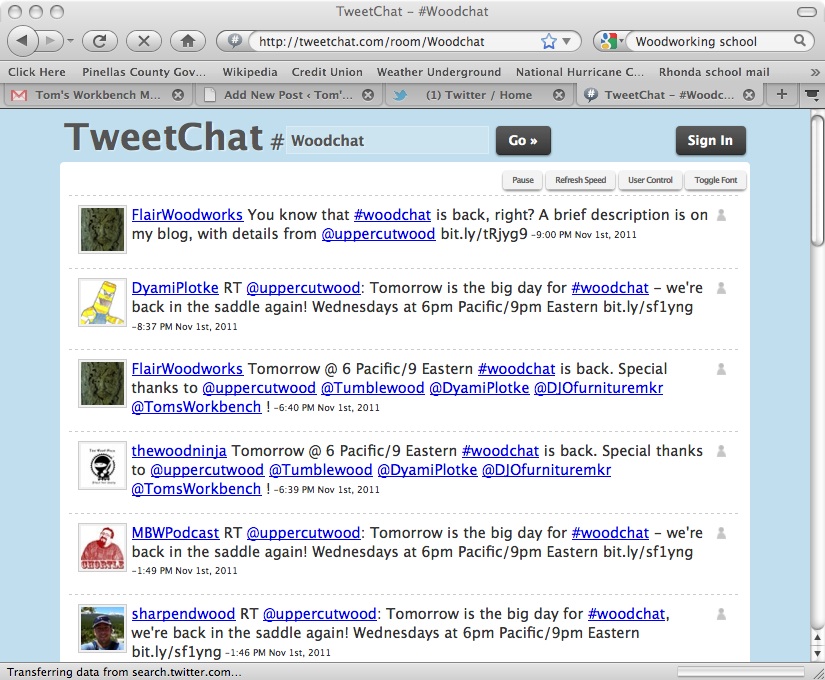

People have often wondered exactly what I have been thinking. I’ve been told more than once that I really need to have my head examined.

(For those of you who may be concerned… relax. I’m undergoing a 24 hour EEG test just to verify that I truly am OK after a recent health issue. Everything so far looks A-OK, and I’ll have the results for sure in the next few days.)

Since I have the rig on, I’m sure the doc is going to be surprised at just how much I’ve been thinking about how I need to fix a boo boo on another project. You would think by now I have made every single possible mistake there is to make, but I am pretty resourceful.

Basically, here’s the situation. New project – new issues. I am building a pantry for a friend of ours. I ordered the (EXPENSIVE!) high quality maple plywood and hardwood for the build, and I used the Festool track saw to cut the pieces down to size. This is going to be a piece of cake, sez I, because I have used this before and I know all of the pitfalls of making cuts without using a self-squaring rip fence.

Well, If you put the track of the saw down where it’s not square, and then you make a cut, you will have a perfectly straight cut that just doesn’t quite measure up square. That’s what happened when I cut one of the sides, and I didn’t discover my boo boo until after I had the piece glued and screwed together. Dangit.

So, I thought I could hide the issue by cutting a long wedge from a maple board and gluing the piece down to the plywood before I put the face frame on. Gosh, that plan stunk. There’s no way I am going to hide this problem.

So, I got to firing those brain cells off – how on Earth am I going to fix this project. The client was looking to get a pantry like the one I have in my kitchen, and I did a good job ripping the sides on that one straight and true on my table saw.

Think, Tom. THINK! (By now, the brainwaves are just bouncing all over the place. The doc is going to have his hands full working on this one…)

That’s when a flash of inspiration hit me. When you look at the sides of most cabinets, they are very plain affairs. Just flat end panels sitting there in their monolithic glory. But, I can also remember a book by Danny Proulx about building your own kitchen cabinets, where he too lamented the fact that slab sides tend to look a little boring.

So, why not take the opportunity to turn my mess up into a design feature?

Danny’s idea was to dress up the end panel of a project like you would the doors of your project to give the piece a little more visual interest. A great idea, especially since I’ll be building the doors for the project, and can use the bits to create a ‘mock panel’ for the sides. Basically, I’m going to mill some maple down to 3/8″ thick, bead the edges and then picture frame the pieces on to the cabinet… making the ends look pretty fancy…

Sure, it will cost a little extra and take some additional milling to make it right, but the finished piece will look totally awesome.

That’s enough thinking for one day… I’ll let my brain sit back and kick its feet up to celebrate another job well done!