Oh, how I hated doing chores while I was growing up. Weed the flower beds. Shovel snow. Clean up the dishes after dinner.

And, make your bed. It was a chore I couldn’t understand why it was so important. I mean, yes, my dad was a Marine, and my mom loved to keep a neat house, but it seemed like such a waste of time, neatly folding and straightening out the sheets and blankets only to mess them up again later when I tucked in for the night. But, it was a big deal, and even though I couldn’t understand it, I just knew it was trouble if I didn’t take care of it.

Well, Mom and Dad, I’m making my bed. From scratch now. Yes, I’m building a new bed for Rhonda and me, and it’s about time. The original bed we bought when we first got married had served us well. It just was missing one critical thing in our basementless Florida home – storage. So, I set about to build something with a little storage that would be something a little stylish.

It all started, as you might imagine, with getting some supplies at our local home improvement center. I had the folks there cut the sheets down to the basic sizes so they would be easier to get home. And, you bet, it made carrying this stuff a whole lot easier.

Once I had the goodies in the shop, it was a simple matter of carefully marking where things had to be cut and where joinery had to be plowed out.

I turned to my router for most of the dadoes, since the pieces were very large. The rule of thumb is if it’s small enough, bring it to the tool (plow out those dadoes on the table saw), if it’s too large, bring the tool to the wood (routers).

With the dadoes plowed and pieces cut, it was a snap to move to the next step, which is a great tip I remember from Norm Abrams’ master opus when he built his kitchen cabinets – drill a pilot hole through the dadoes on the cut side, so later, when you go to assemble the pieces, you know exactly where to put the screws.

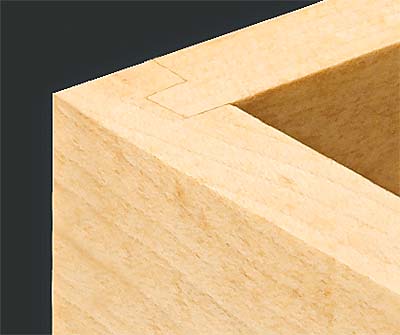

With the pilots drilled, it was time to assemble. I grabbed my glue bottle and a huge box of screws and set to work. The pieces needed only the slightest encouragement to drop into the dadoes, which meant I had done a good job getting the joints to fit tightly.

The screws were there to ensure that the piece would remain tight throughout its lifetime. With a whole lot of effort, and some skinned knuckles, I managed to get the cabinets together.

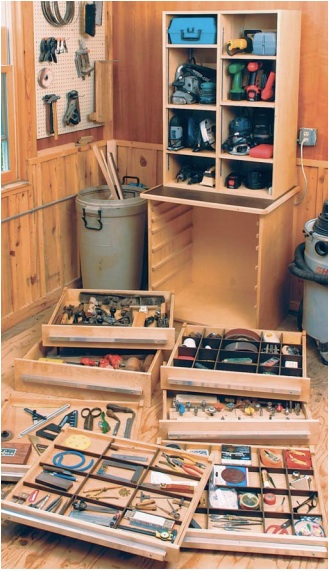

Since a queen size mattress is 60 inches wide, I opted to build the piece as two cabinet halves and bolted them together. This way, Rhonda has a set of three drawers on her side of the bed, and I have a set on mine. It also allowed me to move each half into place, lessening the weight and making them more maneuverable as I threaded my way through the living room into the bedroom.

Once in place, I bolted the two halves together and put the mattress on top. That was plenty of work for one day. I figured I could work on building the head and footboards and drawers and move them into place as they are finished, making more room in my shop to move around.

As far as the old bed goes, well, our neighbor’s daughter is moving out to her own place soon, so I was thinking we could offer her the headboard, footboard, frame and box spring to her so she can set up her bedroom. No sense letting it go to waste.