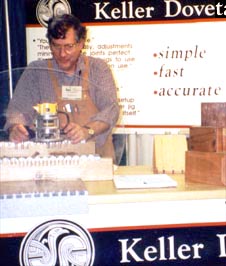

Oh, what the heck. This is the other article I have had in the hopper for more than a year. David Keller is a legend in woodworking, and even though I don’t have a photo of him, his story is just too good to sit on my hard drive anymore!

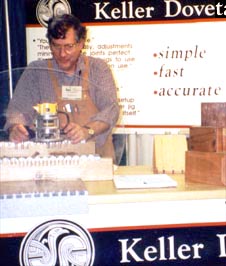

If you can go to your shop and cut through dovetails without having to reach for a hand saw and chisels, you may want to stop and offer some thanks to David Keller. After all, David was one of the brain trust who invented the router-driven through dovetail jig way back in the mid 1970’s. While the owner of Keller Dovetail Jigs is well known in woodworking circles, his path to the level of accomplishment he has achieved didn’t really start with woodworking at all.

David actually graduated with a degree in social psychology and worked at a state hospital in Michigan before he realized that it just wasn’t for him. “I knew I was in trouble when I discovered that there were just too many insane people that I had to work with.”

After looking for a big career switch, he moved west to try his hand at furniture making. He bounced around working odd jobs – such as taking an apprenticeship at a reupholstry shop (he didn’t like it one bit ) while looking for the dream furniture. His search, however, wasn’t very successful. “You have to remember that during that time period, custom furniture making wasn’t really done. People were buying machine-made pieces, and the whole idea of craft building hadn’t yet caught on.” But, David was soon to discover that he was in the right place at the right time.

In a move to the San Francisco Bay area, he met up with noted woodworker Art Carpenter. “It was a very interesting time. We met after lunch on a cold day back in ’71. He liked my enthusiasm and brought me on board. I started out sweeping the floor and sanding for Art for a whopping two dollars an hour. But I learned so much there.

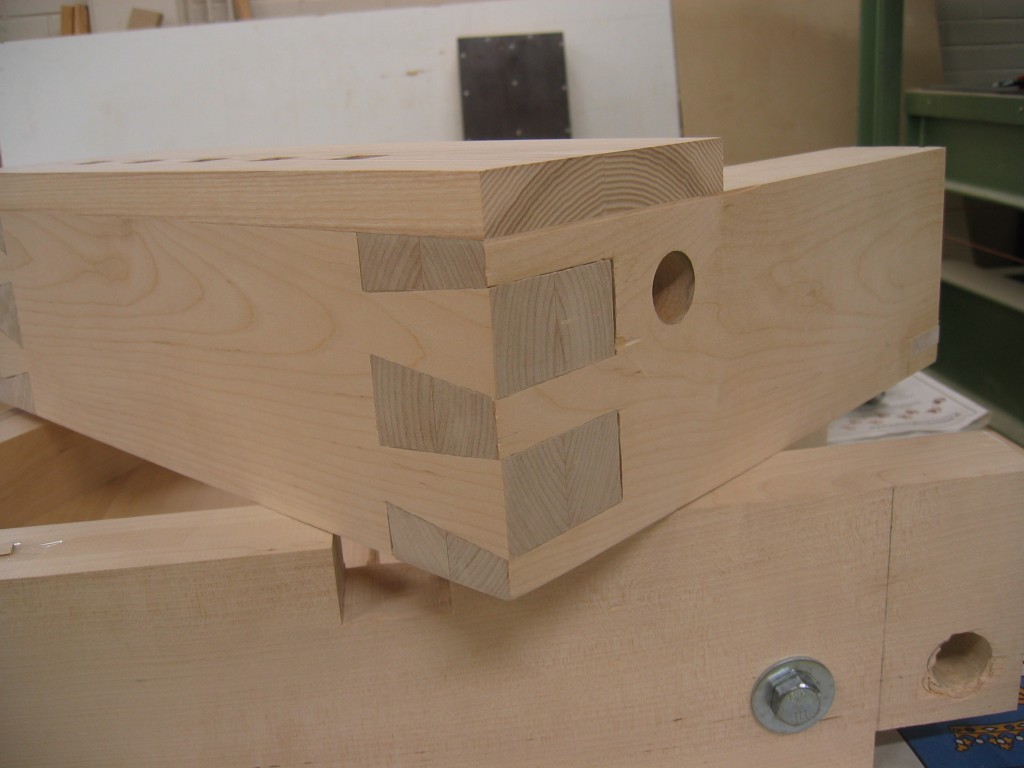

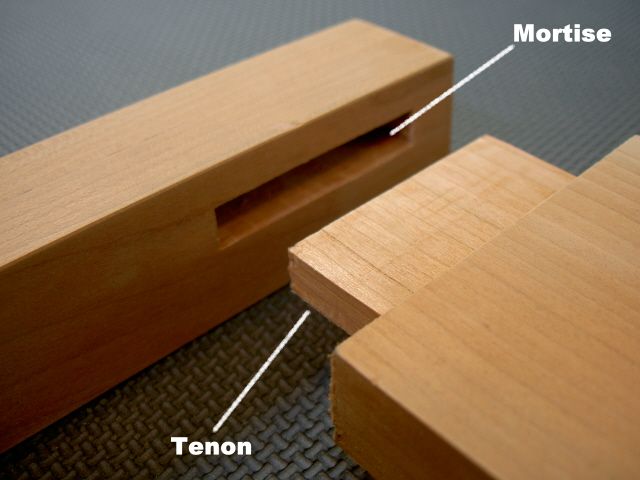

Carpenter was well known for his California Roundover school of furniture design, which dictated a very smooth, tactile approach to building furniture. Another thing Art demanded was that all casework be dovetailed. But, all those dovetail joints took time to cut by hand. Surely, there had to be an easier way…

