OK, so I really need to figure something out in 2012. I mean, I’ve been woodworking since 1998, and I still have yet to get a straight answer on this.

Just how strong are certain woodworking joints?

I ask this because I am now on the last day of my winter break. Yes, I took my first week off since the holiday season of 2010-2011. And, this week, I had a little bit of time to kick my feet up and go through a box of back editions of woodworking magazines that a neighbor was looking to get rid of. I mean, a collection that stretched back to about 1997. Awesome old articles like the one I found in the July 2007 edition of Wood Magazine which was written shortly after the release of the Festool Domino.

Bob Hunter and Jeff Mertz compared the strength of four common ‘loose dowel’ type joints – The Beadlock, dowels, biscuits and the Domino – versus a classic mortise with a 1″ tenon. No surprise, the traditional joint totally kicked the competition’s butt in the shear and pull apart tests. But, here’s where things get a little whacky.

You see, Bob and Jeff found that – ta da – dowels did better than the Beadlock or the Dominos.

Intriguing, because the folks at Fine Woodworking in the January/February 2009 edition said that the Beadlock finished first, ahead of the dowels and the Domino. The also found a tremendous difference between a floating tenon and the Domino – finding a shop-made floating tenon to be two and a half times stronger than the competition. But, I’ve seen so many people point to the Domino and tell me that they would be more than happy to replace the traditional mortise and tenon joints in a chair with a Domino… but never with dowels…

Which makes you wonder how the folks at Popular Science found that dowels are equal to mortise and tenon joints in their October 1979 edition. Unless you consider the folks over at Woodgear, who definitively proved that mortise and tenon joints are stronger than dowel joints.

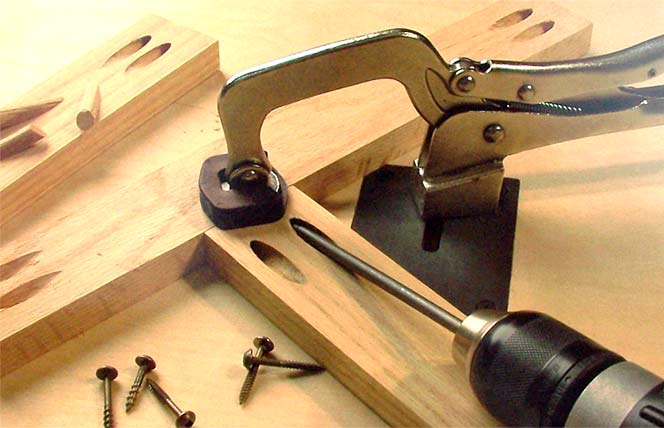

Of course, you could just believe the claims being made that pocket hole joinery is 35% stronger than a mortise and tenon when it comes to shear strength.

I mean, come on. I know wood is a natural material, so there will be some variation in strength. And, I’m sure that most of these tests are conducted in shop – not laboratory – conditions. But, I watch Mythbusters, and I think I know something about scientific method. Or, at least how five TV savvy geeks use it. But, to get some of these out-there results… I’m not sure.

So, you know what I’m gonna do? I’m going to learn how to use my new Mortise Pal jig. And, I’m going to break out my Joint Genie doweling jig. And, I may even use a biscuit or two and a handful of pocket screws.. and I’m just gonna build this year.

There. My first executive decision of 2012.

No kidding. I guess the differences are sampling group and the range of difference (is a dowel 200% stronger or 50%?) You would figure that this would be settled by now. Also, how do these test loads compare to normal real-life conditions? How critical is the woodworker? Does one system only work if executed perfectly, or does another one work better if it’s a little sloppy?

Jonathan

================================

GO FOR IT TOM!! I can’t wait to see your results!

I have a feeling that if you use a good wood glue with each type of joint it will be a very tough call.

Also, appearance and the individual project should come into play of course. How much strength does a jewelry box need compared to a rocking chair? 🙂

Rog

I have used biscuits in situations where mortise and tenon joints would have also been used and I have not yet had a failure. My point is that certain types of joinery are very effective in the right conditions. I use pocket screws only in situations where stresses are minimal. The info you mentioned about dowels is interesting. Dowels have become boring I think, not as sexy as other types of joinery. I used them to join legs of my coffee table to the aprons. Glad to see in your post they perform so well.

Jeff

It’s simple, Tom: every joint is either:

a) strong enough; or

b) not strong enough.

Chris, keeping it real.

Very Zen, Chris…

Tom.

Sam Malooff used a ton of screws … nothing wrong with that. I like the simplicity of the Domino and now that you mention it … will use Domino plus pocket screws and stuff should never come apart.

Take care.

Great Post.

Bobby

PS … I am about to have some Norton Select Malbec … very good indeed.

Good for you!

I was lucky enough to work on a drill press review for Fine Woodworking Magazine about 10 years ago. Unfortunately at the end of all the testing we sent our reviews to the magazine only to find they skewed the results to fit their agenda!!! I thought I was doing something good for the woodworking world only to find the information manipulated. They chose the Rigid drill press where in actuality the General International did the best in it’s price range and even better is the General built in Canada if you can afford it.

Roger and Jeff made some excellent points. Through experience, pick a joint appropriate for the application. Select a premium glue that is right for the joint. Build to exceed the minimum specification, rather than barely good enough. Give each step the time and attention as though it is supposed to last your grandchild’s lifetime.

By doing the work of a craftsman, you contribute to the value of the trade, and the people who make up such a time-honored society…