Monkey. Iggy, the Trained Shop Monkey.

I’m not 100% certain what’s going on with Tom these days, but I’m not sure that I like it. He has this thing – all of a sudden – about James Bond movies and the old Mission: Impossible TV series. He’s been at it non stop for about a week now. His poor wife had the bad idea to rent the newest James Bond film Skyfall, and he just went on a rant fest about the movie. “It’s not as good as the old movies! There were no gadgets! Where are the Bond girls?”

Since then, he’s been forcing his poor kids to watch those movies and those TV shows pretty much non stop. I can hear that Mission: Impossible theme song out in the shop, even over the sound of the router. He’s obsessed.

But, the movies and shows do bring up some interesting discussion. I mean, they did do some great stuff with those spy gadgets. No matter how bad the situation got, they always had the ge-gaw or doodad that was able to open the door, eavesdrop on the most important conversation or make a clean getaway. How many times do we as woodworkers find ourselves looking for that one particular tool to get the job done?

That’s why I was so happy to receive a few sets of special super-agent drill bits from our friends over at Bora Tools They carry the Fisch brand bits, some really high-quality babies. These bits are ready for their special mission – drilling wood.

Drill bits, you must be thinking. What’s so special about those? Unlike regular split-point bits, those designed for drilling wood provide some advantages for the task. Split point bits can skate or walk when they contact a wooden surface. If you take the time to create a center point where the tip of the bit can bite, that can improve things. But, I discovered that this skating can really reduce accuracy when you need to do something very precise, like bore holes to make a mortise.

Enter the brad point bit. These bits have a center point that helps the bit start true, as well as cutting lips on the outside perimeter of the hole. This allows the bit to score the outside of the hole, allowing for a very clean entrance. Twist bits can rip out wood fibers when they enter the hole, leading to some ugly holes. Deep flutes also assist with chip extraction, a big plus when drilling into any kind of wood – soft, hard other wood product like MDF. They also drill flat-bottom holes. This may not seem like too big of a deal (especially for Double-O-Six-and-two-thirds), but it is huge, especially when you are doing precision work like boring for doweling or inserting parts.

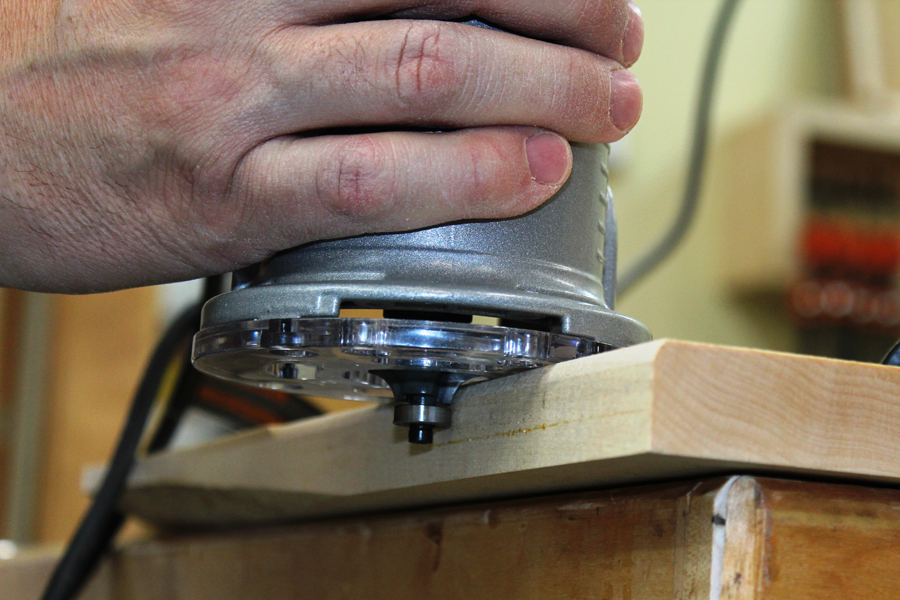

Once you get to a bigger size, enter the Forster bits. These babies do many of the same things that the brad point bits can do, only for much bigger holes. Rather than looking like traditional twist bits, these have a shaft and a cutting head forged from the same steel. Since the head can be up to – and larger than two inches in diameter, they do a good job boring larger diameter holes. Once again, there is a center point that helps secure the bit before it enters the work, and the outside rim of the cutting head shears the perimeter of the hole, giving a very smooth edge. Between the outside cutting edge and the center point, sharp angled edges cut what looks like plane shavings out of the wood. These bits also excel in cutting holes that other bits would have a hard time with – angled holes, holes that go past the edge of your board… the works.

With a set of bits like this, any secret agent would be more than equipped to tackle even the toughest mission. Now, how do we pry Tom away from the couch and get him back into the shop? Yes, Tom, I see the secret agent in a tough predicament… sigh…