I have to confess… I love milling lumber. It’s so cool to peel off a layer of rough wood to see what lies beneath. But I have grown tired of my Delta planer. It’s OK, and it has served me well for years, but its performance has been – how shall I put it – lousy.

It seems to work very well with straight-grained, thick hardwoods. It can plane those all day, leaving a bit of a divot at the rear, but better than satisfactory everywhere else. But, get that wood thin or figured and it’s Katie bar the door. I’ve seen rough board surfaces turn into moonscapes of tear out and snipe marks everywhere. Just awful.

There are plenty of tricks out there about how to reduce this nastiness. Build an extension board. Check. Take very light passes. Check. Moisten the top of the board before planing. Check. Push it through on an angle. Check. And, none of these tips worked. At all.

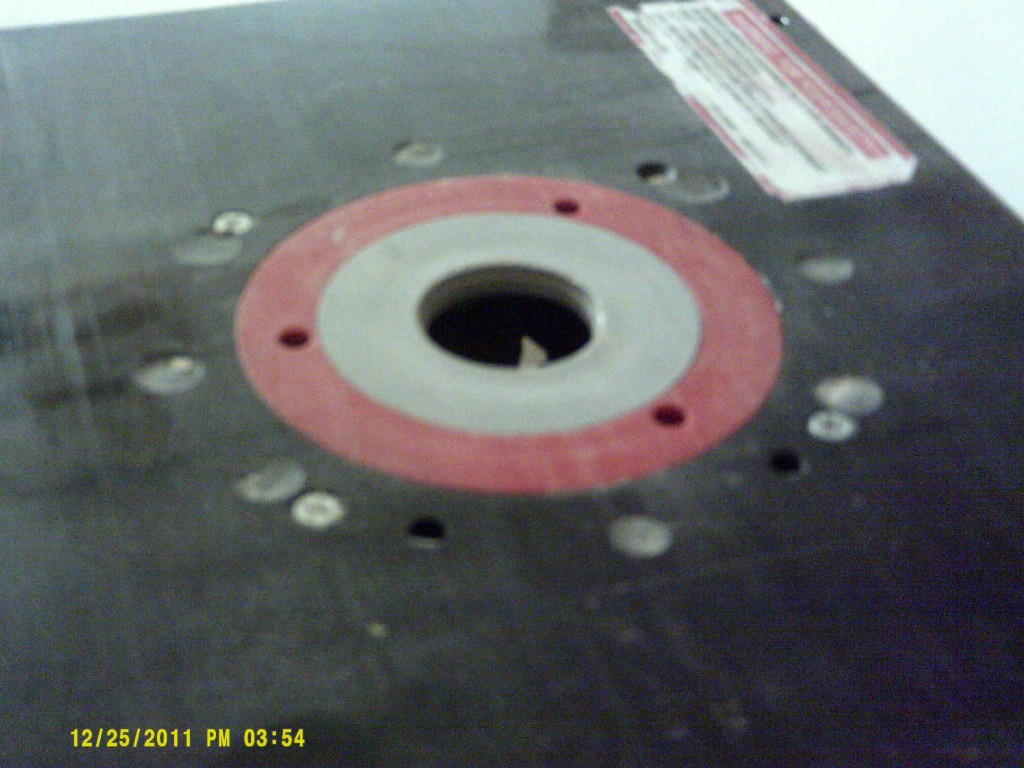

So, last night, when I got home from work, I decided the time was right to take the plunge. I grabbed up all the Home Depot gift cards I got for the holidays and trucked on down the road to big orange. There, I bought the latest and greatest Ridgid planer – the model R4330 thickness planer.

Why this model? Well, first of all, I’ve had a lot of success with Ridgid tools – my spindle sander, miter saw and table saw are all nice and orange. This model also has a three blade cutterhead – and, from what I read, that gives a better result than the two blade cutters. It has the Indicut control, which shows me when the cutterhead assembly contacts the board and how much material I’m taking off. Plus, I can’t get enough of the built-in dust collection. I hate shoveling the shavings after I plane boards with my Delta – they get everywhere.

I had fun loading it into my Corolla, and I hauled it to the shop with some help from my son Dominic. The assembly was very easy, consisting of putting together the dust collection shroud and the height adjustment handle. The fit and finish of the tool was very nice, and I loved the features such as on board tool storage for assembly and blade changes as well as a convenient cord wrap.

Sure, I should have read all of the directions carefully before I began, but DUDE, I needed to try it out! So, I plugged it in and took some curly maple I had resawn and attempted to plane on the Delta (Boy, was that a bad idea). I figured that the pieces may already be a total loss, so what was there to lose?

I set the cutterhead to where it just kissed the board’s top and turned the motor on. I carefully fed the board through, and it slid right under the knives. OK, maybe a little lower next time. And, I could hear the knives just graze the board’s rough top. Another pass, and more knife contact. Soon, I was removing the ugliness of the previous night’s attempt, and things were looking good. And, I mean REALLY good.

So good, in fact, that I believe that sanding these curly maple panels would ruin the very nice surface I put on them! I didn’t think it was possible to get this kind of smoothness straight from the planer, but wow, I was totally impressed. And, yes, that board is 1/4″ thick… with that kind of smooth surface on it. Unreal.

The planer does fold up into roughly the same sized footprint of the Delta, so stowage shouldn’t be an issue. With this new planer, I think I can get over my phobias and start looking forward to getting more use out of the tool.