Theobroma Cacao. Food of the gods.

Yes, that’s what the scientific name for cocoa is – and it couldn’t be a more appropriate name. Native to Central America, the Aztecs fell in love with cocoa at first taste. The conquistadors who went on to discover the new world – and lay waste to the native cultures – were just as intrigued, and brought cocoa back to Europe where it eventually was processed and made into chocolate.

Yes, that’s what the scientific name for cocoa is – and it couldn’t be a more appropriate name. Native to Central America, the Aztecs fell in love with cocoa at first taste. The conquistadors who went on to discover the new world – and lay waste to the native cultures – were just as intrigued, and brought cocoa back to Europe where it eventually was processed and made into chocolate.

Today’s species spotlight isn’t on this plant, but instead it is on a dark reddish brown Central American wood that looks just about as delicious as chocolate.

Today’s species spotlight isn’t on this plant, but instead it is on a dark reddish brown Central American wood that looks just about as delicious as chocolate.

Cocobolo grows primarily along the Pacific coast of Central America, from Panama to southwestern Mexico. The trees can grow from 50 to 60 feet tall with a diameter of about 24 inches.

The heartwood is a gorgeous, dark brown red with an irregular grain, which can sometimes be interlocked. Cocobolo is also a very stable wood which rarely checks or moves while drying. It works very well, taking crisp details and finishing to a high polish. The wood is also very hard and dense, which makes it an excellent tonewood for musical instruments.

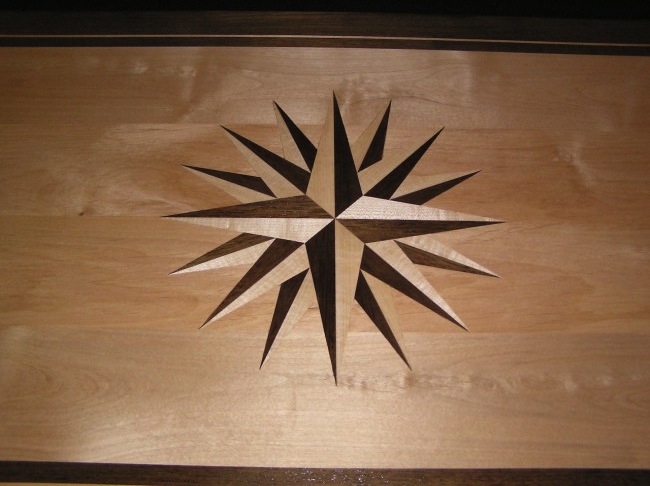

Cocobolo also shines as an accent wood for high end projects, such as knife scales, furniture inlays, pool cues and the like. When paired with a contrasting wood, it can really make a striking appearance.

Cocobolo also shines as an accent wood for high end projects, such as knife scales, furniture inlays, pool cues and the like. When paired with a contrasting wood, it can really make a striking appearance.

As with many tropical woods, cocobolo is an oily wood, which can create issues while gluing. Wiping the mating surfaces with acetone before applying glue can help improve your success.

The oil can also make for trouble when it comes to applying finishes. So, you can go one of two routes. You can burnish the final project by sanding down to a very high grit. The finer the grit, the more lustrous the finish will be. Another option would be to use a sealcoat of shellac, which will isolate the oils from the finish layers you want to lay down.

The oil can also make for trouble when it comes to applying finishes. So, you can go one of two routes. You can burnish the final project by sanding down to a very high grit. The finer the grit, the more lustrous the finish will be. Another option would be to use a sealcoat of shellac, which will isolate the oils from the finish layers you want to lay down.

Also, that oil can cause rashes or other allergic reactions, so be sure to use good dust collection, a particle mask and preferably long sleeves while working with it.

As you might imagine, with its limited growing area and striking beauty, cocobolo has been overharvested in the past, leaving the species as threatened. That’s why it is important to check with your supplier to ensure the trees come from managed areas and responsibly harvested.

As you might imagine, with its limited growing area and striking beauty, cocobolo has been overharvested in the past, leaving the species as threatened. That’s why it is important to check with your supplier to ensure the trees come from managed areas and responsibly harvested.

So, the next time you want to put some tasty details on your woodworking projects, you just might to check out cocobolo, which could easily be named the wood of the gods…

Inlays can be very simple or uber complicated, with multiple species intertwined in decorative designs.

Inlays can be very simple or uber complicated, with multiple species intertwined in decorative designs.