Across Tampa Bay from where I live is the city of Tampa. And, inside the city’s borders, there’s an old part of town called Ybor City, where the Cuban cigar rollers plied their trade, making Tampa America’s cigar city.

On the main drag of that city the Columbia Restaurant. Established in 1905, they serve some of the most delicious Spanish and Cuban food you can find anywhere. The atmosphere is absolutely lush, with fountains, intricately painted tile and the scent of hand-rolled cigars being smoked over at the bar.

The restaurant also features flamenco dancers from time to time. This exuberant – and loud – dance style features elegantly-dressed ladies, handsome gentlemen and the staccato sounds of a flamenco guitar played by an experienced musician. Many of these guitars have a neck made of Spanish Cedar, today’s spotlighted species.

Spanish cedar is a native tree to Mexico, Central America and the Caribbean. The trees can grow up to 100 feet in height, and thrive in well-drained soils.The wood has a fair resistance to rot and insects, which makes it very desirable in the tropics, where these are a very big concern.

The wood can range in color from light brown to a pinkish-red brown. It is very soft and easy to work with. It has a tendency to splinter, so the key are sharp tools. It does have the occasional pitch pocket, which continually ooze resin, so if you don’t plan on sealing the wood, it’s a good idea to try to avoid those areas when selecting your pieces.

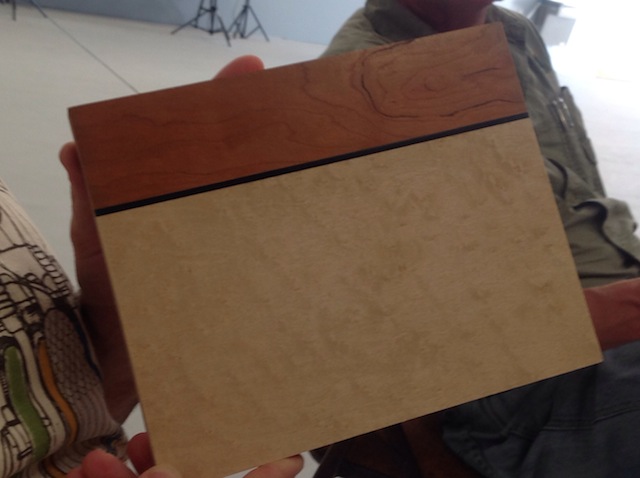

While it may be called Spanish cedar, it’s not a true cedar – closer, instead, to mahoganies. What’s really wild, however, is that it does have the smell of cedars, making it an excellent choice for chests and to line storage boxes for another big product of Ybor City, cigars. In fact, while many humidors may be built on the outside with a variety of different woods, most of them are lined with Spanish cedar to enhance the flavor of the cigars stored within.

While it’s obviously not finished when inside of a humidor, Spanish Cedar does take a great finish. The perfect way to view this is to check out the necks of most classical or flamenco guitars. They are traditionally made of Spanish cedar, and can take a mirror finish.

Reading these descriptions may make you think that Spanish Cedar is only good for small projects. It does well as larger furniture also, making beautiful benches, tables and other projects.

So, they next time you smell a fine cigar being smoked or hear the energetic sounds of a flamenco guitar, be sure to applaud the work that Spanish Cedar does in bringing that to you.