Remember the 2×4 challenge earlier this year? You know, the one where I built a pirate chest with a domed lid?

Well, you will never guess what the St. Petersburg Woodcrafter’s Guild is up to next… It’s the annual green challenge, where the majority of your materials need to be reused from another source. Last year, I didn’t get involved in the challenge because I ran out of time (oops!) before the deadline. But, this year, there was a convergence that kicked me in the rear.

First, at Woodworking in America, I saw a great project built by Chris Schwarz of the Lost Art Press. He recently build a Dutch Tool Chest for Popular Woodworking magazine, and something about that project really caught my interest. The size, the shape, the slanted lid, the storage and the blue milk paint really tripped my trigger.

First, at Woodworking in America, I saw a great project built by Chris Schwarz of the Lost Art Press. He recently build a Dutch Tool Chest for Popular Woodworking magazine, and something about that project really caught my interest. The size, the shape, the slanted lid, the storage and the blue milk paint really tripped my trigger.

The other part has to do with the rebounding real estate market. For the past six years, home sales have been pretty darned terrible here in Florida. Some homes on my block sat abandoned, while others were rented out. As the economy has recovered, suddenly there is a flurry of sales in the neighborhood. And, with that comes the inevitable renovations. And, every week as I go around the neighborhood, I see piles of vanities, kitchen cabinets and other debris that has been thrown out.

That’s where I found some sweet, good old no. 2 common pine used as shelves. Since the tool chest has to be both strong and light, Chris built his out of pine, and I couldn’t pass on the opportunity.

The plan can be found in the October edition of Popular Woodworking, and it’s very simple. Sure, I broke with tradition and didn’t cut my joints with hand tools, but the final piece will be function just as if it had been.

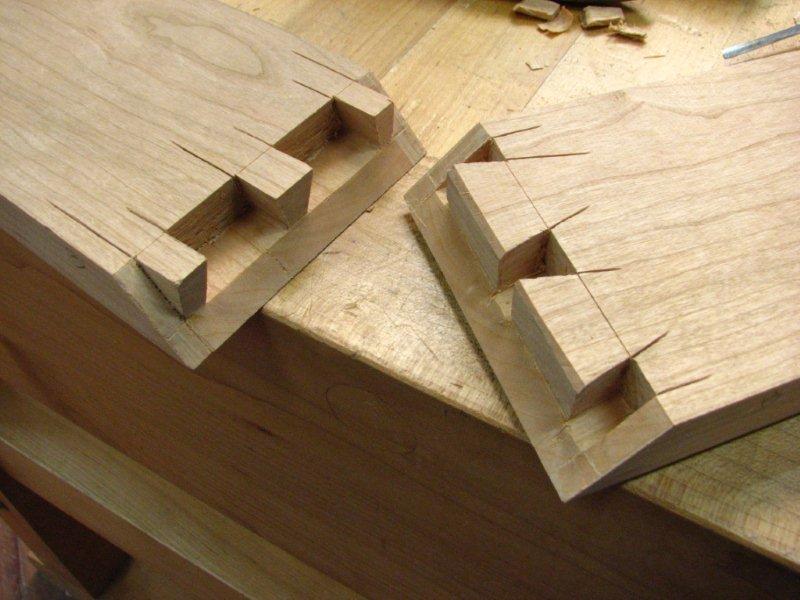

The sides of the case are dovetailed to the bottom, providing some tremendous strength for the assembly. A middle shelf is dadoed and screwed into the sides to help keep the case square and to provide a location for the back and front to be attached to the case, providing more strength. My plan is to use plugs to hide the screw heads from view once the piece is complete. Oh, and when I cover it in a coat of blue milk paint, I hope those plugs just disappear…

The sides of the case are dovetailed to the bottom, providing some tremendous strength for the assembly. A middle shelf is dadoed and screwed into the sides to help keep the case square and to provide a location for the back and front to be attached to the case, providing more strength. My plan is to use plugs to hide the screw heads from view once the piece is complete. Oh, and when I cover it in a coat of blue milk paint, I hope those plugs just disappear…

Of course, I have a long way to go with the case, but I hope to have it ready to go for our next guild meeting. After that, wouldn’t it be great to stash those nice hand tools in a protective, portable and stylish chest out in my shop?

However, as I load my hand tools into the chest, it struck me that I didn’t really have all of my tools very well organized. Yeah, they were in drawers, but they were all jumbled together, making it kind of a mess.

However, as I load my hand tools into the chest, it struck me that I didn’t really have all of my tools very well organized. Yeah, they were in drawers, but they were all jumbled together, making it kind of a mess.