When I turned 14, my dad had a surprise for me.

When I turned 14, my dad had a surprise for me.

He handed me a new razor, a can of shaving cream and showed me how to shave. Even though I was using a safety razor, I still managed to cut myself. Ahh, the joys of inexperience.

Since then, I’ve had a love/hate relationship with the male rite of shaving my face. Some days, I walk away from the sink in the morning with a perfect shave – feeling fresh and ‘kissably smooth’ according to my wife. Other days, I swear I took my belt sander to my face – all red, irritated and scraped up. Since I’m not sure which kind of shave I’ll get, I tend to avoid shaving if at all possible. Sure, it’s tough to get moving on a Monday morning, but at least my face had a weekend’s rest from the blade.

Later on, when I became a hobby woodworker, I ran into another group of folks who liked to shave – a lot. And, not just to keep up appearances.

Some of the woodworkers I spoke with had an extreme fascination with sharpening and honing their plane irons and chisels to razor-sharp perfection. And, with a salesman’s zeal, these folks will call friends and neighbors over to demonstrate how well their blades can clear their arm or leg hairs. It’s a stunning trick, and I have to hand it to them. They do have persistence.

But, is sharpening to that keen of an edge really necessary for woodworking?

No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for.

No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for.

But, when should you say ‘when’ during the sharpening process?

Hey, I used to fall into the trap of meticulously sharpening my chisels and plane irons. There were times when I used to fuss for half an hour over each edge, honing until the back face of the bevel was reflective enough to signal rescue planes if I was marooned on a desert island. Then I would flip the blade over and work on the bevel, building a lustrous shine before tipping the edge up enough to create the perfect one degree microbevel.

And, yes, I would then shave arm hairs to prove to myself that the chisels were ready for use.

While sweating over a sharpening job in my shop one hot Florida summer afternoon, the little voice of reason in my head started screaming at me. “Can we get this over with? It’s hot, and I want to go inside! Besides, how much better can that edge really get?”

It was that afternoon when I changed my sharpening procedure and added an important step. I went to the scrap bin and pulled out a piece of hardwood and clamped it in my bench vise. I took the chisel – still far from its mirror-like destiny – and started paring the edge. The wood yielded. Easily. In an end grain cut. With little effort on my part. Wow.

I was stunned to see how much earlier in the process I could stop with minimal – if any – effect on the cutting ability. Not only could I save myself quite a bit of time while sharpening, this result also convinced me that I could sharpen my tools more frequently, without having to take the tool through the onerous process of honing to that fine degree.

My mind then turned to previous episodes of the Woodwright’s Shop, hosted by Roy Underhill. I have watched Roy for years, working with his planes and chisels in his throwback workshop. Sure, his tools are plenty sharp, but not so reflective, if you catch my meaning.

While I was reading the Woodwright’s Companion, I noticed that Roy also touched on the fact that woodworkers relied on quarried stones to bring their edges into true. No, these old masters didn’t get into a heated debate about the micron size of the abrasive they were using – they used the best stones possible to get their blades sharp and then returned to the bench.

And, when they shaved their faces, they didn’t use plane irons – they used straight razors made with much finer and more flexible blades.

When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project.

When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project.

I will also use a piece of MDF with some of the Lee Valley green honing compound to put an even finer edge on the edge, but that’s it.

Will woodworkers still hone their irons and chisels to a mirror finish? Of course they will. There are also people who will shop for stereo systems that faithfully reproduce tones well outside of the normal range of human hearing. Hey, to each his or her own, and if leaving bare patches of skin on their arms is an outward sign of their sharpening prowess, more power to them.

I already have a mirror in my bathroom so I can see what I’m doing when I pick up my razor to get ready for work in the morning.

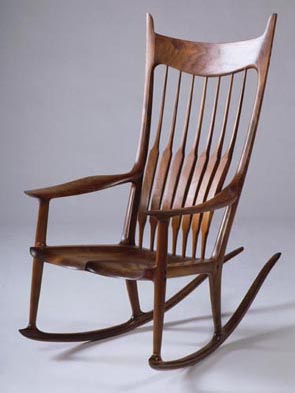

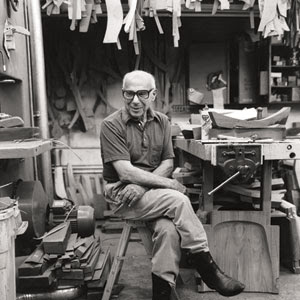

Sam Maloof was an inspiration to many woodworkers. Whether citing his humble beginnings, the organic lines of his projects or the joy he felt while in the shop, woodworkers have found few better examples to emulate than Sam.

Sam Maloof was an inspiration to many woodworkers. Whether citing his humble beginnings, the organic lines of his projects or the joy he felt while in the shop, woodworkers have found few better examples to emulate than Sam.

With the Memorial Day weekend upon us here in the United States, it’s only fitting that I feature a project such as this one.

With the Memorial Day weekend upon us here in the United States, it’s only fitting that I feature a project such as this one. If you can remember the big Tom Hanks’ 1994 hit movie

If you can remember the big Tom Hanks’ 1994 hit movie

Figure can occur nearly anywhere in a tree. According to Eric, “It varies from tree to tree and is different with the different types of figure. In bird’s eye, the whole log might be full of bird’s eye or just part of one side of the log might have it. Sometimes the bird’s eye can even start and stop at different points in the life of the tree. There may be some sort of defect in the log that also causes the figure to start or stop at a certain point in the log.”

Figure can occur nearly anywhere in a tree. According to Eric, “It varies from tree to tree and is different with the different types of figure. In bird’s eye, the whole log might be full of bird’s eye or just part of one side of the log might have it. Sometimes the bird’s eye can even start and stop at different points in the life of the tree. There may be some sort of defect in the log that also causes the figure to start or stop at a certain point in the log.”

While working with figured hardwoods can be a challenge, Joe says going the figured veneer route takes some practice, but is not very different than working with regular unfigured veneers. According to Joe, “some burls may require grain filler, but the basic veneering skills should be able to get you through with no problems.”

While working with figured hardwoods can be a challenge, Joe says going the figured veneer route takes some practice, but is not very different than working with regular unfigured veneers. According to Joe, “some burls may require grain filler, but the basic veneering skills should be able to get you through with no problems.” When I turned 14, my dad had a surprise for me.

When I turned 14, my dad had a surprise for me. No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for.

No one is going to argue with the fact that sharp tools are a pleasure to use. They are safer, cut more cleanly and make your shop tasks a whole lot more pleasant. Dull tools will ruin more boards – and hurt more woodworkers – than we can ever fully account for. When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project.

When I buy an old plane or chisel, I will regrind the bevel on my Work Sharp 2000, and then either use the Scary Sharp method (sandpaper glued to a piece of float glass) or the DMT Diamond Stone my wife gave me a few birthdays ago. I’ve gotten so I can regrind and hone an old chisel in about five minutes, and have it cutting easily through wood. It takes even less time to hone blades that just need some touching up after a project. It’s any woodworker’s worst nightmare – an injury while working in the shop. Whether a kickback from a table saw, a slip of a chisel, a router bit gone wild or something much worse, a woodworking injury can make you sit up and take notice.

It’s any woodworker’s worst nightmare – an injury while working in the shop. Whether a kickback from a table saw, a slip of a chisel, a router bit gone wild or something much worse, a woodworking injury can make you sit up and take notice. In his Bellevue, Washington shop, Peter Loh uses beautiful boards to create unique works of functional art.

In his Bellevue, Washington shop, Peter Loh uses beautiful boards to create unique works of functional art.