One of my favorite movies of recent years was The King’s Speech. What an awesome film. It followed King George VI of Great Britain and told the story about his stammering problem and how he overcame it. The culmination of the movie was the memorable speech he delivered to his subjects on the occasion of the start of World War II, helping to steel the resolve of his island nation.

It’s a good thing he came to power, because his brother, Edward VIII was a real weenie. Rather than take the advice of his counselors, he chose to continue a relationship with American divorcee Wallis Simpson. She was less-than-reputable, allegedly having several suitors while dating the Prince of Wales, later the King of Great Britain. She also treated the future King George VI and his wife in a manner not befitting their status as members of the royal family. Often seen as vain and self-centered, she was quoted as saying, “You can never bee too rich or too thin.”

This quote later became the rallying cry of fashionistas and super models strutting the latest designer clothes on the runways of Paris and Milan.

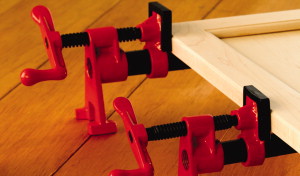

While I’m neither too rich or too thin, I do know of a similar expression in woodworking circles that seems just as applicable… you can never have too many clamps. Basically, you need the clamps in your collection to hold wood together while you glue, mark out joinery or otherwise work on a piece of wood. Clamps should be strong, hold well and easy to deploy when they are needed.

Since most woodworkers don’t have the financial wherewithal to afford every single clamp out there, we need to take the time to explore the different kinds of clamps that exist and which ones can create the basis of a workable collection. I’m sure that some of you will write me to ask why I didn’t include your favorite. Just remember, we’re looking at clamp 101 here, so bear with me. By the way, the awesome folks at Bessey Tools helped me with my research. Nice folks.

The pipe clamp: What many people think about when they think clamps. They are exceptionally affordable – you buy the the head assembly and tail piece together, then attach them to a length of iron pipe you can find in any home improvement center. They are perfectly adequate for most clamping purposes, giving a lot of clamping power. You can even use a pipe coupling and attach two lengths of pipe together, making uber-long clamps. The down side is they are heavy. Black iron also reacts with water-based glues, staining your wood.

The pipe clamp: What many people think about when they think clamps. They are exceptionally affordable – you buy the the head assembly and tail piece together, then attach them to a length of iron pipe you can find in any home improvement center. They are perfectly adequate for most clamping purposes, giving a lot of clamping power. You can even use a pipe coupling and attach two lengths of pipe together, making uber-long clamps. The down side is they are heavy. Black iron also reacts with water-based glues, staining your wood.

The F-style clamp: Also known as bar clamps, these have a head that is fixed on one end of the clamp, and a sliding tail piece that allows you to make large adjustments. Once snugged up to the work piece, you apply pressure on the clamp by twisting the handle, extending the bottom screw of the jaw to apply pressure to the work piece. Much lighter than pipe clamps, they are more maneuverable. With their smaller clamp pads, aggressive tightening can leave crushed areas, so either watch how tightly you crank them down or use a caul to help distribute the load.

The F-style clamp: Also known as bar clamps, these have a head that is fixed on one end of the clamp, and a sliding tail piece that allows you to make large adjustments. Once snugged up to the work piece, you apply pressure on the clamp by twisting the handle, extending the bottom screw of the jaw to apply pressure to the work piece. Much lighter than pipe clamps, they are more maneuverable. With their smaller clamp pads, aggressive tightening can leave crushed areas, so either watch how tightly you crank them down or use a caul to help distribute the load.

Aluminum bar clamps: Very similar in appearance to many other kinds of clamps, you’ll be able to recognize these things by their light weight. Made of aluminum rather than iron or steel, these babies are very easy to maneuver and give a great amount of clamping force. They also tend to resist bowing when pressure is applied because the aluminum is drawn into a rigid channel form. The best ones are made from aircraft quality aluminum, and they can cost a bit.

Aluminum bar clamps: Very similar in appearance to many other kinds of clamps, you’ll be able to recognize these things by their light weight. Made of aluminum rather than iron or steel, these babies are very easy to maneuver and give a great amount of clamping force. They also tend to resist bowing when pressure is applied because the aluminum is drawn into a rigid channel form. The best ones are made from aircraft quality aluminum, and they can cost a bit.

Parallel jaw clamps: These are the big daddies in the clamping world. Bessey’s K-Body clamps were some of the first out there, and they are the type I reach for most of the time. They have an enormous clamping area on both faces, and can be used in several different configurations. While they do cost more than your average pipe or bar clamp, they are solid performers and make clamping a whole lot easier.