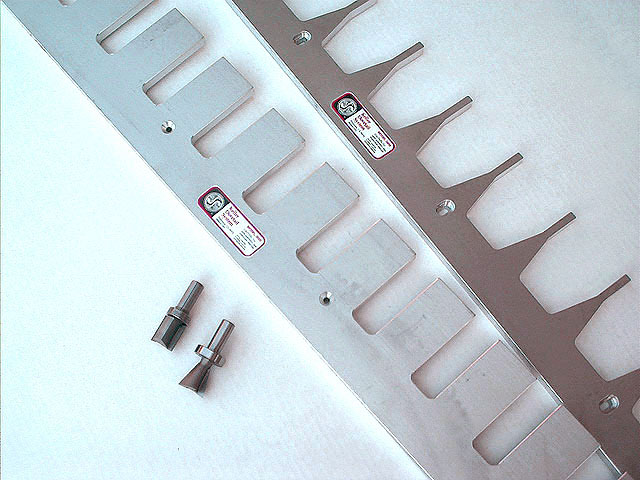

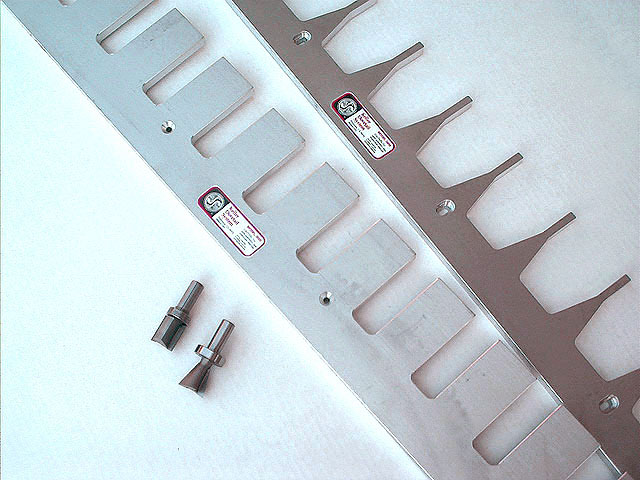

Carpenter first cut some plexiglass jigs to work as a template for through dovetail work. They worked OK, but David realized that if the work was going to be tight and consistent, it was going to require some precision machining. So, drawing upon his extensive knowledge of drafting – that he remembered from a high school drafting class – and prepared plans for a machine shop in San Jose to cut out. That modest jig he designed is still sold today as the model 3600.

David’s recommendation to improve the router bits even led to the invention of a very commonly used router bit. “By doing away with a guide collar and going to a ball-bearing guide, we effectively designed the first flush-trim bit.”

The rest, as they say, is history.

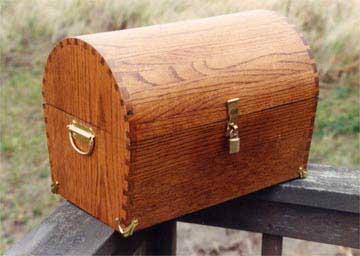

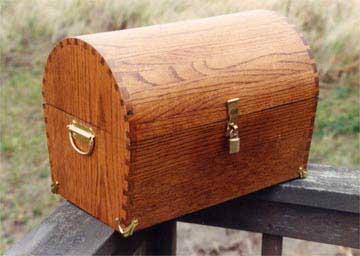

When you succeed, there are critics. After all, hand cut dovetails are a signature joint for woodworkers the world over. Some woodworkers who rely on the hand-cut methods have remarked that a jig that allows the average woodworkers to make this venerable joint ‘cheapens’ the craft. “For those who like to cut your dovetails by hand, more power to you. That’s a skill that is very enjoyable and very centering. But, if you want to get a project done with properly fitted dovetails in a reasonable amount of time, using a jig and router provides excellent results and allows you more time to design, assemble and finish.”

In fact, a common criticism of router-cut dovetails is a ‘generic’ feel they have, with pins and tails at precise intervals. Some jigs can overcome this during their setup, but that can be tedious. “We’ve found that users of the Keller jig have been very creative in their suggestions and recommendations. The simplicity of the jig gives the user a flexibility to variably space the tails and pins, or even dovetail around curves.”

While many other companies have released through dovetail jigs since Keller first released his in 1976, the product’s longevity is a strong indicator of its worthiness. “Yes, even after all these years, the jig’s design is still durable, useful, easy to set up and the damned thing still works well!” In fact, one of the original jigs Keller built back in 1976 is still in operation at a Salt Lake City high school wood shop.

Of course, I had to ask if Keller ever had the opportunity to do any woodworking on his own nowadays. “Heck no! You should see what passes for my shop. Every horizontal surface is covered with jigs to mail, manuals, magazines – the works,” Keller laughed. “In fact, we had to shoot the instructional video in someone else’s shop – mine was just too crowded.”

It sounds like Keller might be a victim of his own success.

You can find reviews, customer testimonials and even order a jig online at www.kellerdovetail.com, or by calling 1-800-995-2456.