When a new child is born, many woodworkers will go out of their way to craft a cradle to hold the newborn. It’s seen as an honor and a privilege to build the first place where a new person can rest his or her head.

But, what happens at the end of that life? Building a coffin or urn to hold the remains of a beloved family member is no less of an honor or a privilege. And, just as with cradles, the woodworker’s imagination and sense of design can play a tremendous part in shaping that coffin.

Roy “Bud” Davis is a woodworker who truly takes this to heart. At his company, Bert & Bud’s Vintage Coffins, Roy builds classic, artistic and some way out there coffins for his pre-need customers.

For Roy, working with his hands is a family trait. “I come from several generations of people who worked with their hands. “My mother was an expert seamstress and also decorated wedding cakes and birthday cakes that rivaled those done by upscale professionals. Her father caned chairs and she had two brothers, one a master carpenter and the other a master cabinetmaker. On my father’s side, his father was a carpenter and his grandfather was a blacksmith. And believe it or not, my dad’s stepfather was an undertaker. But I can’t claim that I learned anything about woodworking from any of them.”

Roy’s first woodworking experience came in 1962 when he decided to build a cabinet to hold his hi-fi stereo components. While this was quite an accomplishment, he waited 30 years to get back into the craft. That’s when he started building half-scale coffins to commemorate the lives of lost family members. “While working on those commemorative coffins, I thought it would be a great idea to build my own coffin as a work of art and that led me to think, ‘well, why shouldn’t everybody’s coffin be a work of art?'”

Roy has yet to build his own coffin, but that hasn’t stopped him from building others. In fact, he started building classic ‘toe pincher’ coffins to sell to Civil War reenactors. “So far, I have sold only one to a reenactor,” he said, “but I have had a lot of clients who have ordered these for their own use.” And, no, Roy properly pointed out that the ‘toe pincher’ form isn’t just a European convention – it was the most popular style of coffins in the United States from colonial times into the Civil War.

Another event which has affected Roy’s business was the passing of Pope John Paul II in 2005. People around the world were moved by the solemn ceremony, and woodworkers were amazed by the austere coffin the Pope was carried in. “Who could pass up the opportunity to work on a piece with such simple but strong design?” In recent years, reproductions of the Pontiff’s coffin have accounted for about half of his sales.

While these time-honored designs have been a mainstay for Roy, some of his clients have requested interesting and unique designs. “I’ve done a beer bottle coffin for Maxim magazine that was offered as a prize in a nationwide contest; a steamboat coffin for a feature-length film for the Public Broadcasting system (it’s now owned by an actual Mississippi riverboat captain) a dollhouse coffin and a window seat coffin. I never want to shy away from a design or construction challenge.”

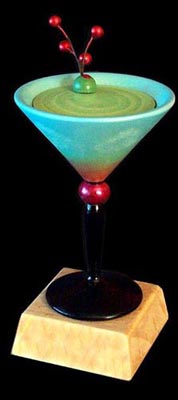

This bold design process also spills over into the cremation urns Roy builds. One design that truly stands out is a piece shaped like a martini glass. “It was made for the mother of a friend of mine. He and I had several conversations about her; he sent me photographs of her in her prime years and told me how she had been a prominent party hostess in Washington, DC in the 1940s and ‘50s. And, she loved martinis. That’s how the process usually goes for all of my urns and for the coffins, too.”

Many woodworkers might be anxious about building a coffin for themselves or their loved ones because they may not believe that they have the necessary skills to build such a specialized piece of woodworking. “A coffin is really just a big box. The joints have to be tight, construction must be sturdy, but the coffin should also look light and graceful.”

While Roy will build a coffin for any customer, the one thing he cannot do is provide coffins on very short notice. “If someone’s relative died suddenly, I wouldn’t be able to help them. I keep no coffins or urns in stock. A kit coffin or plain toe-pincher coffin takes 7 to 10 days to build. Some of the fancier ones can take a couple of months. I build the coffins one at a time in order of when the deposit checks come in. So some customers have to wait until I finish the orders ahead of them. Most often they only have to wait 2 or 3 weeks.”

To help address this pre-need requirement, Roy has built several coffins which can double as window seats, table bases or book shelves. A new model, built from the same style box as the Pope John Paul II replica, serves as a tall clock until needed needed for its intended purpose.

While some people may see this as a macabre practice, Roy considers it to be an honor to be part of the grieving and life memorial process for a family member. “A man described the funeral of his mother who was buried in one of my plain pine toe-pinchers. They filled her coffin half-full of aromatic red cedar shavings, placed her on them and covered her with a blanket made of her Irish clan tartan. Her grandsons carried her on their shoulders while a piper piped her to the grave. It’s very rewarding to play a small yet significant part in a beautiful ceremony like that.”

