When you woodwork, you really need to be able to see what you are doing. Clearly.

Part of that is being able to extract the dust, chips and shavings from your work area. You probably also want to wear some high quality eye protection – corrective if needed. And, you need light. Lots of it.

There are many schools of thought when it comes to lighting your shop. Some advocate 100% natural sunlight, allowing you a raking view of the project you are working on. Others recommend flooding your shop in scads of overhead light bright enough of attract the attention of 747 pilots on a landing approach.

For me, well, my lighting situation stinks. Although it is much better than it used to be. At one point, the garage had one single ceramic screw-in light fixture. That was it. Man, was that place a dungeon.

Since then, I have installed a pair of two-bulb fluorescent lights. Those suckers throw a whole lot more light than used to be there. And, for a while things worked out well. I even added a hanging shop light over my bench to get some additional light where I was working. But, ya know, that arrangement always seemed awkward. I had to turn the lights on, and then pull a switch to add more light. Invariably, I would forget to turn the light over the bench off, and there were times when I would walk out to the shop after a day or two, and discover it hadn’t been turned off.

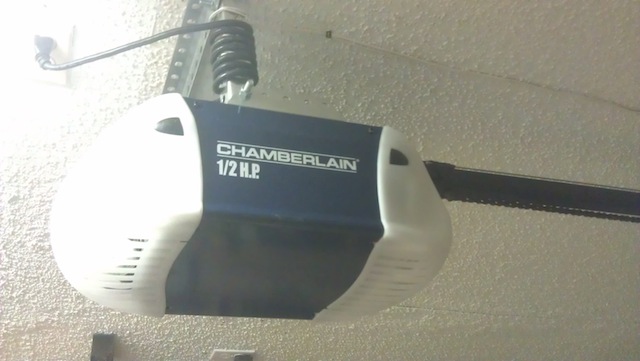

So, I decided to do a little something about my lighting situation. First things first, however. My automatic garage door opener hadn’t worked in about two years. I would manually open the door when I needed access to the shop, but the vast amount of time, it would stay closed. Recently, the big home improvement mega store was offering a great deal on a garage door opener, and installation included lubrication and balancing of the garage door. The best part? The unit came with two lights – one in front and one in back. I put a pair of compact fluorescent light bulbs in them that have the equivalent of 150 watts. Since the run on considerably fewer watts than advertised, they really boosted the light output.

What next? Well, My plan is to reuse the existing lights, placing them in more advantageous locations to help light more of the shop. The next step is to install a new eight-foot long shop light in the middle of my shop. This unit is pretty cool, because it uses four four-foot long bulbs, instead of the much more expensive eight foot bulbs. I will also link the three separate lights together so they all come on with a flip of the switch. With these new lights and the garage door opener, it will definitely brighten up the area.

I also need to put some lights up at the miter bench to throw off a little more task lighting, get a magnetic base light to get some more light over by the band saw, and I think I’ll be good to go.

And, if I do it soon, I might have all the lighting upgraded before I have to start wearing cheaters!