So, I just walked in from the shop. Still sweaty and covered with sawdust. My wife is gonna kill me when she sees the mess I left.

I’m here at the computer about to launch into one of my patented stream-of-consciousness posts. If you want to read, please continue. If you would rather look at pictures of gorgeous woodworking made by talented folks, check this out.

No, I’m here at the computer because I have to wonder just where the heck I am as a woodworker. So, I’m working on those bookshelves, and I drag my posterior outside to the shop on a hot, sweaty day after mowing the lawn. I just had lunch and about a quart of Gaorade, so I should be OK in the Florida heat. Heck, I even turned on the A/C to get the shop down to a manageable temp.

I lay two of the sides of this piece side by side and get ready to start routing matching dadoes. Nothing is lining up. Nada. Hmmm…

Funny… when I laid out and cut the pieces, I used stops to ensure accuracy. They should all be identical sizes… right?

For giggles, I laid a square against the back support and the bottom piece to see how square they were.

My next words can’t be typed on this – a semi family-friendly blog.

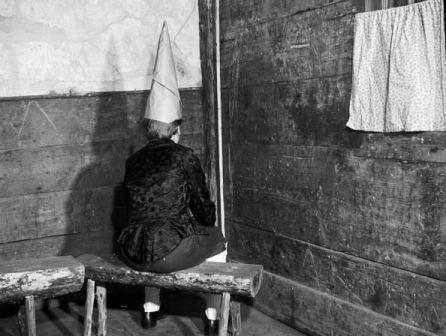

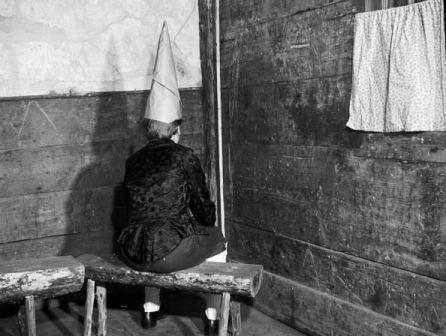

I was so far out of square, it wasn’t funny. On ALL FOUR sides for both shelves. Not off by a whisker off a gnat’s behind over four feet kinda out of square – more like you could drive a freakin’ Mack truck between the back member and the blade of the square. Somehow, during my dowel/mortise and tenon debate, I had failed to use my FREAKIN’ square to check to see if the pieces were going together 90 degrees to eachother. Let me repeat that… I didn’t check to see if the pieces were FREAKIN’ square!

Woodworking 101.

I’m not sure what’s going on here. But, it seems as if the more ‘advanced’ of a woodworker I am becoming, the more I’m forgetting to do the basics right. I was watching Tommy Mac yesterday do some really cool veneer work on his walnut lazy susan thing. “Gosh, that looks like it would be fun to do.”

But, gosh, getting to that point in a project to try something more advanced requires knowledge and application of skills previously learned.

There’s something more, though….

Yesterday, I was flipping through a photo album of some of my earlier pieces. There I was, grinning like a fool standing in front of what were some OK looking pieces. Some were really eye-catching, while others were held together with bubble gum and spit. The one thing that I do remember in common with all of those projects was how excited I was to be building them. I can remember waking up before my wife and my at the time little kids and sneaking into the garage to check on that glue up I had put into the clamps in the wee hours of the morning. I can remember that rush that I felt pulling a board off the table saw with a relatively straight and burn-free rip and thinking to myself that I was the master of all things xylem.

Now, I can literally go days – heck weeks – without even setting foot into the shop. I don’t even bother cleaning up and arranging my tools for the next shop session’s work. I don’t race home, wolf down dinner and see how many joints I can cut before I have to tuck the kids in their beds. Am I becoming the most talented tool collector on my street? The provider of the prettiest sawdust for my neighbor’s compost pile?

Could it be I’m not in love with woodworking like I used to be?

Probably not. It could be that it’s 98 humid brutal degrees outside, that I’m in the busy part of my work year and I had a bad assembly on my project. I’ll rip the piece down, salvage what I can (Maybe even turn some of those uprights into shelves or something like that) and get back in the saddle again.

Maybe I just need a vacation.. or to meet up with some other woodworkers to get that spirit back!