I can’t even begin to tell you how much I love movies starring the late, great Rodney Dangerfield. Caddyshack. Back to School. Easy Money. This guy was comic gold, and the movies he was in are still timeless classics.

He is well known for his self-deprecating sense of humor. Basically, the guy got no respect. How bad?

- When I was a kid I got no respect. The time I was kidnapped, and the kidnappers sent my parents a note they said, “We want five thousand dollars or you’ll see your kid again.”

- I asked my old man if I could go ice-skating on the lake. He told me, “Wait til it gets warmer.”

- Once when I was lost I saw a policeman and asked him to help me find my parents. I said to him, “Do you think we’ll ever find them?” He said, “I don’t know kid. There are so many places they can hide.”

At that, he would adjust his tie, and keep the one-liners coming.

The reason I bring up Rodney is that there are some tools in my shop that get no respect, but boy, do I love them anyway.

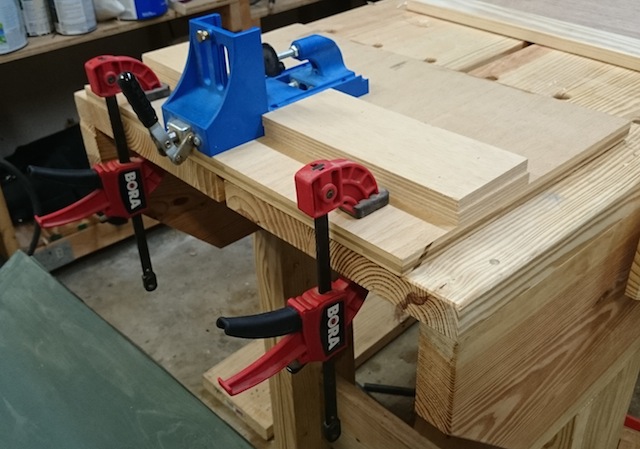

These quick action trigger clamps are the bomb. My favorites are these babies from Bora, and they are just about some of the handiest things to have around the shop.

Now, they aren’t long enough to glue up huge panels, but that’s OK, because there are tons of times when I wish I could have a third (or fourth or even fifth) hand in the shop, and they fill the bill nicely.

For instance, when I assemble projects (after my misfortunes on getting things square) I use some assembly squares to help keep things at 90 degrees. There’s no easier way to make this happen than to use these little guys to grab the square and hold everything true until things are joined properly.

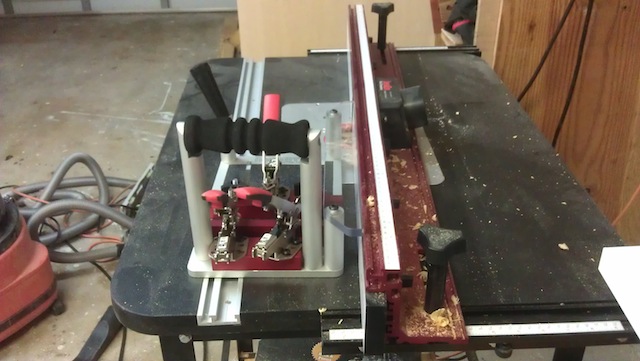

Another great time to use these babies is when I am holding tools down to the bench. Whether it’s the combo belt/spindle sander or the Kreg pocket hole jig, securing the tool to the bench really helps eliminate one potential problem of having the tool walk on me. These honeys grab nicely, and allow me to focus on getting the work done, rather than trying to manage the work and the tool.

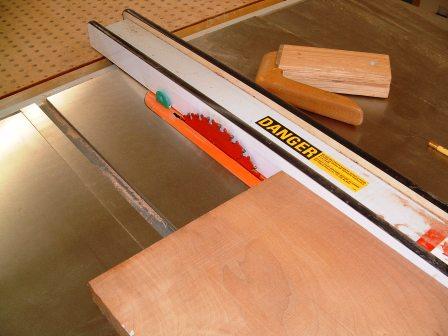

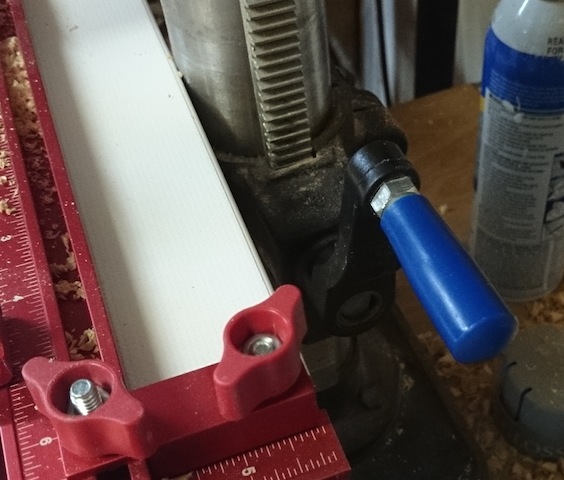

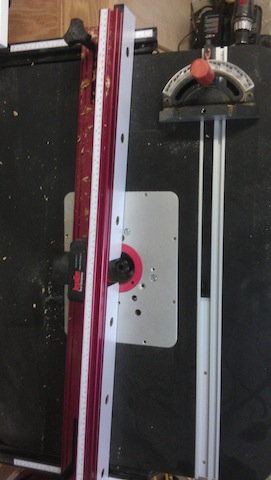

And, when it comes to setting up stops on tools like my miter bench, these sucker shine. Once I get the right measurement, I can break out the stop that I use (yes, I understand that’s not Cal Ripken) and clamp the stop to the miter table’s fence. This way, I can get accurate cuts without exposing my hands to the dangers of the whirly, spinny, toothy thing…. I can use these on all types of jigs for the miter saw, band saw, router table, table saw or anything else that can eat fingers.

Sure, the don’t get a lot of respect, but, hey, they definitely earn their keep in my shop!