You can learn a lot about people when you are shopping for a home. While it’s been about a dozen years since my wife and I bought our house, the memories of walking into people’s homes on our short list still live vividly in my mind.

There was the smell of the home of an avid cat lover, the sight of burnt orange and avocado appliances of people who chose not to update their 1970’s kitchens and the strange perceptions of being in a home where the owner had hung several overhead lights for decoration. Yes, that’s right. Several of these light fixtures were just screwed to the ceiling, not even wired to the home’s power system.

The home we eventually bought was owned by an avid shot glass collector. She had big shot glasses, small ones, ones printed with logos from big cities and small towns. Colleges. Hospitals. Even a sheriff’s office. She must have had three hundred, all on display around the home. It was quite the impressive display.

I wonder when my wife and I eventually put our home up for sale if people will have an opinion about my router bit collection…

Routers are extremely versatile tools. They can cut joinery or profiles. They can help you joint a board’s edge or trim a shelf edging flush. They are useless paper weights without bits.

My mom gave me my first router for my birthday many years ago. It was a fixed base Craftsman light duty model. She asked me what I needed to go along with the tool, and I told her I needed some router bits. She was stunned to see the vast array of bits available – and the variety of price points. Eventually, she settled on a small starter kit that served me very well for the first few years.

A quick perusal through a woodworking catalog will show scores of profiles available for sale – from the plain straight bit to the most exotic multi-profile bit. They are sold individually or in large all-encompassing sets. Do you need all of them to woodwork?

Hardly. However, you do need some basics to get the ball rolling. A set of straight cutting bits. A flush trim bit with a follower bearing mounted at the bottom. A chamfer bit. A few different styles of round over bits. Maybe an ogee profile to put a decorative edge. That should get you started.

For me, I bought a set of 20 bits to start – the green ones in the wooden box. Some conventional wisdom says that buying sets of bits is a waste of time. You will use a few bits a lot and most of them very rarely. My experience has been a little different. The set I bought actually has several bits I love to use, and the entire kit does get a workout.

After I purchased my kit, you can see I got my hands on a few other individual models and sets. I have two rabbeting sets – one does larger rabbets, the other smaller. I have a set of slightly undersized plywood bits to cut slots to fit modern cabinet grade plywood. Dovetail bits to work on different jigs. Cope and stick bits to create frame and panel doors…

Wow, that’s quite a collection… I had no idea I had added so many bits.

When you do buy your bits, look for carbide models. Sure, you can modify your high speed steel bits’ profiles to make custom models, but carbide cuts so much more nicely without the need for frequent resharpening. Also, don’t be afraid to pay some money for quality router bits. Sure, you could go to eBay and buy a set of 100 bits for $39, but what are you getting for your money? You will probably be disappointed with the results.

And, never be afraid to experiment with your router profiles. You may have your eye on a fancy profile bit, but break the design down to more basic round overs, coves and chamfers, and you may discover you can use two or three bits you already own to make an exact match.

In order for me to keep my collection – and you to keep yours – in tip top shape, it always pays to follow the standard advice:

- Don’t let the bits knock together. Carbide is tough stuff, but it’s also very brittle. Allowing the bits to knock together while in storage or on your workbench can cause the cutters to chip or shatter.

- Keep ’em clean. Just like saw blades, router bits can get gunk build up on them. Your best bet to keep them clean is to first remove any bearings (if the bits are so equipped) and wipe them down with mineral spirits. You can use an old toothbrush to help scrub the stuff off, but nothing more abrasive than that.

- Tighten them properly. Your router’s collet does a great job grabbing the bits – when it’s properly torqued down. To install a router bit properly, don’t let it bottom out in the collet – pull the bit up a fraction of an inch to keep the bottom of the bit off the router’s spindle. Then, snug up the collet nut and gently twist it to make sure it sets firmly. Don’t crank down on the wrench – you might damage the collet or make it nearly impossible to release.

- Store them where you can see them. If you don’t know which bits you have, how will you now they are available for you to use? Store them out of harm’s way, but someplace where they are easy to get to and put them to use.

Have I bought my last router bit? Not by a long shot. I’m sure a new jig, a new application or a classic molding profile will be announced, and a new Uber-Bit will be promoted which will be capable of joinery, decoration and establishing world peace.

And, when I do buy it, I’ll proudly add it to my collection. It will become a new conversation piece in my living room.

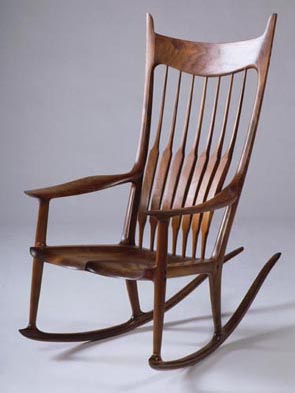

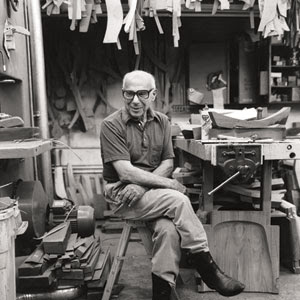

Sam Maloof was an inspiration to many woodworkers. Whether citing his humble beginnings, the organic lines of his projects or the joy he felt while in the shop, woodworkers have found few better examples to emulate than Sam.

Sam Maloof was an inspiration to many woodworkers. Whether citing his humble beginnings, the organic lines of his projects or the joy he felt while in the shop, woodworkers have found few better examples to emulate than Sam.

With the Memorial Day weekend upon us here in the United States, it’s only fitting that I feature a project such as this one.

With the Memorial Day weekend upon us here in the United States, it’s only fitting that I feature a project such as this one. If you can remember the big Tom Hanks’ 1994 hit movie

If you can remember the big Tom Hanks’ 1994 hit movie

Figure can occur nearly anywhere in a tree. According to Eric, “It varies from tree to tree and is different with the different types of figure. In bird’s eye, the whole log might be full of bird’s eye or just part of one side of the log might have it. Sometimes the bird’s eye can even start and stop at different points in the life of the tree. There may be some sort of defect in the log that also causes the figure to start or stop at a certain point in the log.”

Figure can occur nearly anywhere in a tree. According to Eric, “It varies from tree to tree and is different with the different types of figure. In bird’s eye, the whole log might be full of bird’s eye or just part of one side of the log might have it. Sometimes the bird’s eye can even start and stop at different points in the life of the tree. There may be some sort of defect in the log that also causes the figure to start or stop at a certain point in the log.”

While working with figured hardwoods can be a challenge, Joe says going the figured veneer route takes some practice, but is not very different than working with regular unfigured veneers. According to Joe, “some burls may require grain filler, but the basic veneering skills should be able to get you through with no problems.”

While working with figured hardwoods can be a challenge, Joe says going the figured veneer route takes some practice, but is not very different than working with regular unfigured veneers. According to Joe, “some burls may require grain filler, but the basic veneering skills should be able to get you through with no problems.” When I turned 14, my dad had a surprise for me.

When I turned 14, my dad had a surprise for me. No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for.

No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for. When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project.

When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project.