Yes, it’s true. I had a kickback on my table saw last week.

Even after all of the safety posts I have written, it still happened. It wasn’t serious enough to require me to go to the hospital or seek other emergency medical help. Thank goodness.

I got a bad bruise to the tip of my left index finger and a gash on the inside of my forearm about four inches down from my elbow. I’m nearly recovered from this mishap.

However, it did serve as a gigantic wake-up call for me to review my attitude about safely operating the table saw. Here’s a list of what contributed to the accident.

- It was the proverbial ‘last cut of the night’

- I was feeling tired

- I was frustrated because I was following a plan that gave incorrect dimensions for a part… I had to saw, edge and thickness another piece of wood to work with a larger blank – and it was curly maple… not something I want to waste.

- I thought the thin material (1/4″ thick) wouldn’t hurt if it did kick back

- I was crosscutting a board about 3″ wide by 12″ long using the rip fence to gauge the distance… believing it would be more ‘ accurate’ and ‘easier’ to deploy.

- My wife had just walked in to talk to me, so I took my eyes off the work.

As you can see, there were quite a few contributing factors to this accident. For me to ensure my safety, I am going to have to help set the tone in my shop.

Of course, I’m going to have to start to recognize when I do get feeling tired, frustrated or distracted and learn to walk away from the power tool. It’s better to do something mundane like sharpening a plane iron than packing my fingers in an ice-filled Ziplock bag for a trip to the hospital.

But, I have to also use the proper jig to help ensure my safety. Crosscutting using the rip fence is dumb. It’s stupid. It’s something I know better than to do. However, I did it anyway, even though I have a $159 Osborne EB-3 miter gauge and a large panel cutting jig maybe a dozen steps away from the saw.

Why didn’t I use them?

The sled is just too heavy. It’s a monster jig I built to crosscut up to 18″ wide panels. Great for that application, too much to heft to the saw for small cuts.

The Osborne is sweet, but for small work, it gets kind of awkward, trying to balance a small piece against it. Besides, it doesn’t allow me the option of clamping the work down to the table so I can move my hands out of the way.

So, I set my mind to build a small, maneuverable crosscutting sled that is lightweight, accurate and allows for clamping. The problem I ran into when looking for one on the Internet is that the plans fall into one of two camps.

There are those that are just too darned simple. A runner for the miter slot, a back or front fence and a sheet of plywood. These, like the famous one found in Norm Abram’s shop, are great for cutting square edges on larger panels, but fall down on the job when cutting smaller stock. Besides, these typically just ride on one side of the blade, leaving the ‘offcut’ side unsupported. I needed something that will bridge the saw blade, keeping the workpiece securely supported on both sides.

Others look like wooden Swiss Army Knives. They can miter, tenon, crosscut, slice, dice, julienne and make mountains of cole slaw based on how they are set up. Crisscrossed with feet of T-Track, hold down knobs and other devices, they are only slightly more complicated than the entire Apollo Moon Landing program, and can take several nights of detailed construction to become reality. This, of course, brings us back to the weight problem. If they are too heavy, I can see myself at a later date wondering if I really need to get the sled off the shelf…

