I am trying to make my son Dominic a film geek.

The effort, so far, is going well. We’ve seen movies like Jaws and Close Encounters of the Third Kind, and marveled at the cinematography. We’ve watched movies like Paths of Glory and Lawrence of Arabia and were astounded by the casting. Next up, I want to show him the classic Cold War era knee slapper Dr. Strangelove or: How I Learned to Stop Worrying and Love the Bomb.

Strangelove is one of those gems of a movie that comes along once in a lifetime. The dark humor, the outstanding acting of Peter Sellers and the off-the-wall humor of Slim Pickens – from going through the contents of the survival kit to his climactic riding of the atomic bomb to its target of Laputa, in the Soviet Union.

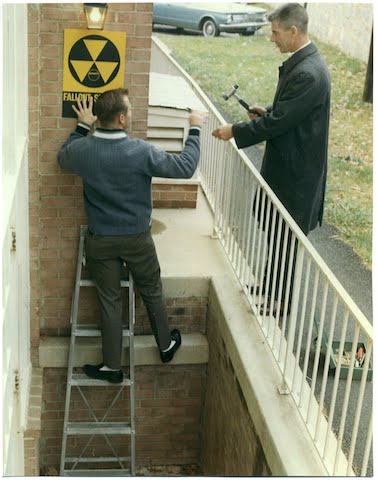

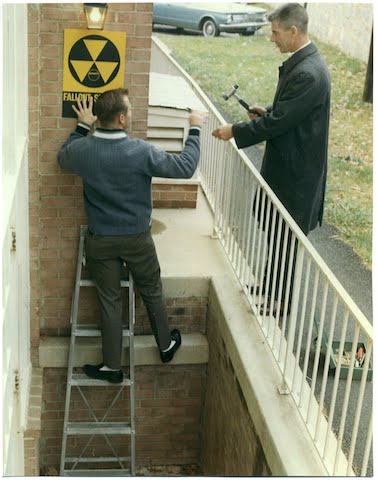

When I think of Strangelove, I always remember a class I took back in college. It was a class, in fact, that was partially responsible for me getting into the disaster response field. It was called The Sociology of Nuclear War. Sure, it sounds strange now, but the class proved to be a hard-hitting study of society’s perception of civil defense, their trust of government and military authorities and the portrayal of our communist adversaries on the other side of the Iron Curtain.

While I can bore you to tears with all I learned in the class, as a woodworker, I keep coming back to an important distinction that my professor made in class when we were speaking about the dangerous weapons: Accuracy vs. Specificity.

I learned that in the world of nuclear weapons, that accuracy was a measure of how many times a warhead would land within a certain error diameter – say 50% of the warheads would land within a 2 mile radius of a target. Specificity, on the other hand, was a measure of how ‘targetable’ a device was. Could it hit a hardened missile silo, or would it be better used on a large, unarmored target?

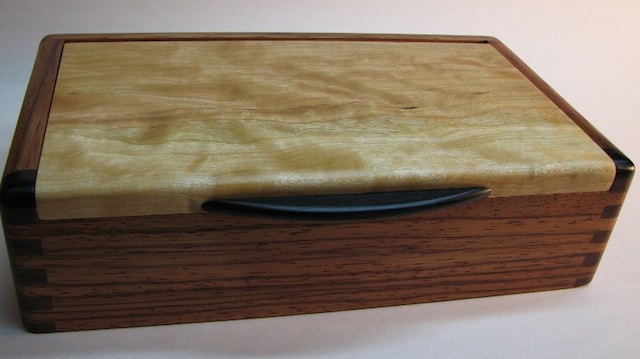

When it comes to woodworking and we are building projects, a very similar concept comes into play. Accuracy is the ability to mill and cut pieces to exact measurements. Say you are building a project from a commercially available plan. If the drawer runners need to be exactly 1/4″ by 1/4″ by 6 5/8″ long, can you cut that piece accurately enough to recreate the project as it was built on the designer’s workbench? Remember, these dimensions are checked time and again to ensure they are accurate enough for you to build the piece in your shop as designed.

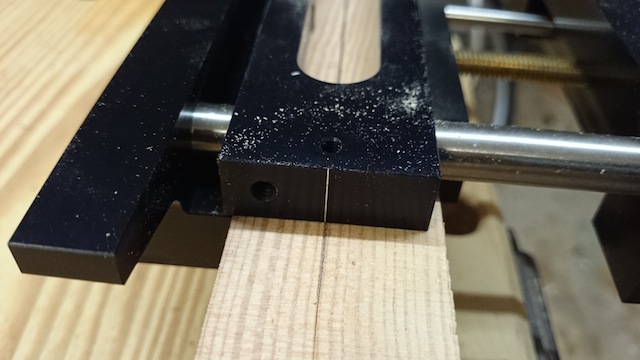

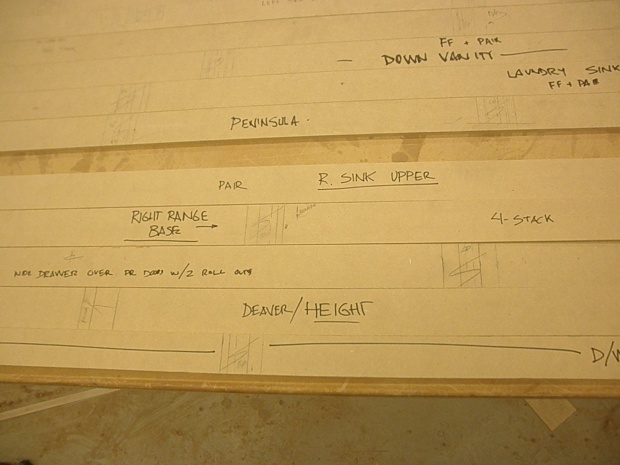

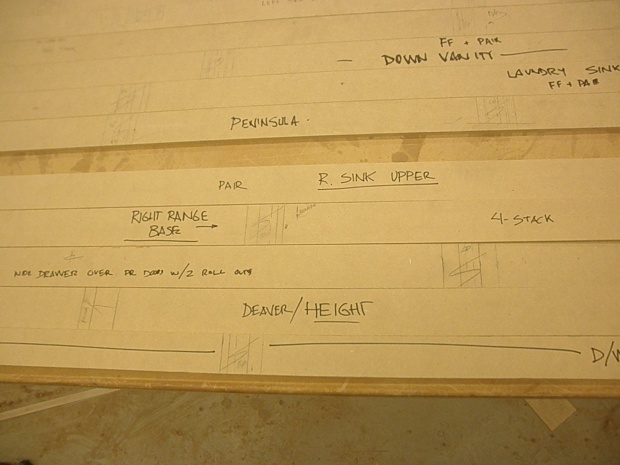

Specificity, however, in woodworking is also known by other names such as relative dimensioning. In other words, can you carefully dimension and cut a piece of wood to fit a specific part of a project you are building? This too is an important skill to have in your repertoire, because, in the real world, not everything is square, true and the exact size you need it to be. When it comes to specificity in woodworking, who cares if the piece is 7 23/64″ exactly? What you are really going for is a snug fit with no gap. This is the world where story sticks come into play.

Which is better? A ha! That’s a trick question. The answer is they are both very important, and both skills need to be honed in order to ensure that you can build exactly what you want. Accuracy ensures that your project will end up the right size, and specificity ensures that each component fits accurately.