I was just out in the shop applying another coat of poly on the stairstepped bookcases when it hit me.

Woodworking, for the most part, is a solitary hobby. Sure, if you work in a commercial woodworking shop, there are folks there, and if you go to a woodworking school, there are folks there as well. And, if you are blessed to have family members who share your interest in the craft… well… good for you!

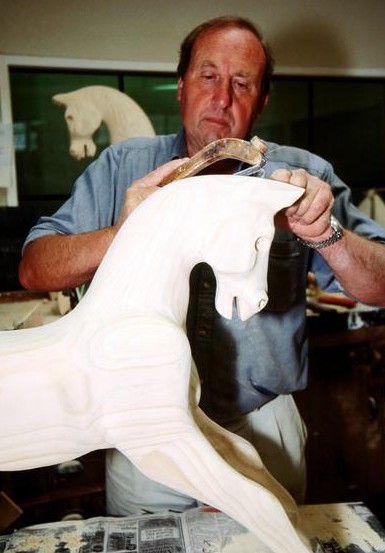

But, more often than not, we are at our benches plying our craft. Planing boards. Cutting joints. Messing up, then hiding the evidence.

It’s not like golf, where you get at least a foursome together to hit the links. Plus, there are lots of tournaments to go to.

Fishing? It’s always best to drink a few beers with friends while you drown a few worms.

Running? I think there may be a 5K race every single temperate weekend within a 50 mile radius of your home.

But, woodworking can be a lonely pastime, even for those of us who are very active in the Internet woodworking community. No matter how many tweets, Facebook status updates or Google+ postings, we’re still out there in our shops plugging away all by ourselves.

That’s why I relish the opportunity to get together with other woodworkers. Every spring, the Woodworking Show comes to the Tampa Fairgrounds, and I always get a kick out of attending that. But, the Woodworking Show travels around the country, so I don’t see too many folks from outside the state of Florida when the show gets there. Florida woodworkers are awesome, but we share so many of the same challenges. For instance, there are only so many gosh-my-shop-is-sweltering-in-July stories you can swap before everyone nods their head in agreement.

That’s why I look forward to the Woodworking in America conference each year. This year’s event is taking place in Covington, Kentucky, and it draws woodworkers from around the country. As with the Woodworking Shows, there will be a vast array of woodworking tool manufacturers and dealers. Some slated to be in attendance include Lee Valley, Lie Nielsen, Benchcrafted… the works!

And, these aren’t just booths staffed by a disinterested temp employee – no sir. You have a question about a replacement iron for your classic hand plane? Just ask Ron Hock what you need to look for. He’ll be there. Joel Moscowitz from Tools for Working Wood can talk your ear off about hand saw sharpening. Maybe Konrad Sauer can talk you into giving one of his hand planes a spin.

The thing I enjoy the most – of course – is the camaraderie with the other woodworkers and their experiences from around the country. Just think – Matt Gradwhol is coming all the way from Seattle to attend, and I’m coming up from the Tampa Bay area. You would be hard pressed to find two areas much farther apart in the continental United States, but we’ll be rubbing shoulders (and nibbling on Nuncake, I hope) there. The woodworkers come from big cities and small hamlets across the country. They come with expertise in power and hand tools. They come with all levels of experience and areas of specialty.

Oh, yes, they come.

And we get to kick back and talk sawdust, eat good food and enjoy each others’ company. .

I plan on being in the marketplace on Friday and Saturday, helping Mike Siemsen with the Hand Tool Olympics and participating as well. I’ll be interviewing many of the folks there for future articles. I’ll be dropping my card off at a few booths – hopefully landing a few more sponsors for the old blog.

And, when I get back to my shop, I’ll be re energized and ready to build some more!