In case you were wondering, I am an Italian American. And, I’m from northern New Jersey, just outside of New York City. So, I can say that I lived in one of the premiere centers of Italian cuisine in the United States.

Pizza. Strombolis. Calzones. Zeppole. Man, that stuff is awesome. And, it’s tough to find food like I used to have up in Jersey. (However, if you find yourself in the Tampa Bay area, Sardo’s Pizza on Ulmerton Road in Largo is a welcome taste of home.)

Since this is the case, I often find myself cooking at home. The recipes that my mom and my grandmothers used to cook. I make my own gravy (no, it’s not tomato sauce… it’s GRAVY). I make my own lasagna. Meatballs. Braciola. Cutlets. The works. Heck, I even make my own pasta when the mood strikes me.

While many of these dishes are different, they all seem to have a few basic ingredients in common. Garlic. Tomatoes. And, most important of all – olive oil.

Ahh, olive oil. That magical substance that tastes so darned good… and it’s good for you. It’s high in monounsaturated fats… good ones that don’t clog up the arteries. It was harvested from olives in the Mediterranean basin as far back as 5,000 years ago and helped build empires.

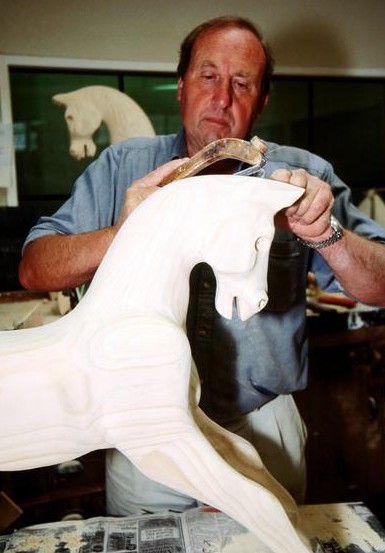

“Oh, I’m a big olive oil fan,” said Eric Poirier of Bell Forest Products. “It’s great on a salad or some fresh Italian bread. But, if you love the oil, you are going to love the wood for your projects.” The wood of the olive tree (related to ash trees) has a greenish brown tint and a very distinct and attractive grain pattern. The wood is exceptionally strong and hard (sharing that trait with its cousin ash), and works very well. It can take an excellent polish, which makes it a natural for pens and other small turned items.

Since the trees are pruned primarily for harvesting their valuable fruit, they typically won’t grow very tall. This means, of course, that you are very rarely going to find long boards, so if you are looking for a small project, hey, olive may be your wood.

While it’s easy to see why olive is a great wood to work with, it’s the smell that sets it apart. “It has a very sweet, heady scent when you cut into it,“ said Eric. “You just might wish they made an olivewood scented aftershave.”

Since olive trees grow well in the Mediterranean basin, people have known about them for a very long time. This includes the holy lands mentioned in the Bible, Torah and Koran. “Because of this, olivewood is a very popular choice for items with a religious theme.”

Many countries have strict regulations on the harvest of olive trees. However, enough trees are culled to provide hardwood for woodworkers to do their thing.

So, while you are sitting and thinking about how you can incorporate some olivewood into your next woodworking project, slice up a ripe tomato and some fresh mozzarella cheese, hit that with a little salt and pepper, add a few fresh basil leaves and drizzle that with some high quality extra virgin olive oil. It may not help you figure out what to build, but oh, it tastes so good….