Bonjour!

Why is Tom writing en Francais today?

Well, if your calendar mentions it, you will notice that today is Bastille Day – the day the French commemorate the storming of the notorious prison named the Bastille – which also happened to contain quite a large stash of gunpowder. It was this day when the three estates unified and the French citizens started down that long road to today’s republic.

But, that’s not what I want to write about. I actually want to let you know about a large project I just started. It’s actually a big bank of cabinets that I’m building together with a friend from the Woodworker’s Website Association.

You see, Paul lives in a really sweet house built in the 1940s just a few miles from where I live. Over the years, as with many homes in Florida, the home was added to. One of the largest parts of the addition was the enclosure of a large outdoor patio. In this room, he and his wife have created a lovely living room with a comfortable seating area and a bit of a home office.

But, Paul wants more. So, he asked if I could help him build a home office area in this room. A number of cabinets with drawers and doors for the lowers and a pair of uppers to serve as bookshelves. He sketched out the design, and I figured out how many of which parts we needed for the cabinets. We were building the cabinets just as Norm Abram did in his nine-part opus on building kitchen cabinets.

And then he ordered the materials. Last week, the stuff arrived. A dozen sheets of prefinished and cherry ply. A box of hardware he ordered online. A few boxes of screws. And one of these…

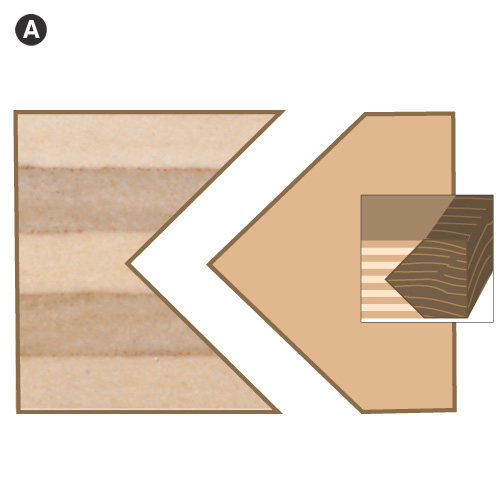

Yes, he brought over a Festool track saw. Perhaps you have heard about these saws and the hype that goes along with them. Every word of it is true. The saw cuts beautifully, leaving a very smooth cut edge in its path that rivals what I can get on my table saw. What I liked most about the saw was that we could flip those large sheets of plywood up onto the workbench resting on a few sacrificial strips of particleboard, mark and cut away. No need to hoist and balance large full sheets on the table saw or cut and then recut rough edges…

It took two five-hour days, but we ended up making all of the cuts for the boxes. We even had a few miscuts that ended in the boo boo pile. It was hot work in my Florida workshop, but we got all of the cuts done and dadoes and rabbets milled. Now, I am spending a few hours every night after work putting the boxes together with screws and glue, and things seem to be progressing quite nicely.

Once the boxes are complete, we will take them up the road to Paul’s house where we will build a base frame, install and face frame the cabinets in place.

Believe me, I will keep you updated on this very ambitious project as we progress.

Now, what about the French lesson at the start of the article? Well, I decided that today would be a great day to reenact the scenes of the French citizens emerging from behind their barricades to storm the Bastille. Standing in for the barricades are the cabinet boxes. Look, I know it’s a reach, but sometimes ya gotta do what you gotta do to keep it topical.

No, I’m not wearing the tricolor cockade or flying the banner of the French Republic, but I am hoisting a glass of Pinot Noir as my salute to the viniferous contributions of la République Française.