I love this time of the year in sports. The NCAA men’s basketball championships are in full swing, and the competition is fierce. Perennial powerhouse schools such as Georgetown, Duke and the University of Connecticut are out, and long shot schools like Davidson and Western Kentucky are still dancing.

I run a pool for the men’s championship with some friends from around the country. How am I doing? Well, let’s just say my new nickname is ‘Foundation.’ I don’t know how I can get much worse.

Perhaps if I had the chance to see each of the 65 teams entered in the brackets, I might have had a better handle on how they would perform under the bright lights of national attention.

In much the same way, I have picked more than my share of loser tools. After woodworking for ten years, I have a collection of gadgets and gee-gaws that the inventor no doubt thought would change the face of woodworking forever. And, based on the reviews of some users, I fell hard for them, only to be terribly disappointed by their performance.

In much the same way, I have picked more than my share of loser tools. After woodworking for ten years, I have a collection of gadgets and gee-gaws that the inventor no doubt thought would change the face of woodworking forever. And, based on the reviews of some users, I fell hard for them, only to be terribly disappointed by their performance.

If only I had the chance to handle the tools before I could buy them…

Well, this past weekend, I had just that opportunity. The Woodworking Shows expo came to Tampa, and I figured it would be a good idea to mosey over and have myself a look.

If you have ever been to a woodworking expo before, you might be a little jaded by the experience. One of the nearly universal sentiments is the shows aren’t what they used to be. Time was, you were able to go to a show and score an excellent deal on a sweet tool, get to meet the innovators themselves and network with woodworkers from your area. “The Internet is killing the show experience,” many woodworkers claim, because everything you could do at the show, you could easily find or do online.

That may be so, but I have a very different take on things.

That may be so, but I have a very different take on things.

From the moment I walked in to the Florida Fairgrounds just outside of Tampa, I was like a kid in a candy store. The floor of the Fairgrounds arena was covered with booths from manufacturers demonstrating their tools. Other areas were set aside for training sessions. And, the place was packed!

What were my observations?

Well, getting to talk with the representatives of the different tool companies gave me a fresh perspective on woodworking – and the tools I already own. I spoke with Henry Wang, inventor of the Grr-ipper push block system. I had purchased one of the Grr-ippers a few years ago just to make narrow rip cuts on the table saw. Shortly after, I walked away from the booth shaking my head. How could I have gone for two years without knowing what the tool could do?

Every time I look at a tool that I want in a catalog or online, I find myself wondering just how big it is or how it feels in my hand. Is it something that’s substantial I will use for years, or just a use one time and throw it away in disgust type of tool? When I turned a corner at the show and saw a huge booth by Lee Valley tools, my heart started to race. Rack after rack of neatly arrayed tools were on display. I got the chance to feel how the Veritas bevel up smoother plane was different than the Veritas low-angle smoother plane. Something I couldn’t quite understand from the catalog description.

There was a wealth of knowledge there for the taking. Jim Heavey of Wood Magazine was offering a series of woodworking seminars. I watched him for about 30 minutes, and learned about six techniques I am going to add to my work. Sure, the information is out there on the Internet and in books, but I was able to stand next to him and look at how everything was set up. I could even ask questions and get immediate responses as well.

There was a wealth of knowledge there for the taking. Jim Heavey of Wood Magazine was offering a series of woodworking seminars. I watched him for about 30 minutes, and learned about six techniques I am going to add to my work. Sure, the information is out there on the Internet and in books, but I was able to stand next to him and look at how everything was set up. I could even ask questions and get immediate responses as well.

Also, I was able to meet people who shared the passion for woodworking I have. Again, I am an active poster on many woodworking forums, but the opportunity to shake hands with people goes a long way.

I left the woodworking show after three hours a little lighter in the wallet, but the experience was well worth it.

And, it took my mind off of the sting of making such lousy picks in my NCAA tournament pool.

If you are looking for an adhesive to stick your projects together, there are dozens of choices out there. Some you expect to see in today’s workshop (yellow carpenter’s glues). Others are prized for their specific properties such as being waterproof or extremely tough (epoxy).