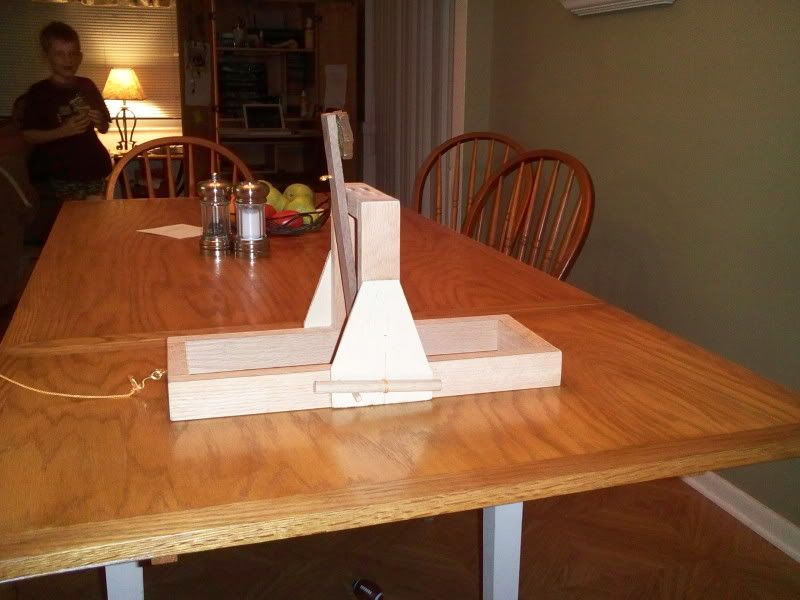

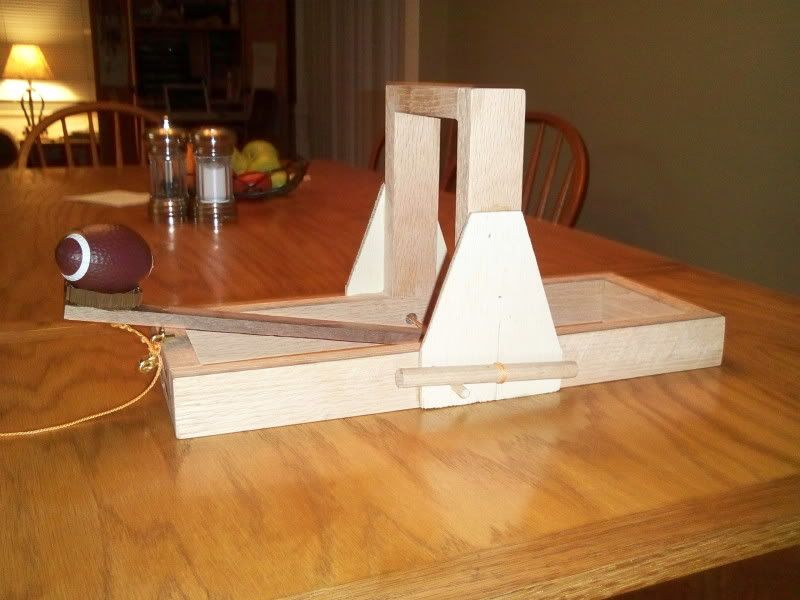

This is what I came up with. It’s rather simple to build and it offers me a lightweight jig with excellent accuracy. As with most crosscut sleds, the heart of the system rests with the miter slot runners. I milled these out of a straight clear piece of maple. One in each slot, and they fit perfectly.

The base of the sled is a piece of 1/2″ MDF 16″ wide by 24″ long. No, may not suffice for large workpieces, but that’s not the purpose – this baby is set up to handle small work. I cut it square on the table saw, butted it against the rip fence and laid it on top of the glued runners. A few brads held it the assembly in place until I could flip the board over to mount screws.

The front fence is a 3 1/2″ tall piece of 3/4″ cabinet grade ply. It’s that high so the blade won’t cut through it, leaving me with two sleds.. something I’m not looking for. It was glued and screwed to the piece from underneath. Once I did that, I pushed the sled through the blade until it was close to the back of the MDF sheet – not all the way through.

The back fence is two pieces of 3 1/2″ tall cabinet grade ply glued and bradded together to give me a piece 1 1/2″ thick. My initial plans were to install a T-Track to serve as a base for a hold-down clamp, but I held off for now. That will be a later edition if I want the convenience. Once I got the back fence squared to the blade, I glued and screwed it into place and pushed the sled through the blade.

I also dug through the scrap bucket and came up with a few scraps of southern yellow pine to serve as hold downs. Now, when I want to cut a small piece, I can set it in place, using the saw kerf to accurately mark where the blade will cut. I can then clamp one of these scrap SYP pieces directly down on the board to be cut right at the kerf line. This way, I can ensure the wood won’t move, and I can keep my hands safely away from the blade.

My first couple of cuts with the sled were dead-on at 90 degrees. The pieces didn’t move, and I was very happy to have my fingers safely out of the way.

Improved accuracy AND safety? For the handful of scraps and screws I used, it was well worth the cost.