I like to watch comedians perform. Going to a comedy club is – well – a barrel of laughs for me. If I can’t go, I’ll tune in to Comedy Central for my funny fix. Each comedian approaches the material from his or her own point of view and with his or her own quirky observations. From the full-force in-your-rapid fire delivery (think Gilbert Gottfried or Sam Kinison) to a more laid back, mellow approach that throws you off guard (Bob Newhart or Steven Wright), there’s someone out there who can leave you doubled over in laughter.

I still remember one of the stand up routines Steven Wright did. He would just deliver deadpan lines, one after another, each a little more offbeat than the last.

I’ve been doing a lot of abstract painting lately, extremely abstract. No brush, no paint, no canvas, I just think about it.

Right now I’m having amnesia and deja vu at the same time. I think I’ve forgotten this before.

And, one of my favorites from the show…

I have a map of the United States… Actual size. It says, “Scale: 1 mile = 1 mile.” I spent last summer folding it. I also have a full-size map of the world. I hardly ever unroll it. People ask me where I live, and I say, “E6”.

It was so funny because it was just so absurd. And, later as I was in the shop thinking about the bit, a thought hit me…is there ever a time when a full-sized map would be useful?

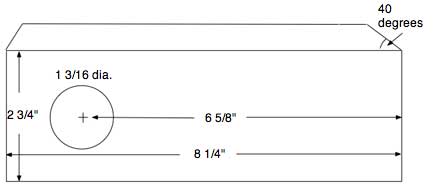

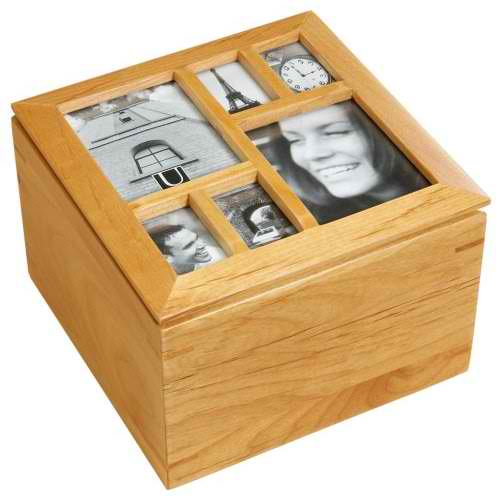

I didn’t really need to look any further than my shop for the answer. I am getting ready to start on a new project – a ladder-step looking bookshelf made of some cool looking cherry from my friends at Bell Forest Products – and I have yet to cut my first board. In fact, the piece right now hasn’t seen anything more than a drawing I made on a sheet of 11 x 17 graph paper.

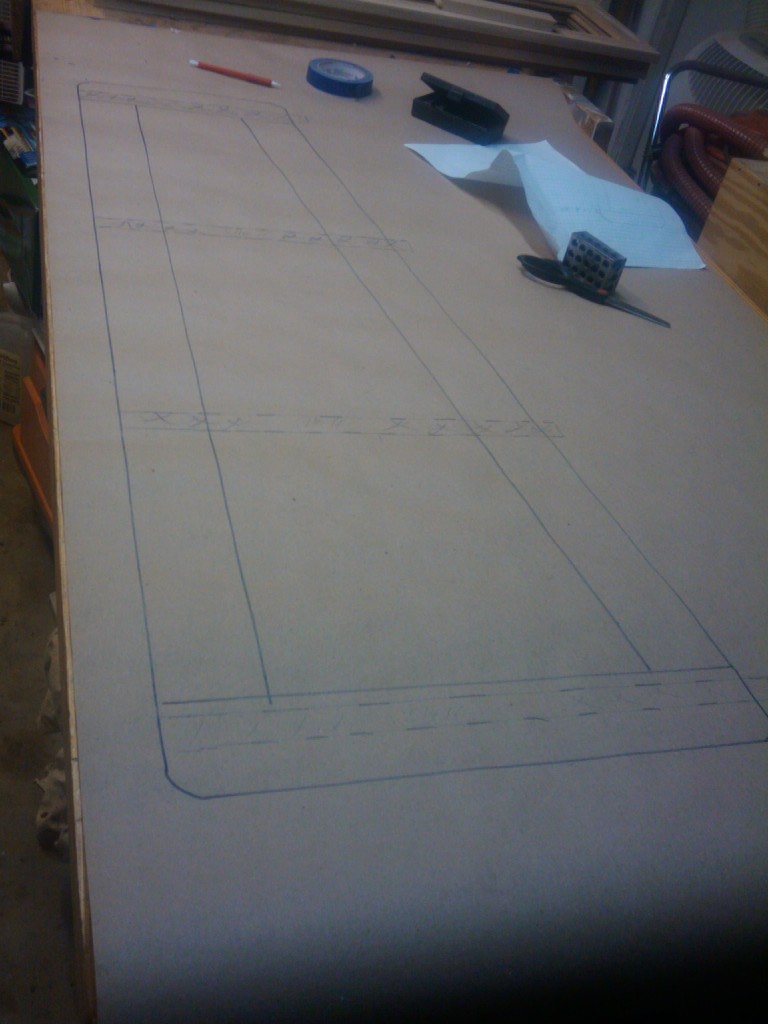

So, I took the drawing into the shop with a roll of brown builder’s paper, some drawing tools and a cool glass of iced tea.

Using a pencil, a ruler, and a 48 inch rule (can’t call that a yard stick, right?) I marked out the critical measurements. Length of the bottom and top boards, height and depth of the piece and the locations of the shelves. After I marked them, I connected the dots. There. A full-size rendering of the bookshelf sides. That simple.

Why on Earth would I do something like this? Well, there are plenty of reasons. As I cut each of the pieces for the bookshelf, I can hold them up to the drawing and compare sizes. I can use my sliding bevel to get accurate angles for the sloped front leg. And, it finally gives me a look at just how deep this bookshelf is going to be. I’m glad I did this, because I think 18 inches at the bottom of the shelf is just a tad too deep. I may be able to talk to the client and ask her about reducing the width two inches for a slimmer appearance.

I’m hoping by doing this step, I can prevent giving each of you more material for your own stand up routines!