I have got to confess, I feel as if the past few weeks I have been going through the motions here on the blog. Once I had my health scare earlier this month, I really didn’t have the strength, energy or – quite frankly – confidence to get out back into the shop to do any woodworking. It’s also a tough time of the year to be in the shop. After all, the ‘feels like’ temperature is well over 100 degrees, which really didn’t help.

But, this weekend, I took a page out of cowboy legend Gene Autry’s playbook. I identified a job that had to be done, headed out to the shop early in the day (when it was cooler) and got back in the saddle again.

The project was a simple one – to build a pair of doors to enclose the old TV area of the corner entertainment center. With the new front unit, this piece is now being converted to full storage for our old photo albums, school yearbooks and other miscellaneous stuff we have stashed around the house.

This was a very early project I had built, and, at the time, I built the doors using mitered frames grooved to hold some 1/4″ plywood. It was an easy way to do the deed without any real fancy joinery, and the results have lasted more than 12 years so far with no issues.

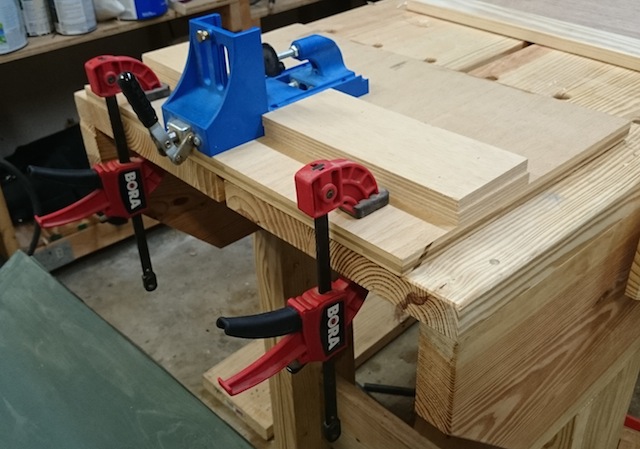

So, I got to work. The beauty of building doors this way is that you don’t need a whole lot of tooling. I first measured how tall and wide I wanted the final doors, then cut them to size using my miter saw. Since I have it measured out to cut accurate 45 degree angles, I was able to get all of the frame pieces cut accurately in no time flat.

With the pieces cut, I laid them out on the bench and marked where I wanted the groove for the plywood panels. With those marked, it was easy to test cut on some scrap to make sure two passes over my standard combination blade would cut a sufficiently wide kerf to house the panels. Very simple.

I used my square assembly jig to lay out the pieces and mark the corners. From there, I measured for the size of the center panels for the plywood and got everything together for the assembly.

To help hold the miters together, I went with a biscuit joint like I had used on the four original doors. It had been a while since I used that tool, but when I was building this piece back in 2002, it was state-of-the-art for me. Fortunately, it was easy to get back into the swing of things with the jointer, and before I knew it, I had all four corners cut and ready for glue.

Once the glue dried, I brought them inside for a quick dry fit. They worked nicely. Now, I just have to sand, prime and paint the doors to match, then attach the hinges and handles, and that project will be off the list of things to do.

And, I’ll be back in the shop once again to get some more work done…