Boy, was I a mess late last week. It had nothing to do with the Modern Woodworkers Association podcast, which did end a little later than normal. And, it had nothing to do with work, which has become crazy this time of the year.

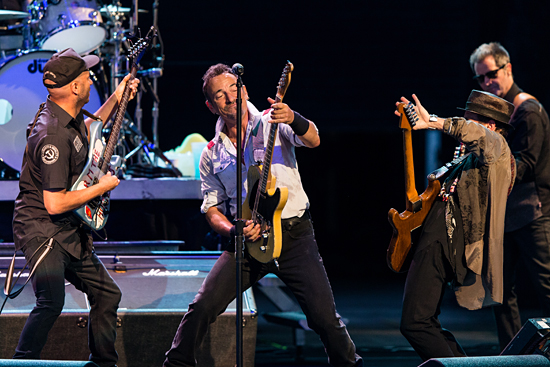

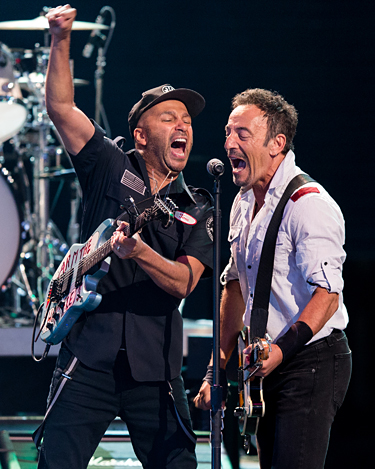

No, it had to do with a little concert I went to see on Thursday night. There was this show by this guy you might have heard of – Bruce Springsteen – that I went to see on Thursday night. Now, it’s been a few years since I last saw him (Born in the USA tour, 1985, on the floor of Giant’s Stadium in East Rutherford, New Jersey), and I can distinctly remember that his show went on for a long time.

This show was no exception…

THREE hours after Bruce and the E Street Band hit the stage, they started their encores. Without taking a break. The musicians are machines, still able to crank out the tunes nearly 30 years later.

Which, of course, led me to make some woodworking observations based on what I had learned from The Boss.

- Don’t be afraid to change your tune. Bruce turned out rockers for years, but took a risk by recording folk tunes in his Seeger Sessions album. While a totally different genre of music, those songs blended flawlessly into the show, adding a ton to what was already a great show. How many times do we build the same kind of projects because we don’t want to get out of our comfort zone? Reach out. Try those projects you have always wanted to. You just might be surprised with what you can do.

- Keep your circle of friends wide. Ever since his original album – Greetings from Asbury Park in 1972 – Bruce has performed with a group of musicians know as the E Street Band. Through the years, the numbers and members of this band have changed, and has evolved into a full-on stage production including a full horn section. By keeping your woodworking circles wide open, you can meet other woodworkers who can bring their special talents to your woodworking repertoire. Perhaps someone had a lathe and can turn a component for a project for you, or a big bandsaw that can resaw a special board for you.

Keep doing what you enjoy. It was 29 years since I last saw him, and I know it has been 41 years since his first album hit the scene. Still, you can tell that Bruce brings the energy to the show and enjoys himself tremendously. He makes it seem as if it’s not even work. As long as I can get out into the shop and enjoy what I am doing, I can picture myself doing this for years to come.

Keep doing what you enjoy. It was 29 years since I last saw him, and I know it has been 41 years since his first album hit the scene. Still, you can tell that Bruce brings the energy to the show and enjoys himself tremendously. He makes it seem as if it’s not even work. As long as I can get out into the shop and enjoy what I am doing, I can picture myself doing this for years to come.

Fortunately, I had a weekend to catch up on my sleep so I can go to work this week. But, when I do, I will be listening to The Boss on my little office radio.