With care… always.

When people talk about the good old days of hand tools, they often cite the attention paid to the small details. Plane mouths that are machined to tight tolerances. Comfortable handles on chisels. The look and feel of a solid performing work of art.

That’s why you might be surprised that one of the true artisans making new hand saws started out doing rough work.

Andrew Lunn, the owner of Eccentric Toolworks, got what some folks might call a late start in woodworking. “I did have a shop class in junior high school when I was 14 years old. But that wasn’t what really got me going. In fact I didn’t make anything after that until I was 27 years old! I was working in an office and started to get the feeling that I wanted to work more with my hands.” According to Andrew, this career change came totally out of the blue. “I got myself a job working on a construction crew, doing restoration work to fire damaged buildings. It was all really unfocused at first–I knew I felt drawn to working with wood, and that I felt drawn to working with my hands. But I didn’t know if that would mean carpentry, or furniture, or what. So I put together a modest hand tool shop in my garage and began making things by hand. That’s what really got me going.”

Over time Andrew realized he was attracted to the smaller, more skilled tasks that focused his attention. “Several years ago, I got the idea that I wanted to make myself a whole set of hand tools, and that I would in turn use that set of tools to make things. The prospect of making a saw felt particularly interesting so I thought I would start there–and basically I started and just never stopped!”

Today, Andrew makes some of the most comfortable, true cutting – and beautiful – hand saws available for sale. His saws are not mass-produced. Instead, just as a tailor would fit a suit to a customer, each saw is fitted to the individual client placing the order.

“Basically I start with a measurement or two from the customer then send them a poplar prototype of their handle that incorporates those measurements. I get feedback from them and incorporate their input into the actual handle. I also tune the saw for the particular woods the customer will be using.” Andrew ships the saw with the final handles made of beautiful curly maple, cherry, quartersawn beech, or walnut.

Yes, you are reading this correctly. Each saw is truly made by hand in his shop. The handles are shaped entirely by hand. Most of the metalwork is done by hand with files and other hand tools as well. “The saws are tuned and fussed over until I am totally happy with them.”

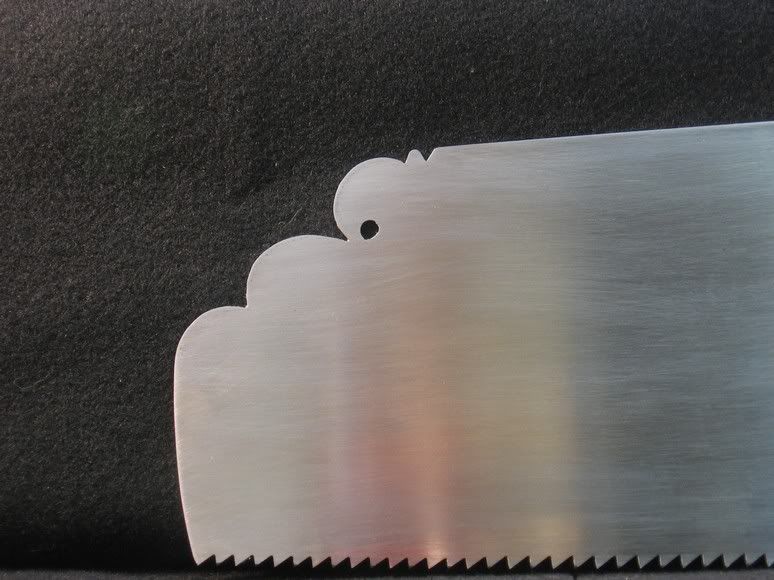

While Andrew could certainly just build some functional plain-Jane looking saws and call it a day, his signature on these tools makes his work truly stand out. Decorative cut outs at the front of the saw make what would normally be a shop workhorse a thing of beauty. “Saws to me represent a creative outlet, so the way they look reflects various openings or possibilities that I thought could be explored. I enjoy the entire design process, both with function and appearance, so as much as possible I try to meld the two into a single fabric.”

When I asked Andrew about his favorite aspect of building these beautiful tools, he had some difficulty identifying it. “I don’t know if I really have one. I like each part of it and get really absorbed while doing it. The metalwork is so important, and has a subtle art to it. The handles, those are a really big deal too. Saws are just very lean tools–there’s nothing there that isn’t important. It takes a lot of concentration and care. That’s why on some of the saws I etch the words, ‘With Care … Always.”