With Woodworkers Safety Day coming up this Wednesday, May 1, it’s the perfect time to take a moment to assess your shop’s safety plans and procedures. Remember that one moment of inattention can lead to an injury that can leave you sidelined from woodworking for weeks, months, potentially forever.

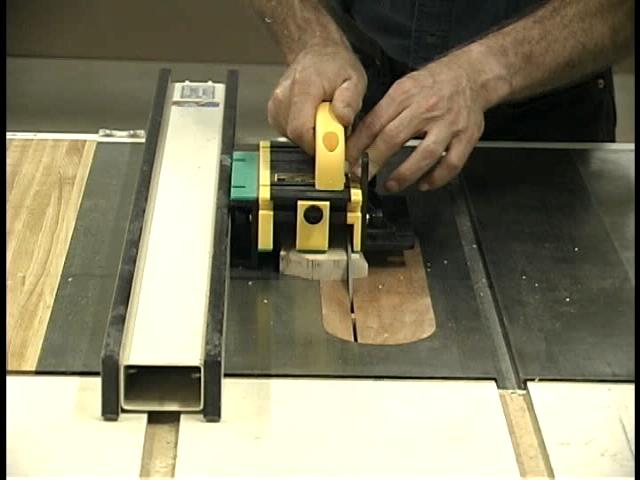

This week, let’s take a look at devices that give you more control and keep your hands farther away from the blades and bits we work with… push sticks and other devices. Whether cut from a simple piece of scrap plywood or elegantly designed devices such as the GRR-Ripper push blocks, these tools can help keep your fingers out of the danger zone and have you work with more confidence. Do you use them regularly, or do you just keep them around the shop to make you look more safe?