That’s where programs such as

That’s where programs such as  According to Stephanie Region, Fresh Start’s Director, those staff instructors are the key to the program. “The experience of our staff has traditionally varied over the years – we have had ex-military men as instructors from the Coast Guard and Marines, as well as artists and experienced woodworkers. Currently our staff consists of men and women with art backgrounds and woodworking expertise, as well as experience in teaching and youth development.” Region was quick to point out that the program doesn’t seek to merely supervise kids in a wood shop. “It’s all about engagement with each student. We empower them by putting them in charge of their success. It’s tough for them at the beginning of the program, but they take to it quickly. It’s always amazing to see these transformations.”

According to Stephanie Region, Fresh Start’s Director, those staff instructors are the key to the program. “The experience of our staff has traditionally varied over the years – we have had ex-military men as instructors from the Coast Guard and Marines, as well as artists and experienced woodworkers. Currently our staff consists of men and women with art backgrounds and woodworking expertise, as well as experience in teaching and youth development.” Region was quick to point out that the program doesn’t seek to merely supervise kids in a wood shop. “It’s all about engagement with each student. We empower them by putting them in charge of their success. It’s tough for them at the beginning of the program, but they take to it quickly. It’s always amazing to see these transformations.” What happens after completion of the ten month program? According to Region, “Fresh Start provides three years of aftercare and tracks data and statistics for all graduates during that period. A testament to the relationship built between Fresh Start staff and our students is the fact that our graduates – even students that didn’t graduate for various reasons – keep in contact with us well beyond three years.”

What happens after completion of the ten month program? According to Region, “Fresh Start provides three years of aftercare and tracks data and statistics for all graduates during that period. A testament to the relationship built between Fresh Start staff and our students is the fact that our graduates – even students that didn’t graduate for various reasons – keep in contact with us well beyond three years.” New York City is known as the City that Never Sleeps. The incessant lights, activity and electronic chatter could lead one to believe that NYC is constantly on the move, flying away from tradition at warp speed.

New York City is known as the City that Never Sleeps. The incessant lights, activity and electronic chatter could lead one to believe that NYC is constantly on the move, flying away from tradition at warp speed. The company’s world headquarters is located in the Bush Terminal Market – a giant warehouse facility built in 1907 to service the Brooklyn docks. Now also known as Industry City, it is home to lots of warehouses and a fair number of woodworking shops. The surrounding area is known as Sunset Park and is also on the edge of Green Wood Cemetery – which is considered one of the most beautiful historic cemetery parks in the nation. Joel even gives direction from the local subway line. Just take the D, M, N or R line. And, don’t come too late. “The freight elevator stops running for the lunch hour and at 5 p.m. If you are still in the shop, you’ll have to walk down the stairs to get out.

The company’s world headquarters is located in the Bush Terminal Market – a giant warehouse facility built in 1907 to service the Brooklyn docks. Now also known as Industry City, it is home to lots of warehouses and a fair number of woodworking shops. The surrounding area is known as Sunset Park and is also on the edge of Green Wood Cemetery – which is considered one of the most beautiful historic cemetery parks in the nation. Joel even gives direction from the local subway line. Just take the D, M, N or R line. And, don’t come too late. “The freight elevator stops running for the lunch hour and at 5 p.m. If you are still in the shop, you’ll have to walk down the stairs to get out. For a guy who started woodworking at the local ‘Y’ back when he was seven, Joel has a keen eye toward the history, design and function of classic hand tools. In 1996, he and a partner founded the online Museum of Woodworking Tools, an online showcase of old woodworking tools from shops across the country and the world. “I love the way these old tools look, feel in the hand and function. In many ways, they can work just as fast – or even faster – than power tools and give the user more connection with the wood.”

For a guy who started woodworking at the local ‘Y’ back when he was seven, Joel has a keen eye toward the history, design and function of classic hand tools. In 1996, he and a partner founded the online Museum of Woodworking Tools, an online showcase of old woodworking tools from shops across the country and the world. “I love the way these old tools look, feel in the hand and function. In many ways, they can work just as fast – or even faster – than power tools and give the user more connection with the wood.” While these works of art are appreciated by such notable woodworkers as Frank Klausz, the clientele doesn’t just contain the luminaries of the woodworking world. “You might be surprised with the range of woodworkers we work with. Sure, we have the masters who need a specific tool, but we also get lots of beginners just starting out and some average professionals who need high-quality tools to get stuff done fast.”

