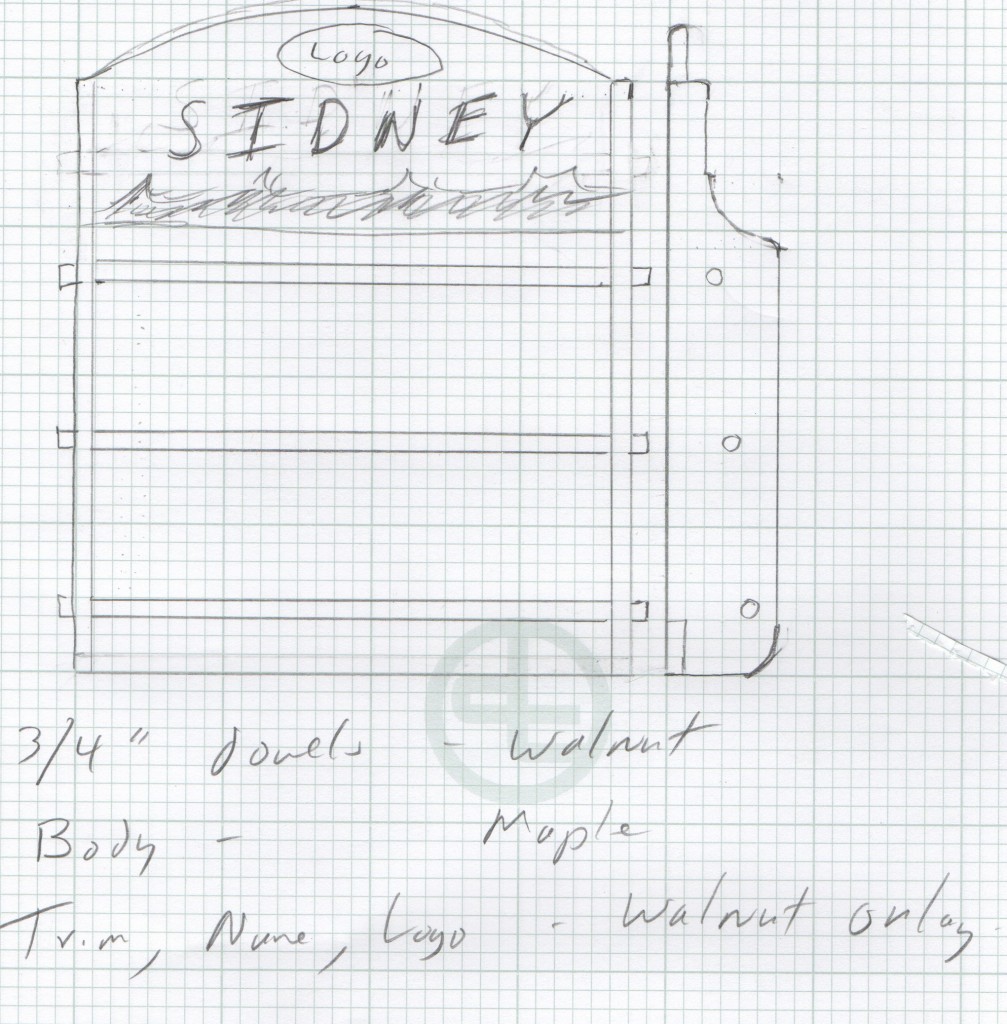

Once I pulled that out of the clamps and gave it a rough sanding and cut the top into an arch that mirrored the top of the ribbon case. , it was time to get it ready for cutting out the name.

I had a little swimmer logo that was going to go on top, and I went to the local copy shop to enlarge Sydney’s name to use as a guide. I ran a few font samples past Kevin, and this is the one he went with. Yes, the font designer made it look all grungy, but I was just going to use it for a guideline.

I had a little swimmer logo that was going to go on top, and I went to the local copy shop to enlarge Sydney’s name to use as a guide. I ran a few font samples past Kevin, and this is the one he went with. Yes, the font designer made it look all grungy, but I was just going to use it for a guideline.

I sprayed the back with some adhesive and stuck the name to the board. How did I center it? Easy, I marked a center line on the board, then folded the paper in half, lining up the edges of the letters to ensure I had it folded exactly in half. Then, I stuck it on the board. That easy.

I sprayed the back with some adhesive and stuck the name to the board. How did I center it? Easy, I marked a center line on the board, then folded the paper in half, lining up the edges of the letters to ensure I had it folded exactly in half. Then, I stuck it on the board. That easy.

One critical piece of equipment I needed was a magnifying visor. This piece of equipment brought the lines I needed to follow into sharp focus, making it tons easier to follow them with the 1/8 inch router bit. While I could have done without this, it made it so much more easier.

One critical piece of equipment I needed was a magnifying visor. This piece of equipment brought the lines I needed to follow into sharp focus, making it tons easier to follow them with the 1/8 inch router bit. While I could have done without this, it made it so much more easier.

It was pretty darned easy routing out the letters, with my DeWalt trim router hugging the curves in the letters with ease. I mean, this kind of stuff was fun! I had my hearing protection on, listening to the games in the first week of the NFL season, stopping only to watch the Buccaneers lose in the final few seconds of their game. Bummer.

It was pretty darned easy routing out the letters, with my DeWalt trim router hugging the curves in the letters with ease. I mean, this kind of stuff was fun! I had my hearing protection on, listening to the games in the first week of the NFL season, stopping only to watch the Buccaneers lose in the final few seconds of their game. Bummer.

It wasn’t long before I had everything cut out and glued into place. You know what? I don’t think it came out bad at all. In fact, I’m pretty darned proud of what the result was. Now, for a lot of finish sanding, and the a good finish for the swimming sensation…

It wasn’t long before I had everything cut out and glued into place. You know what? I don’t think it came out bad at all. In fact, I’m pretty darned proud of what the result was. Now, for a lot of finish sanding, and the a good finish for the swimming sensation…