If you are looking for an adhesive to stick your projects together, there are dozens of choices out there. Some you expect to see in today’s workshop (yellow carpenter’s glues). Others are prized for their specific properties such as being waterproof or extremely tough (epoxy). Ahh, who can forget the heady days of late 1999? The dire predictions of mass hysteria as computer systems crashed around the world. Cults foreseeing the end of civilization and the beginning of the ‘end times.’ Economists hedging their bets on an economic collapse the world hadn’t seen since the Great Depression.

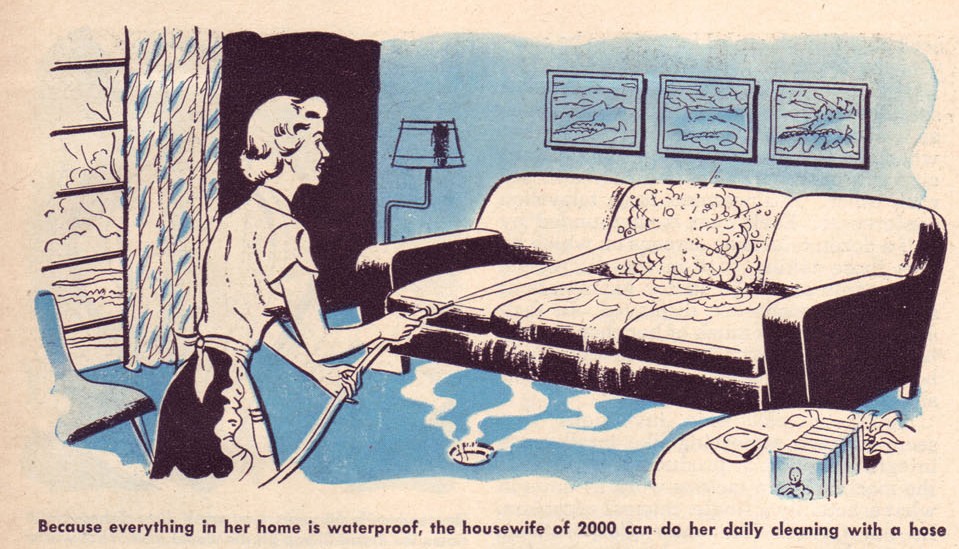

Ahh, who can forget the heady days of late 1999? The dire predictions of mass hysteria as computer systems crashed around the world. Cults foreseeing the end of civilization and the beginning of the ‘end times.’ Economists hedging their bets on an economic collapse the world hadn’t seen since the Great Depression. I recently came across a .PDF of an article written in a 1950 edition of Popular Mechanics called

I recently came across a .PDF of an article written in a 1950 edition of Popular Mechanics called

England and the United States, such notables as William Morris, Gustav Stickley and Edwin Lutyens were driving furniture design into a more craft, hand made aesthetic. Even though they used machinery for some tasks, the furniture spoke boldly to strong lines and the skill of the craftsman. Frilly ornamentation was abandoned nearly altogether in the

England and the United States, such notables as William Morris, Gustav Stickley and Edwin Lutyens were driving furniture design into a more craft, hand made aesthetic. Even though they used machinery for some tasks, the furniture spoke boldly to strong lines and the skill of the craftsman. Frilly ornamentation was abandoned nearly altogether in the  This handbuilt school of design brought with it increased innovation to allow the inexperienced craftsperson to build custom furniture. David Keller perfecting the first through dovetail jig. Delta pushing innovation in table saws. The adaptation of new industrial joinery technology into the home workshop with such items as the biscuit jointer, pocket hole jigs and the Domino.

This handbuilt school of design brought with it increased innovation to allow the inexperienced craftsperson to build custom furniture. David Keller perfecting the first through dovetail jig. Delta pushing innovation in table saws. The adaptation of new industrial joinery technology into the home workshop with such items as the biscuit jointer, pocket hole jigs and the Domino. Woodworking master George Nakashima’s influence is still felt in the works he created and at the furniture shop run by the craftsmen who continue his tradition.

Woodworking master George Nakashima’s influence is still felt in the works he created and at the furniture shop run by the craftsmen who continue his tradition.