While these works of art are appreciated by such notable woodworkers as Frank Klausz, the clientele doesn’t just contain the luminaries of the woodworking world. “You might be surprised with the range of woodworkers we work with. Sure, we have the masters who need a specific tool, but we also get lots of beginners just starting out and some average professionals who need high-quality tools to get stuff done fast.” The router is one of those tools you are not sure that you will need before you buy it, then you wonder how you ever got along without one after you get it. There are scores of tasks a properly equipped and skillfully handled router can tackle. Of course, discovering everything a router can do is frustrating trying to learn on your own. It’s easier if you have a knowledgeable guide along to point out the pitfalls and steer you in the right direction.

The router is one of those tools you are not sure that you will need before you buy it, then you wonder how you ever got along without one after you get it. There are scores of tasks a properly equipped and skillfully handled router can tackle. Of course, discovering everything a router can do is frustrating trying to learn on your own. It’s easier if you have a knowledgeable guide along to point out the pitfalls and steer you in the right direction. Turns out that this child prodigy had to wait another 30 years before he got active again in woodworking. While learning the ropes on his own, he got his first exposure to the router. “It was 1972, and I got a Craftsman 1 HP router with a 1/4″ collet. I was hooked, but surprised to learn that this tool could do a lot only with extra cutters, jigs and other fixtures.”

Turns out that this child prodigy had to wait another 30 years before he got active again in woodworking. While learning the ropes on his own, he got his first exposure to the router. “It was 1972, and I got a Craftsman 1 HP router with a 1/4″ collet. I was hooked, but surprised to learn that this tool could do a lot only with extra cutters, jigs and other fixtures.” Jigs such as the four-faced tenoning jig which I built are very clever and well thought out. Warner offers this and many other completely built jigs for sale on his website. “If you are the kind of woodworker who would rather be building furniture than laying out and building jigs, check out my site. I’m pretty sure you can find the jig that will do the task you need.”

Jigs such as the four-faced tenoning jig which I built are very clever and well thought out. Warner offers this and many other completely built jigs for sale on his website. “If you are the kind of woodworker who would rather be building furniture than laying out and building jigs, check out my site. I’m pretty sure you can find the jig that will do the task you need.” One question Pat gets frequently is about how a router novice should acquire bits. “There are two schools of thought. The first is to buy one of those huge mega sets of 100 or more super-cheap offshore router bits and learn on those. Understand that you may become frustrated with the quality and end up replacing the ones you use the most. But, that’s OK – you will learn a lot. The other is to buy high-quality bits one at a time as you need them. Sure, you may drop some big bucks on a very high quality bit, however, you will enjoy the results for a very long time.”

One question Pat gets frequently is about how a router novice should acquire bits. “There are two schools of thought. The first is to buy one of those huge mega sets of 100 or more super-cheap offshore router bits and learn on those. Understand that you may become frustrated with the quality and end up replacing the ones you use the most. But, that’s OK – you will learn a lot. The other is to buy high-quality bits one at a time as you need them. Sure, you may drop some big bucks on a very high quality bit, however, you will enjoy the results for a very long time.” But, when I needed to do more involved work, those basics at the local big box just didn’t cut it anymore. That’s when you need to turn to a true woodworking supply company. One place I have had quite a but of success buying from is

But, when I needed to do more involved work, those basics at the local big box just didn’t cut it anymore. That’s when you need to turn to a true woodworking supply company. One place I have had quite a but of success buying from is  Dan, and his business partner and wife Linda, took a big risk starting this little company two decades ago. With a mortgage, two young children and a dream, Dan and Linda had to follow the woodworking expo show circuit to make their sales in those early days before a catalog and the Internet. “I think the fondest memories for me of the startup were just being a part of something new. My brother and I used to help stuff envelopes and put labels on mailings at the kitchen table at night. I used to walk to the office after school to help in any way I could. There was an energy there, an excitement, that made things fun to be a part of as a child. It didn’t hurt that we also got to travel and occasionally miss school.” Tim paused. “Ah, the good old days! The shows really were a blast.”

Dan, and his business partner and wife Linda, took a big risk starting this little company two decades ago. With a mortgage, two young children and a dream, Dan and Linda had to follow the woodworking expo show circuit to make their sales in those early days before a catalog and the Internet. “I think the fondest memories for me of the startup were just being a part of something new. My brother and I used to help stuff envelopes and put labels on mailings at the kitchen table at night. I used to walk to the office after school to help in any way I could. There was an energy there, an excitement, that made things fun to be a part of as a child. It didn’t hurt that we also got to travel and occasionally miss school.” Tim paused. “Ah, the good old days! The shows really were a blast.” Eagle America spends a great deal of time evaluating all of the tools they sell to ensure that woodworkers approve. “We have a lot of woodworkers on staff and they are all involved in the product evaluation process. We even survey local woodworkers from time to time to get their opinions on products before we add them to our line. Everyone out there should take comfort in this, knowing that someone at Eagle America who is an actual woodworker has seen, touched and used all of the products we sell.”

