I have a friend who is a Civil War Reenactor.

There, I said it. It’s almost like admitting I am in a rehab program. “Hi, my name is Tom, and I have a total addiction to Tic Tacs.”

Well, anyway, my friend derives tremendous enjoyment from getting all gussied up in his scratchy wool suit, sleeping on the hard ground and eating hardtack. To me, this sounds like doing hard time at some correctional institution, but, hey, that’s just me.

This hobby is a good one for him to have, because he is also a history teacher at a local high school. He once worked at my office helping us with some emergency management work, and we frequently got into long discussions about Civil War era politics, personalities and tactical matters.

And, while my friend wears blue, he is a native Mississippian, so does have a soft place in his heart for Dixieland.

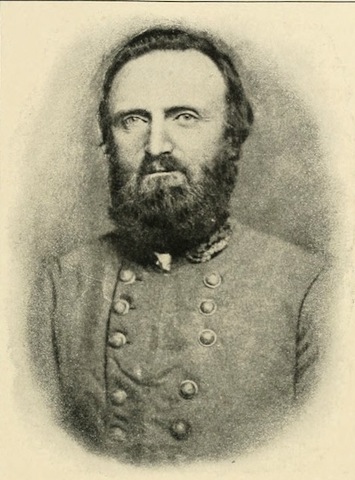

One of the most intriguing personalities we discussed was Thomas “Stonewall” Jackson. This famous southern general was a tactical and strategic genius, often leading terribly outnumbered forces against well-equipped Union troops and achieving startling victories.

One of the most intriguing personalities we discussed was Thomas “Stonewall” Jackson. This famous southern general was a tactical and strategic genius, often leading terribly outnumbered forces against well-equipped Union troops and achieving startling victories.

He was well known for being able to determine where smaller divisions of the much larger Union army were located, and attacking each of them in turn, moving from smaller victory to smaller victory until he was able to totally unnerve Union generals sent to confront him.

You know, when we start woodworking, there are many times that there are projects that look too difficult to overcome. For me, the first time I remember that happening was when someone asked me to build an entertainment center for them. They were going to pay for a low Craftsman-style piece, and they were pretty specific on what they wanted.

Had I ever built doors before? Nope. How about glass doors with an applied grill? Nope. Cut a curved bottom apron? Never.

But, I wasn’t about to let that get to me. Oh, wait, I was. I was nervous as heck. How on earth was I going to do this? It was a complicated project, and I was overwhelmed.

That’s when I decided to go all Stonewall Jackson on it. The folks over at the Woodworker’s Website Association told me that things would be easier if I broke each of the components down into smaller sub assemblies.

So, I tackled the panels, and how I was going to join them to the square legs. How I was going to do frame and panel construction. How I was going to rout out for the glass inserts into the middle doors. How I was going to do the doors on the side compartments. How I was going to joint and glue up the top slab.

Are there things I would have done differently? You bet. Was the client happy? Absolutely. Did the client pay for the project? Indeed he did.

Remember, as a woodworker, nothing is really outside of your abilities. Sure, it may take longer, and you may need some practice cuts, but by taking each step one at a time and asking for help if you need it, you will find that the project that left you sweating in anxiety is something you will master.

And, at that point, you can declare victory.

Now, for today’s haul of awesome articles:

- Highland Woodworker: Woodworking Tips Map

- The Renaissance Woodworker: How to help others get woodworking

- Upside Down Table Saw: It’s get woodworking week … and I’m sick

- Hock Tools: School Days (Get Woodworking)