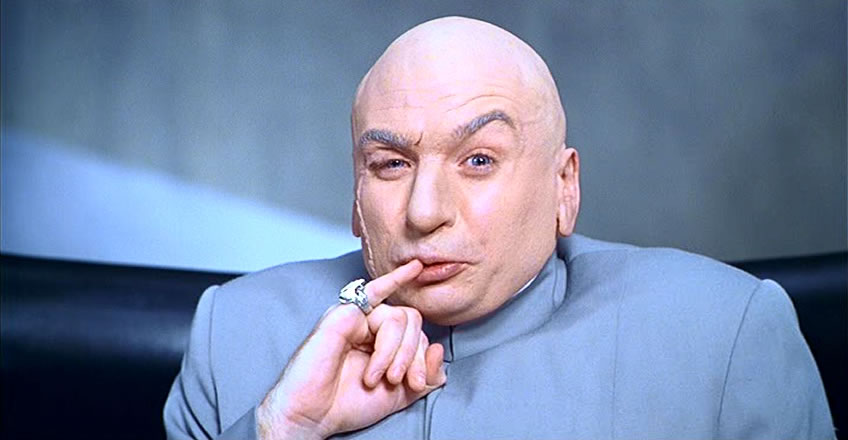

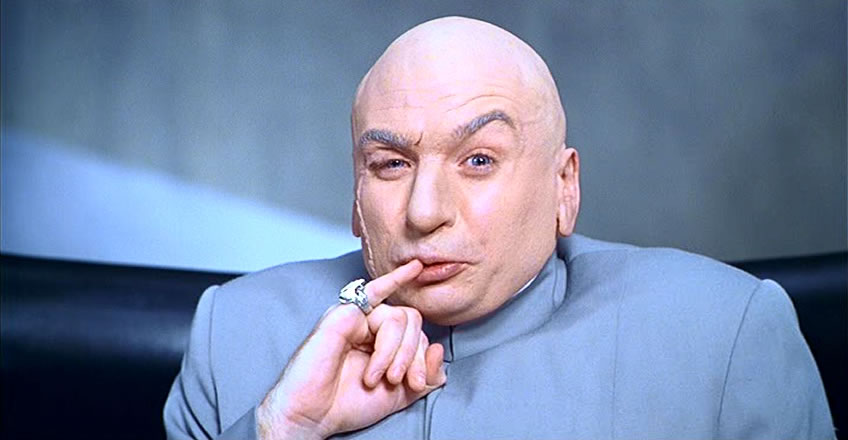

As a fan of the James Bond series of movies (Goldfinger was my favorite movie in the franchise), I was thoroughly amused by Austin Powers, the Mike Myers spoof of the classic spy films.

One of the most memorable scenes happened after the hero Austin Powers and his partner Vanessa Kensington were captured by Dr. Evil’s minions and brought to an elaborate dinner party in Dr. Evil’s lair. In a nod to the the first movie in the Bond series, 1962’s Dr. No, Austin and Vanessa, clad in their quasi-futuristic costumes, are sat between Dr. Evil’s henchmen while Dr. Evil explains in great detail his fiendish plot to destroy the world if his demands are not met.

That’s when Dr. Evil’s son Scott enters the room from his bedroom. Dr. Evil, in a grand gesture, introduces Scott to Austin by saying, “Scott, meet daddy’s nemesis, Austin Powers.” Scott, incredulously, asked, “And you’re feeding him?”

In my shop, there are few tools I have yet to at least have a working relationship with. Sometimes, the tracking on my band saw gets a little ‘drifty’. Sometimes, a few of my hand planes can be finicky. But, with a little bit of time and effort, I can get them to do what I need them to do.

Then there is this. My lock miter bit. This little router bit called to me at a woodworking show a few years back. The slick talking exhibitor showed how useful the joint is. How quick to cut. How easily the joint goes together. He cut joint after joint, winking to viewers as his smooth voice lured others over.

I had to answer the siren’s call. I dropped my money and took this miracle bit home with me anxious to make things happen.

Boy, did stuff happen. Some head scratching. Some grunts of frustration. Some cursing. And lots of wasted test boards. And, worst of all – a lot of wasted precious shop time.

I’ve used the so simple a child could do it ‘adjust the height until the boards match up’ method, with no success. This time, armed with the Groove Center made by Prazi, I was bound and determined to make things work out.

I followed the instructions to the letter, but still found myself scratching my head with yet another bad result. Now, I’m sure the problem with this bit is that there’s an id10t error going on somewhere in my setup. Maybe it’s because I’m not getting the accuracy I need in my router setup. Maybe it’s because I’m not using the tools properly. I’ve seen both the bit and the Groove Center work flawlessly in demos. I just can’t make it work in my shop.

I’m sure I could continue to fiddle with this bit again and again, and maybe after a few more hours of shop time, I might be able to make one of these joints work.

But, ya know what? The heck with it. I’ve given too much to this time vampire. For the love of Pete, I could just cut a basic miter joint and break out my biscuit jointer if I needed to reinforce it. Or, maybe set up for a Kehoe dovetail spline or just a basic spline reinforcement if I wanted – either through the joint or hidden within.

One thing is for certain.. using this bit has been one of the most frustrating experiences I have ever had in the workshop. I just might put this baby back into its case and set it somewhere in the back of my tool storage cabinet and keep it there for a very long time… I don’t think I’ll be feeding this one any more of my shop time.