Ahhh, dovetails. How can you go wrong with such a classic joint?

Oh, wait, never mind… My efforts to hand cut them have met with disaster, ridicule and – at last count – no fewer than 14 petition drives to get me to quit woodworking entirely.

So, when I need that tried-and-true joint in my work, I turn to the router and a jig. As I had written Monday, I’m a project kind of woodworker… not a process guy. I do pay close attention to how I woodwork, but I’m not about to take weeks during a project to hand-cut dovetails when I can blast ’em out on a jig.

For years, my go-to jig has been my Keller Journeyman. I love the heck out of it – and have abused the heck out of it as well. I’ve lifted the router out of the cut too many times, tearing up the phenolic body terribly.

My Kehoe jig is awesome, giving me great dovetail splines. Sometimes, though, they do look a little out of place on a more traditional piece, so I need another option.

That’s when David Venditto of Infinity Cutting Tools asked me if I wanted to try the new Leigh R9 jig. Always game for a challenge, I took him up on the offer. And, I have to say I was thoroughly impressed.

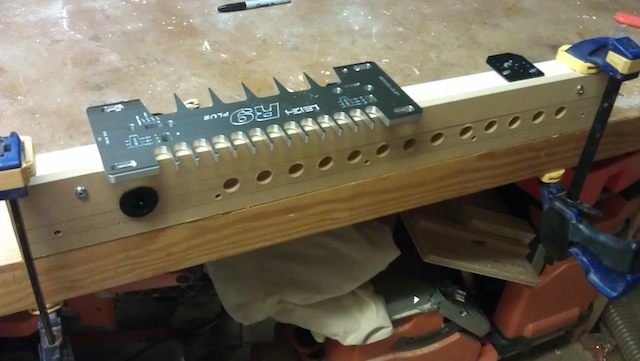

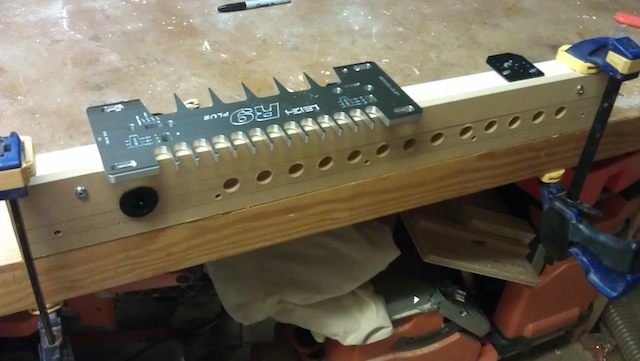

The jig comes flat packed with everything you need to get it working, except for the wood needed to create a beam for the jig to ride on. Accuracy when building this beam is critical. My beam has a piece of construction 2 x 6 southern yellow pine backing and an MDF two-part face. The bottom part is a permanent fixture to the piece, while the top part of the fence is a sacrificial fence for the router bit to ride into, preventing tear out.

The hardware with the kit is top-notch. It even comes with a pair of clamps you can use to secure your workpiece in place as you rout. The plate that guides the router is made of a heavy-duty aluminum etched with the necessary markings on top. It took a little time studying the manual to get an idea of what everything was used for, but, once I read up on it, things when smoothly.

Instead of a router bearing, the jig uses an eccentric guide bushing that allows you to really fine-tune the fit of your pins and tails. Those adjustments are in the order of thousandths of an inch… critical measurements when it comes to cutting this tightly-fitting joints.

Not only does the jig allow you to cut dovetails, it also comes completely equipped to cut box joints as well. All of the proper bits are included. Very handy stuff.

The manual is really where this baby shines. Leigh has spent a lot of time carefully laying out a well-written, fully-illustrated guide that will show you step-by-step how to assemble and cut with the jig. Believe me, if an ‘accuracy challenged’ guy like me can work with it, anyone can!

While I have always shied away from very expensive dovetailing jigs (some of Leigh’s offerings can really stretch the woodworking budget a lot farther than it can go), the R9 is a solid offering from Leigh that is available at a reasonable price point. And, given the cost of quality dovetail saws and chisels these days, you might just find it more economical to cut your dovetails this way instead of the old school method.