Putting a finish on a project is one of those processes people have written books about. Yes, those books are worth their weight in gold. Adding color to – or changing the color of – your project is also a topic that throws a wrench into the works.

Wait a second… what if you could add color to the finish … wouldn’t that at least cut your problems in half?

Or, could it cause an issue, kind of like when someone combined chocolate and peanut butter? Hmmm, or, I mean mmmm…..

Surprisingly, there are already products out there that do this. My first experience with this type of product is made by Minwax – Polyshades. This is basically polyurethane mixed with an oil-based stain. I read the label recommendations very closely, but ended up with a finish that ended up with some pigmented brush streaks.

The instructions on the can state very clearly that you are not supposed to thin the finish at all, but I mixed some thinner into the finish to the point where I could apply it with a rag, and got a better result.

Of course, you can accomplish something similar by mixing some stain into a clear finish you use. In the jar, I have my homebrew finish of boiled linseed oil, thinner and varnish, and I have mixed the two together and finished projects in the past. Of course, you want to match the solvent in the stain or dye and the finish…

Of course, you can accomplish something similar by mixing some stain into a clear finish you use. In the jar, I have my homebrew finish of boiled linseed oil, thinner and varnish, and I have mixed the two together and finished projects in the past. Of course, you want to match the solvent in the stain or dye and the finish…

For instance, the top of my dining room table was primarily done with a clear finish. The first coats looked good, but after a while, I realized I couldn’t get the tone right. So, with a splash of some red oak stain into the finish, I put on the next coat and I was a lot more happy with the results.

Another color and finish combo I have used is made by Watco. It’s sold as Danish oil, and it comes in the standard clear color. But, it also comes in blends that add color to the wood you are finishing. I am using the golden oak mix right now on the surprise project I am building, and it’s matching the color of the wood in the office I am trying to mimic. I have also used the dark walnut color on oak in the past to simulate an arts and crafts look, and it comes out looking good.

It really is a matter of simply wiping the finish onto the wood, letting it sit for a while and then wiping it off. I have yet to have it give me streaking when I apply it, and the surface is that same soft, touchable type of finish that I get from the clear version.

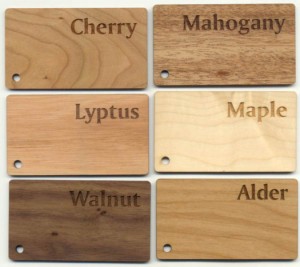

As you can see from these samples… that’s some pretty good looking stuff.