Eagle America spends a great deal of time evaluating all of the tools they sell to ensure that woodworkers approve. “We have a lot of woodworkers on staff and they are all involved in the product evaluation process. We even survey local woodworkers from time to time to get their opinions on products before we add them to our line. Everyone out there should take comfort in this, knowing that someone at Eagle America who is an actual woodworker has seen, touched and used all of the products we sell.” While Eagle America is one of those quintessential family businesses, the ‘family’ concept goes far beyond just those blood relatives. “Our staff is fantastic. We are blessed with the talent that we have on our team. From our warehouse to our call center to our Outlet Store and woodworkers on staff, the majority of them have been with us for a while which means they can handle almost every question that is asked or problem that may arise. We take pride in making the customer experience as easy and enjoyable as possible. If we are not meeting people’s needs, we want to know about it so we can do it better the next time. That mindset is a part of everyone here at Eagle America since we would be nothing without our customers!”

While Eagle America is one of those quintessential family businesses, the ‘family’ concept goes far beyond just those blood relatives. “Our staff is fantastic. We are blessed with the talent that we have on our team. From our warehouse to our call center to our Outlet Store and woodworkers on staff, the majority of them have been with us for a while which means they can handle almost every question that is asked or problem that may arise. We take pride in making the customer experience as easy and enjoyable as possible. If we are not meeting people’s needs, we want to know about it so we can do it better the next time. That mindset is a part of everyone here at Eagle America since we would be nothing without our customers!” Take a look at this guy. Who is he?

Take a look at this guy. Who is he? Sometimes, a breath of fresh air is needed to keep everyone on their toes.

Sometimes, a breath of fresh air is needed to keep everyone on their toes. With her degree from San Diego State – along with an Associates of Applied Science degree from the Fashion Institute of Technology and a Masters of Fine Arts from the Rhode Island School of Technology – Amy unleashed her creativity. With her strong background in fine woodworking, joinery, metal work and upholstery, she has created some very interesting pieces developed from a combination of materials. “Wood on its own is challenging, as you know. But any time you add new and different materials to the mix the technical and aesthetic challenges are much greater. Marrying diverse materials requires a greater deal of sensitivity to transitions, textures, and balance. Of course there’s an additional learning curve to working with the new material, plus there are the physical aspects of the different materials to consider.”

With her degree from San Diego State – along with an Associates of Applied Science degree from the Fashion Institute of Technology and a Masters of Fine Arts from the Rhode Island School of Technology – Amy unleashed her creativity. With her strong background in fine woodworking, joinery, metal work and upholstery, she has created some very interesting pieces developed from a combination of materials. “Wood on its own is challenging, as you know. But any time you add new and different materials to the mix the technical and aesthetic challenges are much greater. Marrying diverse materials requires a greater deal of sensitivity to transitions, textures, and balance. Of course there’s an additional learning curve to working with the new material, plus there are the physical aspects of the different materials to consider.” Now a celebrity among woodworking circles, Amy says she hasn’t yet lost the luxury of walking down the street without being mobbed by adoring fans. Her family has been exceptionally supportive of her work, but her interest in woodworking did catch her family a bit by surprise. “I’d always been into typically girly stuff – fashion, make-up, boys you know, the usual. I remember one Christmas I totally threw my parents for a loop when a cordless drill was #1 on my wish list, and high-heeled boots, and lipstick were demoted to #2 and #3.”

Now a celebrity among woodworking circles, Amy says she hasn’t yet lost the luxury of walking down the street without being mobbed by adoring fans. Her family has been exceptionally supportive of her work, but her interest in woodworking did catch her family a bit by surprise. “I’d always been into typically girly stuff – fashion, make-up, boys you know, the usual. I remember one Christmas I totally threw my parents for a loop when a cordless drill was #1 on my wish list, and high-heeled boots, and lipstick were demoted to #2 and #3.” What does the future hold for Amy? Her vision not surprising in the generation that has come of age with instant communication through the Internet is to keep an open dialogue with her viewers. “I’m interested in how people are incorporating greener practices, and the resulting pros and cons. I’d also love to know what your readers would like to see on TV. Are they satisfied with the old guard of TV woodworkers? Are they interested specific techniques, materials, and styles? Also, I’d love, love, love to hear from people with green, creative methods of re-using or recycling saw dust!”

What does the future hold for Amy? Her vision not surprising in the generation that has come of age with instant communication through the Internet is to keep an open dialogue with her viewers. “I’m interested in how people are incorporating greener practices, and the resulting pros and cons. I’d also love to know what your readers would like to see on TV. Are they satisfied with the old guard of TV woodworkers? Are they interested specific techniques, materials, and styles? Also, I’d love, love, love to hear from people with green, creative methods of re-using or recycling saw dust!”