Parallel jaw clamps: These are the big daddies in the clamping world. Bessey’s K-Body clamps were some of the first out there, and they are the type I reach for most of the time. They have an enormous clamping area on both faces, and can be used in several different configurations. While they do cost more than your average pipe or bar clamp, they are solid performers and make clamping a whole lot easier.

Squeeze clamps: These one-handed clamps are as convenient and handy as the day is long. For most of my small-project glue ups, I reach for these. Also, when I have to attach something like a stop block to my crosscut sled, I reach for these babies. You can get a decent amount of pressure on them, and they release by tripping some mechanism that releases the clutch on the bar. I have seen these as long as 36 inches, but my collection seems to be mostly in the 6 to 12 inch range.

Squeeze clamps: These one-handed clamps are as convenient and handy as the day is long. For most of my small-project glue ups, I reach for these. Also, when I have to attach something like a stop block to my crosscut sled, I reach for these babies. You can get a decent amount of pressure on them, and they release by tripping some mechanism that releases the clutch on the bar. I have seen these as long as 36 inches, but my collection seems to be mostly in the 6 to 12 inch range.

Spring clamps: Just like large clothes pins, these babies use spring pressure to hold the jaws shut. Again, these are light-pressure clamps and they have limited opening ranges, so don’t count on them for a lot of glue ups, but when you need to hold a molding in place or some other delicate job, they are more than up to the challenge.

Spring clamps: Just like large clothes pins, these babies use spring pressure to hold the jaws shut. Again, these are light-pressure clamps and they have limited opening ranges, so don’t count on them for a lot of glue ups, but when you need to hold a molding in place or some other delicate job, they are more than up to the challenge.

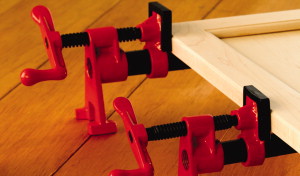

Strap or band clamps: Not every project we build has 90 degree corners. Some projects have crazy angles (chairs come to mind) or are round (or mostly round in the case of something like an octagon). In those cases, it may be tough to get a standard clamp to work right. That’s why these clamps are just so darned handy. Basically, they consist of a nylon strap, some mechanism to take up the slack and tighten the grip, and possible some corner guides. These corner guides make gluing up miters very easy. You typically won’t use them every day, but you will enjoy the heck out of them when you need them.

Strap or band clamps: Not every project we build has 90 degree corners. Some projects have crazy angles (chairs come to mind) or are round (or mostly round in the case of something like an octagon). In those cases, it may be tough to get a standard clamp to work right. That’s why these clamps are just so darned handy. Basically, they consist of a nylon strap, some mechanism to take up the slack and tighten the grip, and possible some corner guides. These corner guides make gluing up miters very easy. You typically won’t use them every day, but you will enjoy the heck out of them when you need them.

Handscrews: An old fashioned tool that still is a heavy hitter in most shops. They consist of two large wooden jaws joined by a pair of threaded screws with handles on the ends. By adjusting the handles, you can get the hand screws to open to any angle you wish. You can also use these babies to grasp the back end of a long board when the other end is secured in a vise. This way, the board is supported while you edge plane. I have also used them as a holder for small pieces which need to be routed, giving my hands a little more distance for safety.

Handscrews: An old fashioned tool that still is a heavy hitter in most shops. They consist of two large wooden jaws joined by a pair of threaded screws with handles on the ends. By adjusting the handles, you can get the hand screws to open to any angle you wish. You can also use these babies to grasp the back end of a long board when the other end is secured in a vise. This way, the board is supported while you edge plane. I have also used them as a holder for small pieces which need to be routed, giving my hands a little more distance for safety.

C Clamps: The old tried and true standby. These babies are made with a c-shaped frames and a threaded post that allows the clamp to be cranked into place. While they may seem small and even cute (a word my wife used to describe the first set I brought home), these clamps are capable of providing tremendous clamping power. Again, either watch how much force you use when applying them or use a caul to protect your work.

C Clamps: The old tried and true standby. These babies are made with a c-shaped frames and a threaded post that allows the clamp to be cranked into place. While they may seem small and even cute (a word my wife used to describe the first set I brought home), these clamps are capable of providing tremendous clamping power. Again, either watch how much force you use when applying them or use a caul to protect your work.

Now, I’m sure that I have missed a bunch of specialty clamps out there… there’s no doubt about that. But, these are the kinds of clamps I rely on for the woodworking in my shop, and you will find many of them being put to use every day. Hopefully, this is a starting point for you on your clamp acquisition adventure, and that you find it to be a good starting point on your way to having a King’s ransom of clamps … that STILL will never be enough.