My family loves to watch movies. We subscribe to Netflix and get the movies sent to us, or we’ll watch them on the kids’ Play Station. Man, that’s a convenient way to watch movies!

And, while we love to watch movies, getting out to them can be a real trick. I think most of our local theaters now offer easy financing at the snack counter. When they don’t post the price of the popcorn-and-soda snack deals, well – as they say – if you have to ask the price, you probably can’t afford it anyway.

So, when we go out to see a movie, we have to choose our selections carefully. And, there was a stretch back in 2005 when the only good movies out were animated. Hoodwinked was a great one. So was one of the Shrek franchise films. But, the one that we liked the most was Wallace and Gromit and the curse of the Ware-Rabbit. Now, it sounds kinda hokey, but if you haven’t seen it, it’s definitely worth a watch.

I don’t want to give away the entire plot, but it does involve a giant veggie-stealing rabbit and the hijinks that go along with putting an end to the terror plaguing the contestants in the annual Giant Vegetable competition.

Sometimes in woodworking, we need to look to rabbits as well. Or, is that rabbets? A quality rabbeting bit can be a big time player in your arsenal.

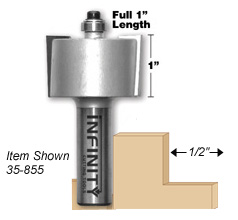

Me, I’m happy to have a big rabbeting bit I picked up from Infinity tools. This baby is a real brute. It has a half-inch shank and a two-inch diameter slug of metal with a full one-inch depth of cut.

Why such a massive bit? Options, my friend. With the rabbeting bearing kit, you can take this massive bit from an 11/16” cut all the way down to a flush trim. Of course, for a very deep rabbet, you’d want to do that in steps as to not get all kinds of tear out. For that, you may want to lower the bit to the proper depth over a few passes, as opposed to changing the size of the bearings.

The one-inch cutting surface is pretty cool as well, making flush cutting easier. And, if you want identical parts for a project, template routing makes it easier to get the accuracy you want.

The thick carbide tips lean forward (positive shear angle) so you get fine wood shavings. Yes, you get shavings, not dust or chips with this bit.

I have found mine to be useful for rabbeting the backs of cabinets to allow for a back to be mounted. And, when paired with a router based tenon cutting jig, you can make mortise and tenon projects easily.

Those are just a few uses for a quality rabbeting bit, and I’m sure once you get some experience using one, you’ll be able to pull a few woodworking rabbits out of your own hat.