Twas some time before Christmas, when all through the shop

I was just so darned busy, I thought I would drop!

The gift list was hung by the workbench with care.

“If we don’t ship these soon, they’ll never get there!”

I in my apron, glue bottle in hand,

was prepared to work hard, to make my last stand.

Sanding and planing, the dust it did blow,

covering the shop floor like the new-fallen snow.

I struggled and sweated as I wiped off my brow.

“I’m sure I can’t do this… no way or no how.”

Project pieces lay about, both tennon and mortise.

“If I progressed any slower, I just might be a tortoise.”

When what in my offended nose did I smell?

“I can place that aroma! I know it so well…”

When in swang a monkey, hanging high by his tail.

“I’m here to help – together, we won’t fail.”

Of course, it was Iggy, the trained Shop Monkey.

He looked very dapper, his smell was quite funky.

With tool belt cinched tightly around his middle.

He looked young and strong – as fit as a fiddle.

He was 20 inches tall, all covered in fur.

I guess it’s there so, if cold, he wouldn’t say ‘brrr…’

With eye protection on and boots on his feet,

his shop working outfit was completely complete.

“Now, what’s on this list? Something for father and mother…

We’ll finish this job, don’t you worry, my brother.”

But, raising my hand, I told the monkey to hush.

“They’ll all look simply awful if we get in a rush.”

“Not to worry, pal,” said the monkey with glee.

“We’ll get this job done, just you wait and you see.”

And, with fur and tools flying, working hard was a must.

“You know all these tools, in your skills you must trust.”

“Don’t overthink your joinery, lay out and do cut.

If you don’t get a move-on, I’ll just kick your butt.”

With motivation a-plenty, I set out to work.

“You do a good job, Tom, just don’t be a jerk!”

With project pieces cut, the work was quite simple.

I was happy it worked! You could just see my dimple.

The monkey and I, we worked at the bench.

I was no longer bothered by his terrible stench.

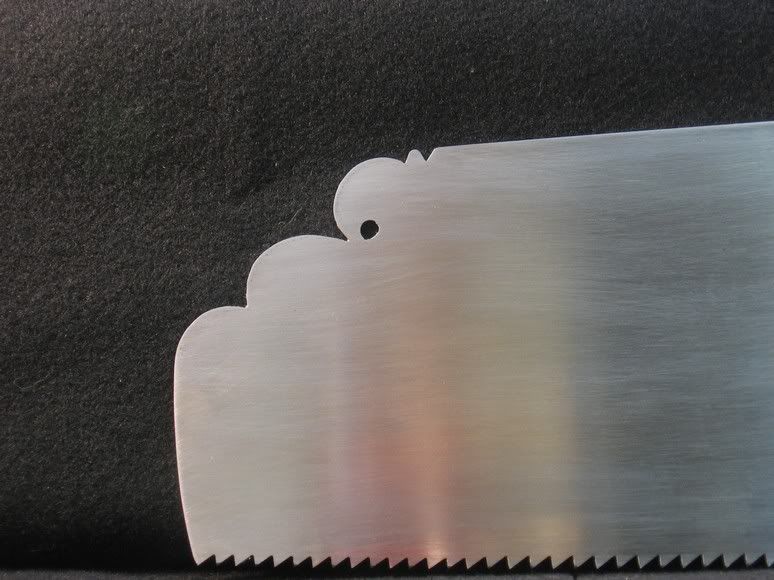

The tools sprung to life, and I was in awe.

Iggy shouted quite loudly, “On router and saw!

On sander and chisel! On spokeshave and plane!”

Our work was quite orderly, the pace was insane!

Together we worked, and with our combined project attack,

there, on the bench, sprung to life nine tiny wine racks.

(A note to my relatives: Right now, shield your eyes

or I will be blowing the big Christmas Surprise!)

The plans we had gotten from our friends there at Wood.

The project looked sweet, the fit was quite good.

From a stack of work pieces all perfectly milled,

from just a plain drawing, these projects distilled.

The frames are held fast with the mortise and tennon.

Try as you might, there’s just no way to bend ’em.

I sanded the pieces, then applied the finish.

Iggy said “You work faster than Popeye on spinach!”

A coat of shellac, a wipe on finish made them pop.

The look amazed both of us, our jaws they did drop.

Eight tiny wine racks, made of maple and sapele.

(That’s a wood from Africa, not Brazil or New Dehli)

Eight were the same, but there was this one

made of dark wood – it looked nice – I had some.

The bottle supports are all of curly maple.

In Iggy’s workshop, that wood is a staple.

And riding on each was a bottle of wine.

Most of them cheap, very few of them fine.

The eight sapele projects they lined up to follow

the dark wooden wine rack, with a red foil on bottle.

The scene it reminded me of old St. Nick’s Sleigh

with Rudolph’s red nose a-lighting the way.

Iggy said, “We got them together, of that there’s no lie,

just try not to touch them ’til the finish is dry.”

“We now need a cheesy photo… go get the missus!”

“What if she won’t?” “Well, go ply her with kisses!”

And so, in a flash, she came with her camera to snap.

She took some pictures, then went back in for a nap.

Iggy looked pleased as I reviewed the shots on the camera.

“That was some hard work. Now, how ’bout a banana?”

And as I handed Iggy a big golden bunch,

he said, “At least – this time – you fed me lunch.”

And, as he swung to a tree and disappeared from sight,

Iggy shouted, “Get to the post office now, not later tonight!”