Here in the United States, today is Labor Day. Most of us are relaxing, enjoying barbecues and contemplating the end of the summer and the beginning of the – gasp – blizzard season.

But, that doesn’t mean that everyone is off. I mean, police, fire and emergency medical types are on the job today. Reporters, videographers and news producers are on the job. And, as we all know, even superheroes are on the job.

Do you really think that if the bat signal is given that Batman would neglect the call? That Spiderman would let Doc Oc run amok while he sat at the beach? That Wonder Woman wouldn’t spring into action if Cheetah was out causing issues?

Well, here in Florida, another superhero is hard at work… Handyman!

Fighter of grime. Tamer of wild lawns and landscaping. Fixer of broken items. Yes, there’s nothing this brave mutant wouldn’t do around the house given enough time off from his day job.

Why, recently, his arch-nemesis, Old Cheap Dining Room Chair came to visit, splitting along a poorly constructed glue joint.

Just look at that! A potential posterior pincher if there ever was one. This had the potential to endanger all of the residents of Chez Iovino.

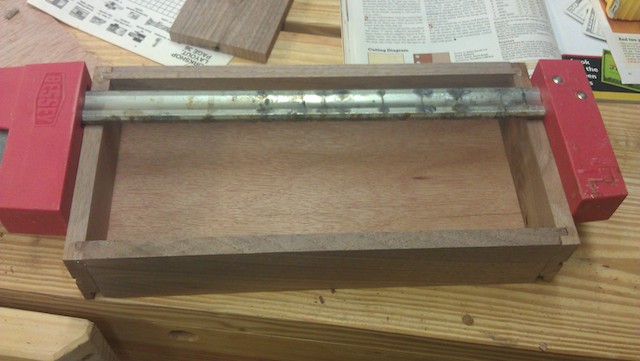

Fortunately, the call went out to Handyman, and, faster than paint can dry, he was on the scene with his necessary equipment. Just as important as the Lariat of Truth or the Batarang, Handyman reached into his bag of tricks to find the Gorilla Glue of strength and the Bessey Clamps of power!

Pow! Bang! Ooof! Before Cheap Chair knew what hit him, Handyman had squeezed a bead of glue into the split and spread it with a shim, evenly coating both sides of the seat. Knowing that the end was near, Cheap Chair tried to spit out all of the glue that Handyman used, but to no avail.

Once the Clamps of Power were applied, it was all over but the crying. Cheap Chair caved under the pressure, and the split was fixed, promising pinch-free sitting for years to come.

While citizens were able to see Handyman in action, he disappeared shortly afterward, unavailable for comment. Funny, that’s when my family found me, asleep on the couch… I had missed the whole thing…

But, I know, somewhere out there, Handyman waits for the next call, tools at the ready, when trouble rears its ugly head.